Revolutionizing industrial energy efficiency demands strategic implementation of smart building technologies alongside proven optimization methods. Industrial facilities consume approximately 30% of global energy resources, yet systematic efficiency improvements can reduce operational costs by 20-30% while maintaining production output. Modern manufacturing facilities have demonstrated that combining advanced monitoring systems, process optimization, and strategic equipment upgrades delivers substantial returns on investment within 24-36 months.

Leading manufacturers are achieving unprecedented energy savings through real-time consumption monitoring, predictive maintenance protocols, and intelligent automation systems. These solutions, when properly integrated, create a comprehensive energy management framework that addresses the three primary areas of industrial energy waste: equipment inefficiency, process optimization gaps, and operational behavioral patterns.

The transformation toward energy-efficient industrial operations represents more than just cost savings—it’s becoming a critical factor in maintaining competitive advantage and meeting increasingly stringent environmental regulations. Forward-thinking facility managers who implement strategic energy management programs consistently report improved operational reliability, reduced maintenance costs, and enhanced production quality alongside significant energy savings.

Advanced Building Envelope Technologies

High-Performance Insulation Systems

Modern industrial insulation systems have evolved significantly, offering unprecedented thermal performance and energy savings. Advanced multilayer insulation materials, incorporating aerogels and vacuum-insulated panels (VIPs), achieve R-values up to five times higher than traditional materials while requiring less thickness.

Leading manufacturers now produce composite insulation systems that combine different materials to optimize performance across varying temperature ranges and operating conditions. These systems typically feature a core layer of high-performance material surrounded by protective outer layers that enhance durability and moisture resistance.

Installation techniques have also advanced, with precision-fitting methods and innovative joining systems minimizing thermal bridges. Computer-aided thermal imaging during installation ensures complete coverage and identifies potential weak points before they become problematic.

Recent case studies demonstrate impressive results. A chemical processing facility in Germany reduced its energy consumption by 35% after upgrading to a modern aerogel-based insulation system. Similarly, a food processing plant in Canada achieved annual energy savings of $175,000 by implementing VIP insulation on their steam distribution network.

Key considerations for selecting high-performance insulation include:

– Operating temperature range requirements

– Exposure to moisture or chemicals

– Space constraints

– Long-term cost-benefit analysis

– Installation and maintenance accessibility

Regular maintenance and monitoring of these systems is crucial for maintaining optimal performance. Modern sensor systems can provide real-time data on insulation effectiveness, allowing for proactive maintenance and optimization of energy efficiency.

Smart Fenestration Solutions

Smart fenestration solutions play a crucial role in optimizing industrial energy efficiency by managing natural light and thermal transfer. Advanced glazing technologies, such as low-emissivity (low-e) glass and dynamic electrochromic windows, can reduce HVAC loads by up to 30% while maintaining comfortable indoor temperatures.

Modern industrial facilities benefit from strategic window placement and sizing, utilizing daylighting analysis tools to maximize natural light penetration while minimizing heat gain. Double-pane or triple-pane windows with inert gas fills, such as argon or krypton, provide superior insulation compared to traditional single-pane options, achieving U-values as low as 0.15.

Industrial doors also contribute significantly to energy efficiency. High-speed roll-up doors with advanced sealing systems minimize air infiltration in high-traffic areas, while thermal break technology in personnel doors prevents heat transfer through metal frames. Loading dock solutions incorporating air curtains and dock seals can reduce energy losses during material handling operations.

Light shelves and solar tubes represent innovative daylighting strategies that redirect natural light deep into building interiors, reducing dependency on artificial lighting. When combined with automated lighting controls and occupancy sensors, these solutions can decrease lighting energy consumption by up to 40%.

Implementation of smart fenestration systems should be integrated with building automation systems (BAS) to optimize performance based on real-time environmental conditions and occupancy patterns, ensuring maximum energy efficiency while maintaining operational functionality.

Intelligent HVAC Optimization

AI-Driven Climate Control

Artificial Intelligence is revolutionizing industrial climate control systems, offering unprecedented levels of efficiency and cost savings. By implementing modern HVAC optimization techniques, facilities can reduce energy consumption by 20-30% while maintaining optimal comfort conditions.

Smart HVAC management systems utilize machine learning algorithms to analyze multiple data points, including occupancy patterns, weather forecasts, thermal loads, and equipment performance metrics. These systems continuously adjust temperature, humidity, and airflow parameters in real-time, ensuring optimal energy usage while meeting specific industrial requirements.

Recent case studies demonstrate the effectiveness of AI-driven climate control. A manufacturing facility in Detroit implemented predictive maintenance algorithms and smart zoning, resulting in a 25% reduction in HVAC-related energy costs within the first year. The system’s ability to anticipate equipment failures and optimize maintenance schedules contributed to an additional 15% decrease in operational expenses.

Key features of advanced AI climate control systems include:

– Predictive analytics for equipment maintenance

– Dynamic load balancing

– Automated fault detection and diagnostics

– Real-time energy consumption monitoring

– Integration with building management systems

Industrial facilities can maximize the benefits of AI-driven climate control by establishing clear implementation protocols, training facility managers, and regularly updating system parameters based on performance data. The initial investment typically yields returns within 18-24 months through reduced energy consumption, lower maintenance costs, and improved equipment longevity.

Heat Recovery Systems

Heat recovery systems represent a significant opportunity for industrial facilities to capture and repurpose waste heat, dramatically improving overall energy efficiency. These systems can recover thermal energy from various sources, including exhaust gases, cooling water, and process waste streams, converting what would otherwise be lost energy into useful heat for other applications.

A well-designed heat recovery system typically consists of heat exchangers, thermal storage units, and distribution networks. Common applications include preheating combustion air, generating steam for process use, space heating, and even power generation through waste heat recovery boilers.

According to industry studies, heat recovery systems can reclaim 50-90% of waste heat, depending on the application and technology used. For example, a metal manufacturing plant in Germany implemented a comprehensive heat recovery system that reduced their energy consumption by 35% and achieved a return on investment within two years.

Key technologies in modern heat recovery systems include:

– Plate heat exchangers for liquid-to-liquid heat transfer

– Economizers for recovering heat from boiler exhaust

– Regenerative heat exchangers for high-temperature applications

– Heat pipes for efficient thermal transfer in confined spaces

When implementing heat recovery systems, it’s crucial to consider factors such as temperature differences between heat source and sink, distance between recovery and use points, and potential contamination issues. Regular maintenance and monitoring ensure optimal performance and longevity of these systems.

For maximum efficiency, heat recovery should be integrated into the facility’s overall energy management strategy, with careful consideration of seasonal variations in heat availability and demand. This systematic approach ensures the most cost-effective use of recovered thermal energy throughout the year.

Industrial Lighting Solutions

LED Implementation Strategies

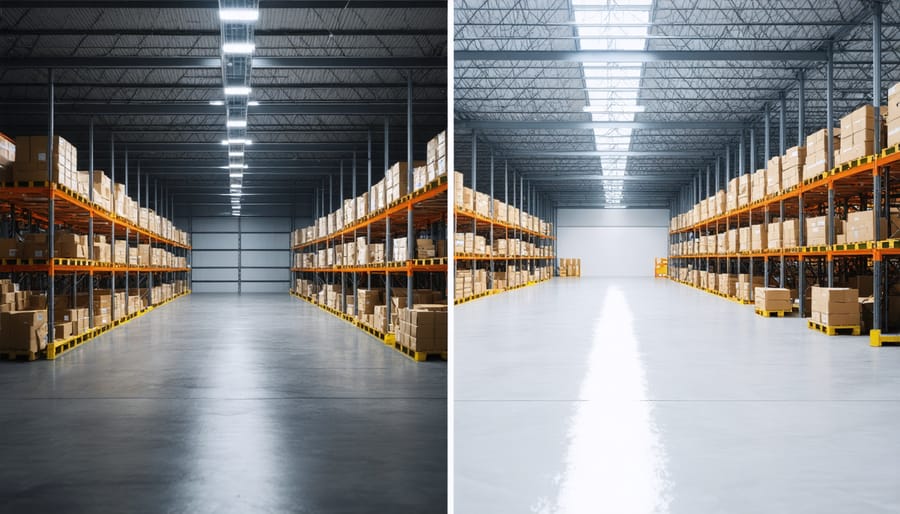

Modern LED lighting systems represent a significant opportunity for industrial energy savings, offering up to 75% reduction in lighting-related energy consumption compared to traditional lighting solutions. Advanced LED fixtures now deliver superior illumination while consuming substantially less power, making them an essential component of energy-efficient industrial operations.

Implementing smart LED systems with integrated controls maximizes energy savings through features like occupancy sensing, daylight harvesting, and automated dimming. These systems can adjust light levels based on natural light availability and operational requirements, ensuring optimal illumination while minimizing waste. Industry leaders report additional 25-35% energy savings when combining LEDs with intelligent controls.

Strategic zoning and task-appropriate lighting levels further enhance efficiency. High-bay LED fixtures in warehouses can be programmed to operate at different intensities based on specific work areas and times of day. Manufacturing floors benefit from targeted lighting solutions that concentrate illumination where needed while maintaining lower ambient light levels elsewhere.

Modern LED systems also offer extended lifespans of 50,000+ hours, reducing maintenance costs and replacement frequency. The initial investment in LED technology typically achieves ROI within 2-3 years through reduced energy consumption and maintenance requirements. Case studies from major manufacturing facilities demonstrate that comprehensive LED retrofits, combined with smart controls, can deliver annual energy savings of $0.50-$1.00 per square foot while improving workplace safety and productivity.

Daylight Harvesting Systems

Daylight harvesting systems represent a sophisticated approach to energy efficiency in industrial facilities by maximizing the use of natural light while optimizing artificial lighting consumption. These systems utilize photosensors and automated controls to adjust artificial lighting levels based on available daylight, potentially reducing lighting energy costs by 20-60%.

Key components of an effective daylight harvesting system include strategically placed skylights, light tubes, and clerestory windows, combined with photoelectric sensors and dimming controls. Modern systems can be integrated with building automation systems (BAS) for seamless operation and enhanced energy management.

Implementation requires careful consideration of facility layout, production requirements, and local climate conditions. Optimal results are achieved through proper positioning of workstations relative to natural light sources and strategic zoning of lighting controls. For example, a manufacturing facility in Arizona reported a 45% reduction in lighting energy costs after installing a comprehensive daylight harvesting system with automated controls.

To maximize system efficiency, regular maintenance of both natural and artificial lighting components is essential. This includes cleaning skylights and sensors, calibrating control systems, and ensuring proper integration with other building systems. Additionally, employee training on system operation and benefits helps ensure successful adoption and optimal performance.

Return on investment typically ranges from 2-5 years, depending on facility size, existing infrastructure, and local utility rates. The benefits extend beyond energy savings to include improved worker productivity and reduced HVAC loads due to decreased heat generation from artificial lighting.

Renewable Energy Integration

Solar Power Solutions

Implementing solar power solutions in industrial facilities represents a significant opportunity for sustainable energy management and cost reduction. Modern industrial solar implementation strategies have evolved to address the unique demands of manufacturing and processing facilities.

Rooftop solar installations remain the most common approach, utilizing expansive industrial roof areas for photovoltaic (PV) arrays. These systems can be optimized through smart positioning and advanced tracking mechanisms that maximize solar exposure throughout the day. For facilities with limited roof space, ground-mounted arrays and solar carports offer viable alternatives, providing additional benefits such as weather protection for vehicles and equipment.

Energy storage integration has become crucial for industrial solar systems, enabling facilities to maintain consistent power supply during peak demand periods. Advanced battery systems, coupled with sophisticated energy management software, help optimize power distribution and reduce reliance on grid electricity during high-rate periods.

Recent technological advances have introduced bifacial solar panels, which capture reflected light on both sides, increasing energy yield by up to 30% compared to traditional panels. Additionally, thin-film solar technologies offer flexibility in installation, allowing for integration on curved surfaces and vertical walls.

To maximize ROI, industries should consider implementing hybrid systems that combine solar power with other renewable sources, such as wind or biomass, creating a more resilient and efficient energy infrastructure. Regular maintenance protocols and performance monitoring systems ensure optimal system efficiency and longevity.

Energy Storage Systems

Modern industrial facilities can significantly enhance their energy efficiency through advanced energy storage solutions. Battery storage systems, particularly lithium-ion installations, enable facilities to store excess energy during off-peak periods and utilize it during high-demand times, effectively reducing peak load charges and optimizing energy consumption patterns.

Thermal energy storage (TES) systems represent another crucial component in industrial energy management. These systems can store heat or cooling capacity for later use, particularly beneficial in processes requiring consistent temperature control. Ice storage systems, for instance, can generate and store ice during nighttime hours when electricity rates are lower, then use it for cooling during peak daytime periods.

Recent technological advances have introduced phase-change materials (PCMs) that can store and release large amounts of energy during phase transitions. These materials are particularly effective in maintaining stable temperatures in industrial processes, reducing the energy required for heating and cooling cycles.

Implementation of hybrid storage systems, combining different storage technologies, has shown promising results in real-world applications. Case studies indicate that facilities implementing comprehensive storage solutions can achieve energy cost reductions of 15-30%, with some achieving ROI within 3-5 years. These systems also provide crucial backup power capabilities, ensuring operational continuity during grid disruptions.

Smart Building Management Systems

Modern building management systems represent a cornerstone of industrial energy efficiency, integrating various building functions into a cohesive, intelligent network. These systems combine HVAC, lighting, security, and other building operations through centralized control platforms, enabling real-time monitoring and optimization of energy consumption.

The implementation of smart building controls typically begins with the installation of an extensive sensor network throughout the facility. These sensors continuously collect data on occupancy patterns, temperature variations, lighting levels, and equipment performance. Advanced analytics platforms process this information to make automated adjustments, ensuring optimal energy usage while maintaining comfortable working conditions.

A key feature of modern building automation is the ability to create customized operational schedules based on actual facility usage. For instance, manufacturing plants operating multiple shifts can automatically adjust HVAC and lighting systems to match production schedules, eliminating energy waste during downtimes. Additionally, predictive maintenance algorithms help identify potential equipment failures before they occur, preventing energy-intensive emergency repairs and maintaining peak system efficiency.

Case studies from industrial facilities implementing smart building controls report energy savings between 20-30% annually. A recent implementation at a major automotive manufacturing plant demonstrated how intelligent scheduling and real-time adjustments reduced HVAC energy consumption by 25% while improving worker comfort levels.

To maximize the benefits of these systems, facility managers should focus on:

– Regular system calibration and sensor maintenance

– Staff training on system operation and optimization

– Integration with existing industrial control systems

– Continuous monitoring and adjustment of control parameters

– Regular analysis of performance data to identify improvement opportunities

The return on investment for smart building systems typically ranges from 2-5 years, depending on facility size and complexity. When combined with other energy efficiency initiatives, these systems provide a foundation for sustainable industrial operations while delivering substantial cost savings.

Improving energy efficiency in industrial settings requires a multi-faceted approach combining technological innovation, strategic planning, and committed implementation. The key strategies discussed throughout this article – from advanced building automation systems and smart sensors to renewable energy integration and waste heat recovery – form a comprehensive framework for achieving significant energy savings and operational improvements.

The future of industrial energy efficiency looks promising, with emerging technologies like artificial intelligence and machine learning poised to revolutionize how we monitor and optimize energy consumption. Industry leaders who have implemented these solutions report energy savings ranging from 20% to 40%, with some achieving even higher efficiencies through comprehensive retrofitting programs.

Success in energy efficiency initiatives depends heavily on organizational commitment, proper staff training, and regular monitoring of performance metrics. The most effective approaches combine immediate improvements, such as LED lighting upgrades and HVAC optimization, with longer-term strategies like building envelope improvements and renewable energy adoption.

Looking ahead, the industrial sector is expected to face increasing pressure to reduce energy consumption and carbon emissions. However, this challenge also presents opportunities for innovation and competitive advantage. Companies that invest in energy efficiency today will be better positioned to meet future regulatory requirements while benefiting from reduced operational costs and enhanced sustainability credentials.

To maximize results, organizations should develop comprehensive energy management plans, regularly audit their energy usage, and stay informed about emerging technologies and best practices. The return on investment for energy efficiency improvements continues to improve as technology advances and energy costs rise, making these initiatives increasingly attractive for forward-thinking industrial operations.