Machine learning deployment in high-stakes construction environments demands a fundamentally different approach from conventional software implementation. When structural integrity, worker safety, and multi-million dollar investments hang in the balance, traditional ML validation methods fall short. AI-powered risk management systems must achieve near-perfect accuracy while operating under extreme conditions.

Recent catastrophic failures in automated construction systems have demonstrated that even 99% accuracy isn’t sufficient when lives are at stake. Industry leaders are now implementing rigorous three-tier validation frameworks: controlled testing environments, supervised field trials, and continuous monitoring systems that can detect and respond to edge cases in real-time.

This article examines the critical methodologies, validation protocols, and fail-safe mechanisms required to deploy machine learning systems in high-risk construction applications. Drawing from real-world case studies and expert insights, we’ll explore how leading firms are successfully implementing ML solutions while maintaining unwavering safety standards and regulatory compliance.

Real-Time Risk Assessment Through Machine Learning

Sensor Integration and Data Collection

Effective risk monitoring in construction projects increasingly relies on advanced IoT sensors in construction and sophisticated data collection systems. These sensors form an interconnected network that continuously monitors critical parameters such as structural integrity, equipment performance, environmental conditions, and worker safety metrics.

Modern sensor integration typically includes strain gauges for structural monitoring, accelerometers for vibration analysis, environmental sensors for air quality and temperature monitoring, and proximity sensors for safety zone enforcement. These devices transmit real-time data to centralized systems where machine learning algorithms process and analyze the information for potential risk indicators.

Data collection methods have evolved to incorporate both structured and unstructured data sources. Structured data comes from calibrated sensors and standardized reporting systems, while unstructured data includes visual inputs from surveillance cameras, drone footage, and worker feedback systems. The integration of these diverse data streams enables a comprehensive risk assessment approach.

Key considerations for successful sensor deployment include:

– Strategic placement of sensors at critical monitoring points

– Robust connectivity infrastructure for reliable data transmission

– Regular calibration and maintenance protocols

– Data validation and quality assurance processes

– Secure data storage and transmission systems

This multi-layered approach to data collection provides the foundation for machine learning models to identify patterns, predict potential risks, and trigger appropriate preventive measures before incidents occur.

Predictive Analytics in Safety Management

Predictive analytics in safety management leverages machine learning algorithms to analyze historical incident data, sensor readings, and environmental conditions to forecast potential safety risks before they materialize. By processing vast amounts of real-time data from multiple sources, including wearable devices, equipment sensors, and weather stations, these systems can identify patterns that typically precede accidents or hazardous situations.

Construction firms implementing predictive analytics have reported significant improvements in their safety metrics. For example, a leading construction company reduced workplace incidents by 30% after deploying ML-powered predictive systems that monitored worker fatigue, equipment maintenance patterns, and environmental hazards. These systems continuously analyze factors such as worker movement patterns, equipment vibration signatures, and structural stress indicators to generate early warning alerts.

The effectiveness of predictive analytics relies on three key components: data collection infrastructure, machine learning models trained on industry-specific datasets, and real-time alert systems. Advanced algorithms can detect subtle correlations between various risk factors, such as the relationship between weather conditions, worker scheduling, and accident probability. This enables project managers to make proactive decisions about resource allocation, scheduling, and safety protocols.

Modern predictive systems can also integrate with Building Information Modeling (BIM) platforms to create comprehensive safety forecasts that account for project-specific challenges and evolving site conditions. This integration enables dynamic risk assessment and automated safety protocol adjustments based on changing project parameters.

Critical Applications in High-Risk Construction Scenarios

Structural Integrity Monitoring

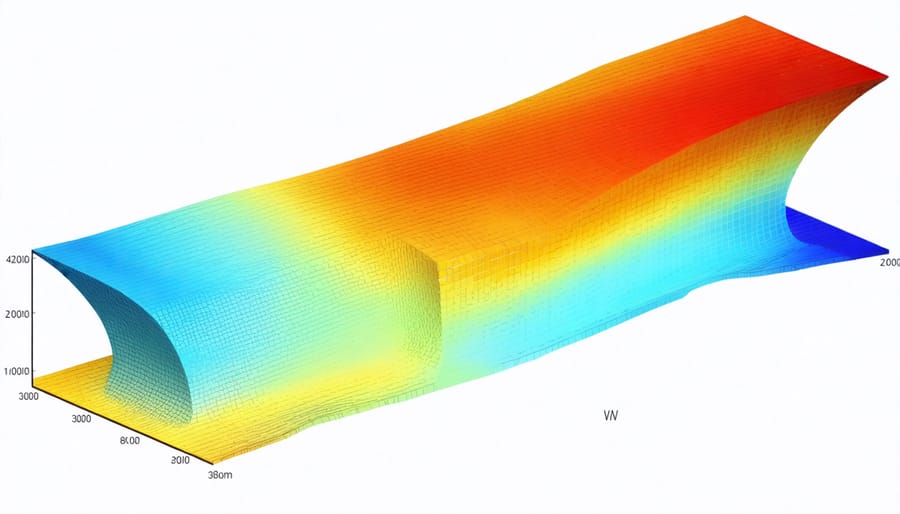

Machine learning algorithms are revolutionizing structural integrity monitoring during construction by providing real-time analysis of building stability and potential risks. These systems utilize a network of IoT sensors strategically placed throughout the structure to collect continuous data on key parameters including vibration patterns, load distribution, and material stress levels.

Advanced ML models process this sensor data to detect subtle changes that might indicate structural issues before they become critical. By analyzing historical data patterns and comparing them with current readings, these systems can predict potential failures and alert construction teams to take preventive action.

For example, deep learning algorithms can identify unusual settlement patterns in foundations by processing data from displacement sensors and comparing it against expected behavior models. Similarly, neural networks analyze vibration signatures to detect potential weaknesses in structural elements or unexpected load distributions.

Construction teams benefit from ML-powered monitoring through:

– Continuous 24/7 structural assessment

– Early warning system for potential instabilities

– Real-time load distribution analysis

– Automated stress-point identification

– Predictive maintenance scheduling

Recent implementations have shown that ML-based monitoring systems can reduce structural failure risks by up to 45% while improving construction efficiency. These systems are particularly valuable in high-rise construction and complex architectural designs where traditional monitoring methods may be insufficient.

The integration of ML with Building Information Modeling (BIM) further enhances monitoring capabilities by providing context-aware analysis and visualization of structural health data, enabling better decision-making during critical construction phases.

Equipment Operation Safety

Machine learning technologies are revolutionizing equipment operation safety in high-risk construction environments. By integrating advanced AI algorithms with existing machinery systems, construction companies can significantly reduce operational risks while enhancing efficiency. These systems work in conjunction with robotics in construction safety to create comprehensive safety protocols.

Real-time monitoring systems equipped with ML capabilities can predict potential equipment failures before they occur, enabling proactive maintenance and reducing the likelihood of accidents. These systems analyze various parameters including vibration patterns, temperature fluctuations, and operational metrics to identify anomalies that might indicate impending issues.

The implementation of ML-powered operator assistance systems has shown remarkable results in preventing accidents caused by human error. These systems provide real-time guidance, monitor operator fatigue levels, and automatically enforce safety protocols when necessary. For instance, intelligent proximity detection systems can automatically halt equipment operation when unauthorized personnel enter restricted zones.

Advanced computer vision algorithms continuously monitor work zones, identifying potential hazards and ensuring proper equipment usage. This technology has proven particularly effective in complex construction environments where multiple pieces of heavy machinery operate simultaneously. By analyzing historical accident data and current operational patterns, these systems can predict high-risk scenarios and trigger preventive measures accordingly.

Worker Safety Enhancement

Machine learning algorithms have revolutionized worker safety monitoring by providing real-time analysis of personal protective equipment (PPE) compliance and worker behavior patterns. Advanced computer vision systems can now continuously monitor construction sites, instantly detecting whether workers are wearing required safety gear such as hard hats, safety vests, and protective eyewear.

These AI-powered systems utilize deep learning models trained on vast datasets of construction site imagery to achieve detection accuracy rates exceeding 95%. When violations are detected, supervisors receive immediate alerts, enabling swift corrective action before accidents occur. The technology also tracks patterns of PPE compliance across different times, locations, and work crews, helping management identify areas requiring additional safety training or supervision.

Beyond PPE monitoring, machine learning systems analyze worker movement patterns and behaviors to identify potential safety risks. By processing data from wearable sensors and surveillance cameras, these systems can detect unsafe practices such as working in restricted areas, improper lifting techniques, or dangerous proximity to heavy machinery. The collected data provides valuable insights for updating safety protocols and implementing targeted interventions.

Case studies from major construction firms demonstrate significant improvements in safety metrics after implementing ML-based monitoring systems. One notable project reported a 60% reduction in PPE violations and a 45% decrease in near-miss incidents within six months of deployment. These systems prove particularly valuable in high-risk environments where traditional supervision methods may be limited or impractical.

Implementation Challenges and Solutions

Data Quality and System Reliability

In high-risk construction applications, the reliability of machine learning systems hinges critically on data quality and system dependability. Poor data quality can lead to incorrect predictions, potentially compromising safety and project outcomes. Construction firms must implement rigorous data validation protocols, including regular calibration of sensors, verification of input data, and systematic quality checks throughout the data collection process.

System reliability requires a multi-layered approach, incorporating redundant systems and fail-safes. As digital security in construction becomes increasingly critical, organizations must ensure their ML systems are protected against both data corruption and cyber threats.

Key considerations include:

– Data validation frameworks that verify accuracy and completeness

– Regular system audits and performance monitoring

– Backup systems for critical operations

– Clear protocols for system failures

– Continuous monitoring of data quality metrics

Industry leaders recommend implementing a comprehensive data governance strategy that includes regular testing of ML models against known benchmarks, systematic error tracking, and established procedures for model retraining when performance degrades. This approach ensures that high-risk applications maintain their reliability while delivering consistent, accurate results that construction professionals can trust for critical decision-making processes.

Integration with Existing Safety Protocols

Integrating machine learning systems into existing safety protocols requires a methodical approach that prioritizes both technological advancement and established safety standards. Begin by conducting a comprehensive audit of current safety procedures and identifying potential integration points where ML systems can enhance rather than disrupt existing workflows.

Create a detailed implementation roadmap that includes parallel testing phases, allowing the ML system to run alongside traditional safety measures before full deployment. This approach enables validation of the ML system’s accuracy while maintaining established safety standards.

Establish clear communication channels between ML systems and existing safety infrastructure. This includes developing standardized alert protocols, ensuring emergency override capabilities, and creating backup systems for critical operations. Document all integration procedures and update safety manuals to reflect new ML-enhanced processes.

Train safety personnel and operators on both the technical aspects of the ML system and its interaction with existing safety protocols. Regular drills should incorporate ML-triggered scenarios alongside traditional emergency responses.

Implement a continuous monitoring system that tracks the performance of integrated ML solutions against established safety metrics. This should include regular audits, performance reviews, and adjustment periods based on collected data.

Finally, maintain detailed documentation of all integration steps, including risk assessments, testing results, and modification histories. This creates a clear audit trail and facilitates future updates or adjustments to the integrated system.

Future Implications and Industry Impact

The integration of machine learning in high-risk construction applications is poised to revolutionize the industry over the next decade. As computational power increases and algorithms become more sophisticated, we can expect to see more precise risk prediction models and automated decision-support systems becoming standard practice across construction projects.

Industry experts predict that real-time risk monitoring will become increasingly prevalent, with IoT sensors and ML algorithms working in tandem to provide instantaneous risk assessments. This evolution will enable project managers to make proactive decisions rather than reactive corrections, potentially reducing accident rates by up to 50% according to recent industry forecasts.

The convergence of Building Information Modeling (BIM) with ML algorithms will create more comprehensive risk management systems. These integrated platforms will not only identify potential hazards but also suggest optimal mitigation strategies based on historical data and current project conditions. This advancement is expected to reduce project delays by 30% and cut insurance costs by up to 25%.

Emerging technologies like digital twins, powered by ML algorithms, will enable construction teams to simulate and test high-risk operations in virtual environments before execution. This capability will significantly reduce the likelihood of accidents and optimize resource allocation during complex construction phases.

The workforce impact will be substantial, with an estimated 60% of construction professionals requiring some level of ML literacy by 2025. This shift will create new roles such as construction data scientists and risk analytics specialists, while traditional roles will evolve to incorporate ML-driven decision-making tools.

However, challenges remain. The industry must address data privacy concerns, standardize ML implementation protocols, and develop robust validation frameworks for AI-driven decisions in high-risk scenarios. Success will depend on establishing clear regulatory guidelines and industry-wide standards for ML applications in construction safety.

As these technologies mature, we can expect to see a fundamental transformation in how the construction industry approaches risk management, leading to safer worksites, more efficient operations, and improved project outcomes.

The successful implementation of machine learning in high-risk construction applications requires a strategic approach combining robust data management, skilled personnel, and proper risk assessment protocols. Organizations must prioritize data quality, invest in comprehensive training programs, and establish clear governance frameworks to ensure reliable ML outcomes. Regular system audits, continuous monitoring, and adaptive maintenance strategies are essential for maintaining optimal performance. Construction professionals should start with smaller, well-defined projects before scaling to more complex applications, ensuring each implementation phase is thoroughly validated. By following these guidelines and maintaining a balanced approach between innovation and safety, construction companies can effectively leverage machine learning to enhance project outcomes while minimizing potential risks. The future of construction safety and efficiency lies in the thoughtful integration of ML technologies, supported by strong organizational commitment and industry best practices.