Sustainability Life Cycle Analysis (LCA) revolutionizes modern construction by quantifying environmental impacts across a building’s entire existence – from material extraction through demolition. As construction professionals increasingly adopt decarbonization strategies, LCA emerges as the definitive framework for measuring and optimizing project sustainability.

This comprehensive methodology enables project teams to evaluate embodied carbon, operational emissions, and end-of-life environmental costs with unprecedented precision. By analyzing each phase – from manufacturing and transportation to construction, operation, and eventual demolition – LCA reveals optimization opportunities that traditional assessment methods often miss.

Recent advancements in LCA software and building information modeling (BIM) integration now allow construction professionals to conduct real-time analyses during design development, enabling data-driven decisions that significantly reduce environmental impact while maintaining project feasibility and cost-effectiveness. This systematic approach has become indispensable for meeting increasingly stringent environmental regulations and achieving ambitious sustainability certifications.

For construction industry leaders seeking to future-proof their projects and demonstrate environmental leadership, mastering LCA implementation is no longer optional – it’s a strategic imperative that delivers measurable value throughout the building lifecycle while ensuring compliance with evolving sustainability standards.

Understanding Lifecycle Carbon Analysis in Construction

Key Components of Construction LCA

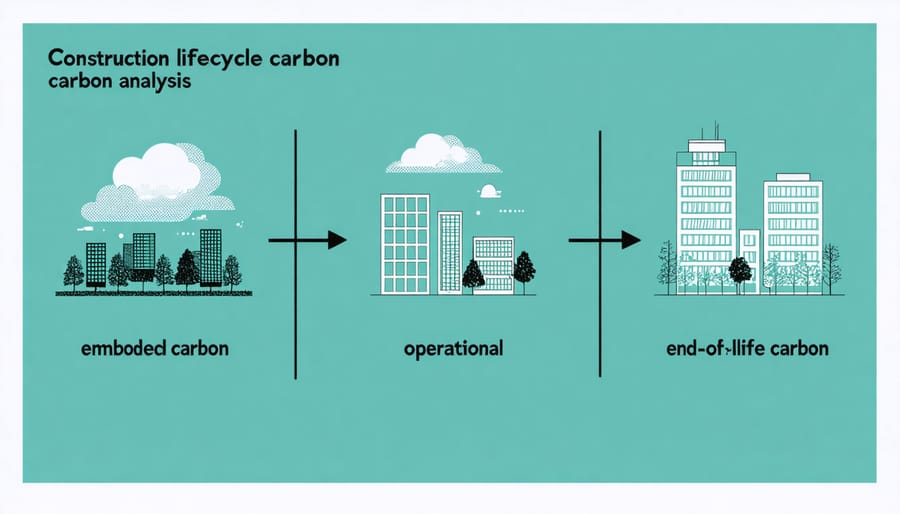

Construction lifecycle analysis encompasses three critical carbon components that shape a project’s environmental impact. The first is embodied carbon, which accounts for emissions associated with material extraction, manufacturing, transportation, and construction processes. Implementing effective embodied carbon reduction strategies during the design and material selection phases can significantly decrease a building’s initial carbon footprint.

Operational carbon, the second component, represents emissions generated during the building’s service life through heating, cooling, lighting, and other building systems. This typically accounts for the largest portion of a building’s lifetime carbon emissions, often ranging from 60-90% of total emissions in traditional buildings. Modern design approaches and energy-efficient systems can substantially reduce these operational impacts.

End-of-life carbon, the final component, encompasses emissions related to building demolition, waste processing, and material disposal or recycling. This aspect is increasingly important as the construction industry moves toward circular economy principles. Careful consideration of deconstruction strategies and material recyclability during the design phase can minimize end-of-life carbon impacts.

Understanding these components enables project teams to make informed decisions that optimize carbon performance across the entire building lifecycle, from initial design through eventual demolition or repurposing.

Industry Standards and Methodologies

Several internationally recognized standards and methodologies guide the implementation of sustainability life cycle analysis in construction projects. The ISO 14040 and 14044 standards form the foundational framework, establishing principles, requirements, and guidelines for conducting LCA studies. These standards ensure consistency and reliability in assessment methods across the industry.

The European Committee for Standardization’s EN 15978 specifically addresses the assessment of environmental performance in buildings, providing detailed calculation methods for evaluating impacts throughout a building’s lifecycle. This standard works in conjunction with EN 15804, which focuses on Environmental Product Declarations (EPDs) for construction materials.

Leading assessment tools include SimaPro, GaBi, and OpenLCA, which offer comprehensive databases and calculation capabilities for conducting detailed LCA studies. The Building Research Establishment Environmental Assessment Method (BREEAM) and Leadership in Energy and Environmental Design (LEED) incorporate LCA principles into their certification frameworks, encouraging wider adoption of lifecycle thinking in construction.

Industry practitioners also rely on the Level(s) framework, developed by the European Commission, which provides a common language for assessing and reporting building sustainability performance. This framework integrates well with existing assessment schemes while focusing on circular economy principles and whole-life carbon assessment.

For material-specific assessments, Environmental Product Declarations (EPDs) following ISO 14025 provide standardized, verified information about the environmental impact of construction products, enabling informed decision-making in material selection and specification.

Implementation Process

Data Collection and Analysis

The collection and analysis of carbon data throughout construction phases requires a systematic approach combining multiple data sources and sophisticated analytical methods. Primary data collection involves direct measurements of energy consumption, material quantities, and emissions using specialized monitoring equipment and smart sensors. This is supplemented by secondary data from Environmental Product Declarations (EPDs), industry databases, and supplier documentation.

Key measurement points include embodied carbon in materials during procurement, operational emissions during construction activities, and transportation-related carbon footprint. Advanced Building Information Modeling (BIM) systems integrate with carbon calculators to provide real-time analysis of environmental impacts across different construction stages.

Data analysis typically follows a three-step process: data validation, normalization, and interpretation. Validation ensures accuracy through cross-referencing multiple data sources and removing anomalies. Normalization adjusts measurements to account for project scale, regional factors, and seasonal variations. The interpretation phase employs statistical analysis tools to identify patterns, trends, and opportunities for carbon reduction.

Modern construction projects increasingly utilize cloud-based platforms that enable continuous monitoring and reporting of carbon metrics. These systems often feature dashboard interfaces that present real-time analytics, allowing project managers to make informed decisions about sustainability measures. Regular benchmarking against industry standards and similar projects helps establish meaningful context for the collected data and supports evidence-based optimization strategies.

Tools and Technologies

Several sophisticated software platforms and technologies are available to support sustainability life cycle analysis in construction projects. Leading solutions include Tally, One Click LCA, and Athena Impact Estimator, which offer comprehensive carbon tracking capabilities throughout project phases. These tools integrate seamlessly with Building Information Modeling (BIM) systems, enabling real-time environmental impact assessments during design and construction.

Modern AI-powered analytics tools have significantly enhanced the accuracy and efficiency of lifecycle analysis, providing automated data collection and predictive modeling capabilities. These systems can process vast amounts of environmental product declarations (EPDs) and material data to generate detailed carbon footprint reports.

Cloud-based platforms like EC3 (Embodied Carbon in Construction Calculator) have revolutionized how teams collaborate on sustainability metrics, offering centralized databases for material environmental impacts and standardized reporting frameworks. Integration capabilities with project management software ensure that sustainability data flows seamlessly between different stakeholders.

For on-site monitoring, IoT sensors and smart meters provide real-time data on energy consumption, water usage, and waste management. These technologies, combined with advanced analytics platforms, enable construction teams to make data-driven decisions that optimize resource efficiency and reduce environmental impact throughout the building’s lifecycle.

Reporting and Documentation

Effective reporting and documentation are crucial components of sustainability lifecycle analysis in construction projects. The reporting process should follow a structured approach that captures both quantitative data and qualitative assessments throughout the project lifecycle.

Begin by establishing a clear baseline documentation that includes initial carbon calculations, material specifications, and energy consumption projections. This foundational data serves as a reference point for subsequent comparisons and validates the effectiveness of sustainable strategies implemented during construction.

Reports should detail the methodology used for calculations, including any assumptions made and standards followed (such as ISO 14040 or EN 15978). Include comprehensive data on embodied carbon in materials, operational carbon emissions, and end-of-life considerations. Present this information using standardized metrics and units to ensure consistency and comparability across different project phases.

Document all sustainable design decisions, material substitutions, and optimization strategies, along with their corresponding impact on carbon reduction. Utilize visual representations such as graphs, charts, and comparison tables to effectively communicate complex data to stakeholders.

Maintain a living document that tracks progress against sustainability targets, highlighting both achievements and areas requiring attention. Include regular updates on actual performance metrics compared to initial projections, and document any corrective actions taken to address deviations.

Finally, ensure all documentation is digitally archived and easily accessible for future reference, audits, and certification purposes. This creates a valuable knowledge base for future projects and demonstrates commitment to transparency in sustainable construction practices.

Case Study: Real-World Application

The One World Trade Center project in New York City stands as a prime example of successful LCA implementation in modern construction. This 104-story skyscraper, completed in 2014, incorporated comprehensive lifecycle analysis throughout its development phases, yielding remarkable environmental and economic benefits.

The project team initiated LCA during the early design phase, analyzing multiple scenarios for structural systems, façade materials, and mechanical systems. Using specialized LCA software, they evaluated the environmental impacts of various construction materials, including concrete mixes, steel compositions, and glazing systems. This analysis extended beyond immediate construction impacts to consider operational energy consumption, maintenance requirements, and end-of-life scenarios over a 60-year building lifespan.

Key findings from the analysis led to several crucial design decisions. The team opted for concrete containing 20% recycled content, reducing embodied carbon by approximately 25% compared to conventional mixes. The building’s curtain wall system, featuring high-performance glass and aluminum frames with recycled content, was selected based on its superior lifecycle performance despite higher initial costs.

The mechanical systems selection process particularly benefited from LCA insights. The team chose a hybrid system combining natural ventilation with high-efficiency HVAC equipment, projected to reduce operational energy consumption by 30% compared to baseline scenarios. Water management systems were designed to reduce consumption by 40% through greywater recycling and rainwater harvesting.

Quantifiable results from this implementation include:

– 32% reduction in overall embodied carbon

– 41% decrease in operational energy costs

– 35% reduction in water consumption

– 25% lower maintenance costs over the building’s projected lifespan

The project team overcame several challenges, including initial stakeholder resistance to higher upfront costs and coordination complexities among multiple contractors. Regular stakeholder meetings and clear communication of lifecycle benefits helped maintain alignment with sustainability goals. The team also developed a custom tracking system to monitor actual performance against LCA projections during construction and early operation phases.

This case demonstrates how thorough lifecycle analysis can inform decision-making at every project stage, leading to significant environmental and economic benefits. The success has influenced subsequent projects in the region, establishing new benchmarks for sustainable high-rise construction.

Challenges and Solutions

Data Accuracy and Availability

Data accuracy and availability present significant challenges in conducting comprehensive sustainability life cycle analyses in construction projects. The quality of results heavily depends on the completeness and reliability of input data across multiple project phases and material supply chains.

Industry professionals often face difficulties in obtaining detailed environmental impact data from manufacturers, particularly for innovative or locally sourced materials. This challenge is compounded by inconsistencies in data reporting methods and varying regional standards for environmental impact measurements.

To ensure reliable analyses, practitioners should implement rigorous data verification protocols and maintain detailed documentation of data sources. Regular updates to material databases and environmental product declarations (EPDs) are essential, as environmental impact factors can change with manufacturing processes and energy sources.

Best practices include:

– Establishing partnerships with trusted material suppliers who provide verified environmental data

– Using standardized data collection templates across project stakeholders

– Implementing digital tools for automated data gathering and verification

– Conducting regular audits of data quality and completeness

– Maintaining transparent documentation of data assumptions and limitations

When faced with data gaps, professionals should apply conservative estimates based on industry benchmarks while clearly documenting these assumptions in final reports.

Cost and Resource Considerations

Implementing a comprehensive sustainability life cycle analysis requires careful consideration of both direct and indirect costs. Initial investments typically include specialized software licenses, training programs for staff, and potentially hiring dedicated sustainability consultants. For medium to large construction firms, these startup costs generally range from $50,000 to $150,000, depending on project scope and complexity.

Ongoing operational costs involve data collection systems, regular software updates, and continuous professional development. Organizations should allocate resources for dedicated personnel to manage LCA processes, with larger projects potentially requiring a full-time sustainability coordinator. Annual maintenance costs typically represent 15-25% of initial implementation expenses.

Resource allocation must account for both human capital and technological infrastructure. Key considerations include:

– Staff training and certification programs

– Data collection and management systems

– External consultancy services when needed

– Quality assurance and verification processes

– Regular reporting and documentation requirements

To optimize cost-effectiveness, organizations should develop a phased implementation strategy, starting with pilot projects before full-scale deployment. This approach allows for better resource management and helps identify potential efficiency improvements early in the process. Many firms find that the initial investment is offset by long-term cost savings through improved resource efficiency and enhanced project outcomes.

Future Trends and Implications

The future of sustainability lifecycle analysis in construction is rapidly evolving, driven by technological advancements and increasing environmental pressures. Digital twin technology is emerging as a game-changer, enabling real-time monitoring and optimization of building performance throughout its lifecycle. These virtual replicas allow stakeholders to simulate different scenarios and make data-driven decisions that enhance sustainability outcomes.

Artificial Intelligence and Machine Learning are revolutionizing how we collect and analyze lifecycle data. These technologies can process vast amounts of information to identify patterns, predict environmental impacts, and suggest optimization strategies with unprecedented accuracy. The integration of IoT sensors and smart building systems is also enabling more precise measurement of operational impacts, leading to better-informed decisions during both design and operation phases.

The adoption of circular economy principles is expected to become increasingly central to LCA methodologies. This shift will emphasize material reuse, waste reduction, and design for deconstruction, fundamentally changing how we approach building lifecycle assessment.

Standardization of LCA practices is another significant trend, with international bodies working to develop more unified frameworks and metrics. This standardization will facilitate better comparison between projects and enable more effective benchmarking across the industry. Additionally, the rise of blockchain technology promises to enhance supply chain transparency and material tracking, providing more accurate lifecycle data.

Looking ahead, we can expect to see greater integration of social and economic factors into LCA methodologies, moving beyond purely environmental considerations. This holistic approach will better reflect the true sustainability impact of construction projects. The increasing focus on embodied carbon reduction targets will also drive innovation in LCA tools and methodologies, particularly in the early design stages where the most significant impact reductions can be achieved.

Sustainability lifecycle analysis has emerged as a crucial tool for construction professionals seeking to create more environmentally responsible buildings and infrastructure. Through careful consideration of material selection, energy consumption, waste management, and operational efficiency, construction teams can significantly reduce their projects’ environmental impact while often achieving cost savings over the full lifecycle of the structure.

To effectively implement lifecycle analysis in construction projects, professionals should focus on three key areas: early integration into the design phase, comprehensive data collection throughout the construction process, and ongoing monitoring during the operational phase. The most successful projects demonstrate that decisions made during initial planning stages have the greatest potential for positive environmental and economic impact.

Construction professionals can take immediate action by establishing standardized procedures for data collection, investing in lifecycle analysis software tools, and training team members in sustainability assessment methods. It’s essential to engage all stakeholders early in the process and maintain clear communication about sustainability goals and metrics throughout the project lifecycle.

Looking ahead, the industry’s adoption of sustainability lifecycle analysis will continue to grow as regulatory requirements tighten and client demands evolve. Professionals who develop expertise in this area will be better positioned to deliver projects that meet both environmental standards and client expectations while maintaining competitive advantages in the market.

Success in implementing lifecycle analysis requires commitment, collaboration, and continuous learning. By embracing these principles and incorporating them into standard project management practices, construction professionals can lead the industry toward a more sustainable future.