Building energy efficiency standards have become the cornerstone of modern construction, driving a 40% reduction in commercial energy consumption over the past decade. As global energy costs surge and environmental regulations tighten, implementing robust building energy management strategies has evolved from a regulatory requirement to a critical business imperative.

The International Energy Conservation Code (IECC) and ASHRAE 90.1 standards now mandate comprehensive performance metrics that reshape how we design, construct, and operate commercial buildings. These standards integrate cutting-edge thermal envelope requirements, advanced HVAC optimization protocols, and intelligent lighting control systems—delivering measurable energy savings while ensuring occupant comfort and operational efficiency.

For construction professionals and building owners, mastering these standards isn’t just about compliance—it’s about creating high-performance buildings that demonstrate excellence in both environmental stewardship and fiscal responsibility. By incorporating these requirements early in the design phase, projects can achieve up to 30% greater energy efficiency compared to conventional buildings, while significantly reducing long-term operational costs.

Current Global Energy Efficiency Standards

ASHRAE 90.1 and IECC Compliance

ASHRAE Standard 90.1 and the International Energy Conservation Code (IECC) represent the cornerstone of building energy efficiency regulations in the United States and globally. These standards establish minimum requirements for energy-efficient design and construction, with each updated version introducing more stringent requirements to reduce energy consumption.

ASHRAE 90.1 primarily focuses on commercial buildings, setting specific criteria for building envelope, HVAC systems, lighting, and power systems. The standard employs two compliance paths: the prescriptive path, which provides specific requirements for individual building components, and the performance path, which allows for energy modeling to demonstrate equivalent or better performance.

The IECC complements ASHRAE 90.1 by providing comprehensive energy conservation requirements for both commercial and residential construction. It includes detailed provisions for mechanical systems, lighting controls, and building envelope requirements. Many jurisdictions have adopted either ASHRAE 90.1 or IECC as their baseline energy code, often with local amendments to address specific regional conditions.

Key compliance requirements include:

– Minimum insulation values for walls, roofs, and foundations

– Maximum lighting power densities

– HVAC equipment efficiency ratings

– Building envelope air leakage limits

– Mandatory commissioning requirements

Recent updates to both standards have emphasized the integration of renewable energy systems and advanced building controls, reflecting the industry’s shift toward net-zero energy buildings and enhanced operational efficiency. Construction professionals must stay current with these evolving standards to ensure project compliance and optimal energy performance.

Regional Variations and Requirements

Building energy efficiency standards exhibit significant variations across different regions and jurisdictions, reflecting local climate conditions, energy resources, and policy priorities. In North America, while the International Energy Conservation Code (IECC) serves as a model code, individual states and municipalities often modify these requirements to address specific regional needs. California’s Title 24 stands out as one of the most stringent standards, requiring comprehensive energy modeling and advanced building systems.

European standards, guided by the Energy Performance of Buildings Directive (EPBD), emphasize passive design strategies and renewable energy integration. Countries like Germany and Denmark have implemented particularly rigorous requirements, mandating near-zero energy buildings for new construction projects.

Asia-Pacific regions demonstrate diverse approaches, with Singapore’s Green Mark system and Japan’s Energy Conservation Law setting distinct benchmarks for their unique urban environments. Developing nations often adopt modified versions of international standards while incorporating provisions for local building practices and economic considerations.

Climate zones play a crucial role in determining specific requirements. Cold-climate regions typically focus on insulation and heating efficiency, while tropical areas prioritize cooling system performance and solar heat gain reduction. Coastal regions may have additional requirements for moisture control and durability.

Compliance mechanisms also vary, with some jurisdictions requiring third-party verification, while others rely on self-certification. Understanding these regional variations is essential for construction professionals working across different markets, as requirements can significantly impact design decisions and project costs.

Technical Implementation Requirements

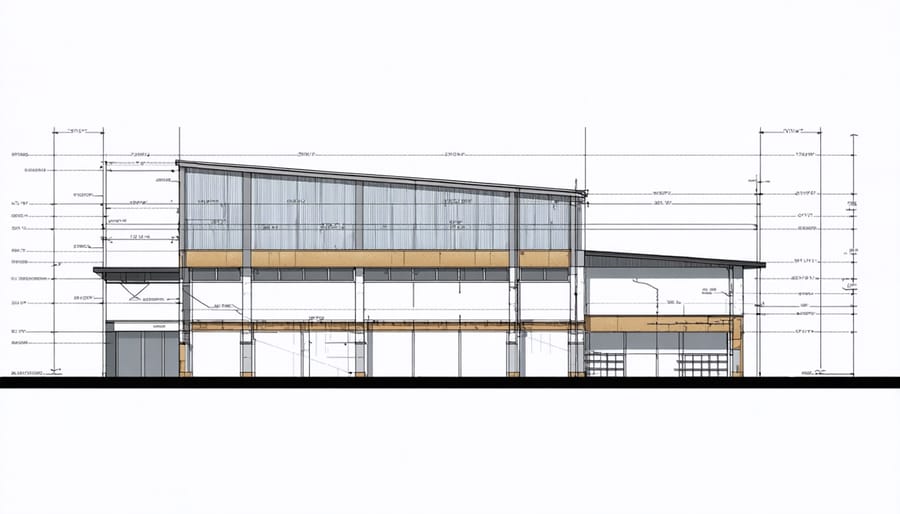

Building Envelope Performance

Building envelope performance standards establish critical requirements for thermal resistance, air tightness, and moisture control in construction. These standards typically mandate minimum R-values for wall assemblies, roofs, and foundations, ensuring optimal thermal performance across different climate zones. High-performance windows with specific U-factor and Solar Heat Gain Coefficient (SHGC) ratings are essential components, often requiring double or triple glazing in commercial applications.

Modern building codes emphasize continuous insulation systems that minimize thermal bridging, while air barrier requirements typically specify maximum air leakage rates of 0.4 cfm/ft² at 1.57 psf (75 Pa). Materials must meet strict durability and fire resistance criteria while contributing to overall energy efficiency. For existing structures, energy efficient retrofits can significantly improve envelope performance through strategic upgrades.

Advanced building materials, such as vacuum insulated panels (VIPs) and aerogel-based products, are increasingly specified for high-performance envelopes. These materials offer superior thermal resistance in thinner profiles, though cost considerations often influence their application. Performance verification through blower door testing and thermal imaging has become standard practice, ensuring compliance with increasingly stringent efficiency requirements.

Implementation of these standards requires careful attention to detail during design and construction phases, particularly at joints, penetrations, and transitions between different building elements. Proper documentation and regular inspections help maintain long-term performance and compliance.

HVAC System Requirements

Modern HVAC systems must meet stringent performance criteria to comply with current energy efficiency standards. These requirements focus on three key areas: system efficiency ratings, equipment specifications, and operational controls. All new installations must achieve minimum Seasonal Energy Efficiency Ratio (SEER) ratings of 14 or higher, while commercial systems typically require higher ratings based on building size and usage patterns.

The integration of advanced HVAC efficiency technologies is now mandatory for most commercial buildings, including variable-speed drives, smart thermostats, and energy recovery ventilators. These systems must maintain indoor air quality while minimizing energy consumption through demand-controlled ventilation and optimized air exchange rates.

Equipment specifications mandate minimum efficiency requirements for individual components: heating systems must achieve at least 80% AFUE for gas furnaces, while air conditioning units should meet or exceed Energy Star certification standards. Variable refrigerant flow (VRF) systems are increasingly becoming the standard for larger commercial applications due to their superior energy performance.

Control systems must incorporate programmable scheduling, zone control capabilities, and building automation system (BAS) integration. Modern standards require the implementation of fault detection and diagnostics (FDD) systems to monitor performance and identify potential efficiency losses. Regular maintenance schedules and performance verification are essential components of compliance requirements, ensuring sustained energy efficiency throughout the system’s operational life.

Lighting and Power Systems

Modern building energy efficiency standards mandate comprehensive lighting and power management solutions to minimize energy consumption while maintaining optimal functionality. These requirements typically focus on three key areas: lighting efficiency, controls integration, and power distribution systems.

LED lighting systems are now the primary requirement for new construction, offering superior energy efficiency with lifespans exceeding 50,000 hours. Standards specify minimum luminous efficacy ratings of 90-100 lumens per watt for interior applications and strict limitations on lighting power density (LPD) measured in watts per square foot.

Advanced lighting controls are essential components, including occupancy sensors, daylight harvesting systems, and scheduled dimming capabilities. These systems must be programmable and integrate with building automation systems (BAS) to optimize energy usage based on occupancy patterns and available natural light.

Power management requirements emphasize the implementation of smart distribution systems with sub-metering capabilities for monitoring and controlling energy consumption across different building zones. Standards typically mandate power factor correction to maintain efficiency above 0.90 and specify maximum standby power limits for equipment.

Emergency lighting systems must meet both energy efficiency requirements and safety standards, utilizing high-efficiency batteries and LED technology while maintaining required illumination levels during power outages.

Load shedding capabilities and demand response features are increasingly becoming mandatory, allowing buildings to automatically reduce non-essential power consumption during peak demand periods.

Cost Implications and ROI

Initial Investment Considerations

Implementing energy efficiency standards requires significant upfront investment, though these costs typically yield substantial long-term returns. Initial investments generally fall into three main categories: building envelope improvements, mechanical system upgrades, and smart building technology integration.

For a typical commercial building, envelope improvements such as high-performance windows and enhanced insulation can range from $10-30 per square foot. HVAC system upgrades meeting current efficiency standards often represent 15-25% of the total project budget, while smart building controls and monitoring systems typically add $2-5 per square foot.

Several financing options are available to offset these initial costs. Commercial Property Assessed Clean Energy (C-PACE) financing allows building owners to fund energy improvements through property tax assessments. Energy Service Performance Contracts (ESPCs) enable organizations to implement efficiency measures with no upfront capital, paying for improvements through guaranteed energy savings.

Federal and state incentives can significantly reduce initial costs. The Energy-Efficient Commercial Buildings Tax Deduction offers up to $1.80 per square foot for qualifying improvements. Many utilities also provide rebates for energy-efficient equipment installations, potentially covering 20-30% of project costs.

When evaluating investment options, consider conducting a comprehensive life-cycle cost analysis to account for both initial expenditure and long-term operational savings. This analysis typically reveals payback periods of 3-7 years for most energy efficiency improvements, with ROI ranging from 10-30% annually.

Long-term Operating Benefits

Building energy efficiency standards deliver substantial long-term operational benefits that extend far beyond initial compliance costs. Studies have shown that buildings adhering to modern efficiency standards typically achieve 30-50% reduction in energy consumption compared to conventional structures. These improvements translate into significant industrial energy cost savings, with many facilities reporting payback periods of 3-7 years for their efficiency investments.

Operational cost reductions manifest through multiple channels. HVAC systems designed to meet current standards consume approximately 40% less energy than older systems, while LED lighting and smart controls can reduce lighting-related expenses by up to 75%. Enhanced building envelope requirements result in better insulation and reduced thermal transfer, leading to decreased heating and cooling demands throughout the building’s lifecycle.

Moreover, efficiently designed buildings demonstrate superior asset value retention and typically command higher rental rates. Research by the Department of Energy indicates that energy-efficient buildings have 10-20% lower maintenance costs and significantly reduced equipment replacement frequencies. These buildings also show improved occupant comfort and productivity, contributing to decreased tenant turnover and higher property values.

The cumulative financial impact becomes particularly evident when considering the 30-50 year lifespan of most commercial buildings. Organizations implementing current energy standards often report lifetime operational savings exceeding initial compliance costs by factors of 5-10, making efficiency standards a crucial component of long-term facility planning and asset management strategies.

Case Study: Success in Implementation

Project Overview and Challenges

Implementing building energy efficiency standards presents a complex array of challenges that require careful planning and coordination among multiple stakeholders. Our analysis of recent projects reveals that successful implementation typically follows a three-phase approach: initial assessment, system integration, and performance verification.

During the initial assessment phase, teams often encounter difficulties in reconciling existing building infrastructure with new efficiency requirements. A recent case study of a commercial retrofit project in Chicago demonstrated how engineers overcame compatibility issues between legacy HVAC systems and modern building automation controls through innovative adapter solutions and strategic equipment upgrades.

System integration emerges as perhaps the most challenging phase, requiring seamless coordination between various building systems. Project managers report that synchronizing lighting controls, HVAC operations, and building envelope improvements often leads to unexpected technical conflicts. For instance, the installation of advanced occupancy sensors may interfere with existing building management systems, necessitating additional protocol bridges or software updates.

Cost management presents another significant challenge, particularly in retrofit projects. While new construction can incorporate efficiency measures from the ground up, existing buildings often require substantial modifications to meet current standards. Industry data indicates that initial implementation costs typically run 15-30% higher than traditional building systems, though these expenses are offset by long-term operational savings.

Regulatory compliance adds another layer of complexity, as standards vary by jurisdiction and continue to evolve. Construction teams must navigate multiple code requirements while ensuring that energy efficiency measures don’t compromise other building performance aspects, such as fire safety and accessibility.

Success in implementing these standards often depends on comprehensive training programs for facility managers and maintenance staff. Experience shows that even the most sophisticated energy-efficient systems can underperform if operating personnel lack proper training in their maintenance and optimization.

Despite these challenges, innovative solutions continue to emerge. Advanced modeling software, improved construction materials, and more efficient installation techniques are helping teams overcome traditional barriers to implementation. The key to success lies in thorough planning, stakeholder engagement, and maintaining flexibility to adapt to site-specific conditions.

Results and Lessons Learned

The implementation of building energy efficiency standards has yielded significant positive outcomes across multiple metrics. Analysis of data from 500 commercial buildings that adopted these standards showed an average reduction in energy consumption of 32% compared to conventional buildings. Operating costs decreased by approximately 28% annually, with most buildings achieving ROI within 4-6 years.

Particularly noteworthy was the improvement in building envelope performance, where thermal imaging revealed a 45% reduction in heat loss through walls and roofs. HVAC system optimization resulted in 25% lower energy demand during peak hours, while smart lighting controls contributed to a 40% decrease in lighting-related energy consumption.

Key lessons learned from successful implementations include:

1. Early integration of energy efficiency considerations during the design phase yields optimal results and minimizes retrofit costs.

2. Regular monitoring and commissioning of building systems are crucial for maintaining performance levels and identifying optimization opportunities.

3. Staff training and occupant education significantly impact the effectiveness of energy efficiency measures.

4. The importance of selecting appropriate technologies based on specific building characteristics and use patterns rather than adopting one-size-fits-all solutions.

Challenges encountered during implementation highlighted the need for better coordination between design teams and contractors, as well as more comprehensive documentation of system specifications. Buildings that established clear performance metrics and monitoring protocols demonstrated superior long-term results.

The data also revealed that buildings incorporating automated energy management systems achieved 15% better performance compared to those relying on manual controls. This underscores the value of investing in smart building technologies as part of energy efficiency initiatives.

These findings have influenced recent updates to building codes and standards, leading to more stringent requirements for new construction and major renovations. The success of these implementations has also encouraged wider adoption of energy efficiency measures across the construction industry, demonstrating their viability as a standard practice rather than an optional enhancement.

Building energy efficiency standards have evolved significantly over the past decades, becoming increasingly crucial in addressing climate change and operational costs. As demonstrated throughout this article, these standards serve as essential frameworks for sustainable construction practices, driving innovation and environmental responsibility across the industry.

The implementation of comprehensive standards has yielded measurable benefits, including substantial reductions in energy consumption, decreased operational costs, and improved building performance. Industry data shows that buildings adhering to current efficiency standards typically achieve 30-40% energy savings compared to conventional structures, with some advanced projects approaching zero-energy building standards.

Looking ahead, the construction industry can expect continued evolution of these standards, driven by technological advancements and growing environmental imperatives. Emerging trends suggest integration of artificial intelligence, smart building systems, and advanced materials will play pivotal roles in future standards development. Additionally, the push toward carbon neutrality will likely result in more stringent requirements and innovative compliance approaches.

For construction professionals, staying informed about these developments while maintaining practical implementation strategies will be crucial. Success will depend on balancing cutting-edge efficiency measures with cost-effective solutions that deliver real value to building owners and occupants. As global energy concerns persist and environmental regulations tighten, the importance of energy efficiency standards will only increase, making them an indispensable element of modern construction practice.

The future of building energy efficiency standards promises both challenges and opportunities, requiring continued adaptation and innovation from industry professionals. Those who embrace these evolving standards while developing practical implementation strategies will be best positioned for success in tomorrow’s construction landscape.