HVAC building codes represent the critical intersection of engineering precision, public safety, and environmental responsibility in modern construction. As climate change intensifies and energy efficiency becomes paramount, these regulations have evolved from simple ventilation requirements into comprehensive frameworks that shape the future of sustainable building design.

Recent updates to international building codes mandate up to 30% higher energy efficiency standards for HVAC systems, while introducing stringent requirements for smart building controls and renewable energy integration. These changes directly impact how construction professionals approach system design, equipment selection, and implementation strategies across commercial, residential, and industrial projects.

For construction professionals navigating this complex regulatory landscape, understanding current HVAC codes isn’t just about compliance—it’s about future-proofing buildings against evolving environmental challenges. From minimum efficiency requirements and ventilation standards to emerging requirements for building automation systems, these regulations form the foundation of modern HVAC design and installation practices.

This comprehensive guide examines the latest HVAC building codes, regional variations, and practical implementation strategies, providing construction professionals with essential insights for successful project execution in an increasingly regulated industry. Whether managing new construction or retrofitting existing structures, mastering these codes is crucial for delivering safe, efficient, and sustainable building solutions.

Modern HVAC Code Requirements for Climate Resilience

Energy Efficiency Standards

Energy efficiency standards for HVAC systems are governed by stringent performance requirements outlined in ASHRAE 90.1 and the International Energy Conservation Code (IECC). These standards establish minimum Seasonal Energy Efficiency Ratio (SEER) ratings for air conditioning units and Heating Seasonal Performance Factor (HSPF) values for heat pumps, which are continuously updated to reflect technological advancements and sustainable construction practices.

Current regulations require residential air conditioning systems to achieve a minimum SEER rating of 14-15, depending on the region, while commercial systems must meet even higher efficiency thresholds. Heat pumps must maintain an HSPF of at least 8.2, with many jurisdictions pushing for higher ratings to maximize energy savings.

Equipment performance is measured through standardized testing procedures, including Energy Efficiency Ratio (EER) for steady-state cooling efficiency and Integrated Energy Efficiency Ratio (IEER) for part-load performance. These metrics help contractors and building owners make informed decisions about system selection while ensuring compliance with local building codes.

The Department of Energy periodically reviews and updates these standards, typically providing a phase-in period of several years to allow manufacturers and contractors to adapt to new requirements. Building professionals must stay current with these evolving standards to ensure their projects meet or exceed minimum efficiency requirements while optimizing operational costs.

Ventilation and Air Quality Specifications

Recent updates to HVAC building codes have significantly enhanced ventilation and air quality requirements in response to climate change challenges. The current standards mandate a minimum of 15 cubic feet per minute (CFM) of outdoor air per occupant in commercial buildings, with specific adjustments based on occupancy type and building function.

Modern codes now require demand-controlled ventilation systems in spaces larger than 500 square feet with an occupant density greater than 25 people per 1000 square feet. These systems must incorporate CO2 sensors that automatically adjust ventilation rates based on actual occupancy levels, ensuring optimal air quality while maximizing energy efficiency.

MERV 13 filtration has become the new minimum standard for most commercial applications, representing a significant upgrade from previous MERV 8 requirements. This enhancement specifically addresses the increasing frequency of wildfires and air pollution events related to climate change.

Building codes now mandate the integration of economizer controls with ventilation systems in buildings over 33,000 square feet. These systems must be capable of providing 100% outdoor air when conditions are favorable, reducing mechanical cooling loads while maintaining indoor air quality.

Additional requirements include continuous monitoring of outdoor air delivery rates in critical spaces and the implementation of air quality measurement systems that can detect and respond to various pollutants. These specifications ensure buildings remain resilient and adaptable to changing environmental conditions while protecting occupant health.

Regional Adaptations in HVAC Regulations

Coastal Region Requirements

HVAC systems in coastal regions face unique challenges due to high humidity levels and corrosive salt air exposure, requiring specific code compliance measures. These requirements vary across different building code climate zones, with particular emphasis on corrosion resistance and moisture management.

All outdoor HVAC equipment must feature marine-grade components and protective coatings to prevent salt-air degradation. Condensing units and heat pumps require specialized aluminum or copper-based fins with protective treatments, while electrical connections must be sealed against moisture intrusion. Code requirements typically mandate stainless steel fasteners and mounting hardware rated for coastal environments.

Humidity control systems must meet stringent performance standards, including the capability to maintain indoor relative humidity below 60% during all operating conditions. This often necessitates the installation of dedicated dehumidification systems or enhanced moisture removal capabilities in standard HVAC equipment.

Ventilation systems require corrosion-resistant dampers and actuators, with specific attention to preventing salt-laden air from entering the building envelope. Fresh air intakes must incorporate moisture eliminators and specialized filtration systems designed for coastal environments. Additionally, drainage systems must be engineered to handle increased condensate production, with code-compliant overflow protection and corrosion-resistant drain pans.

Regular inspection protocols for coastal HVAC systems are typically more stringent, requiring quarterly evaluations of corrosion protection systems and moisture control mechanisms to maintain code compliance.

Urban Heat Island Mitigation

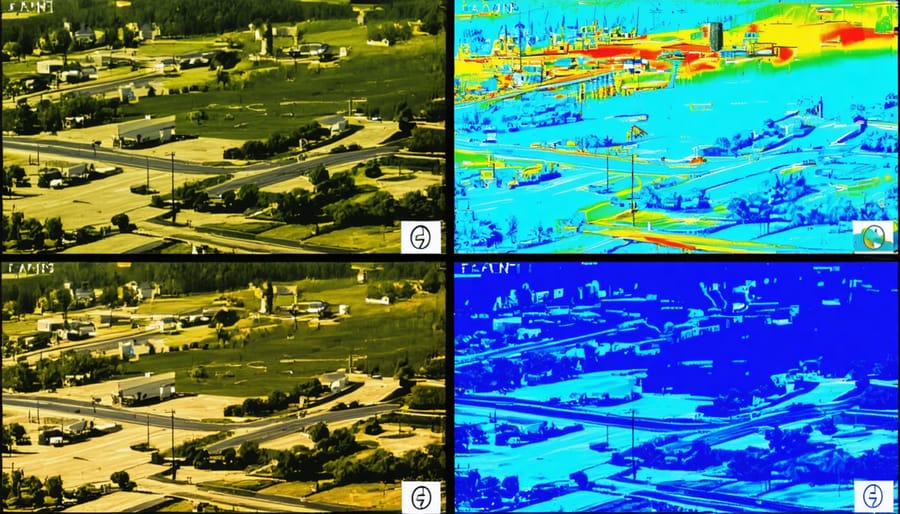

Building codes in dense urban environments increasingly emphasize urban heat island mitigation strategies through specialized HVAC requirements. These adaptations address the significant temperature differentials between urban cores and surrounding areas, which can reach up to 7°F (4°C) in major metropolitan regions.

Modern building codes mandate specific measures for urban HVAC systems, including higher minimum SEER ratings for cooling equipment and enhanced ventilation requirements. Requirements often include the installation of reflective roofing materials, strategic placement of outdoor HVAC units to minimize heat rejection into urban canyons, and the integration of green infrastructure elements.

Code provisions typically require mechanical engineers to account for microclimatic conditions in their load calculations, incorporating factors such as surrounding building thermal mass, reduced nighttime cooling potential, and anticipated future temperature increases. This often results in the specification of larger cooling capacities compared to suburban installations.

Additional requirements may include:

– Mandatory economizer systems for buildings over specific square footages

– Enhanced filtration systems to address urban air quality concerns

– Requirements for heat recovery systems in larger installations

– Specifications for variable frequency drives (VFDs) on major equipment

– Integration of smart building controls for optimal energy management

These regulations aim to enhance building performance while contributing to broader urban cooling efforts, ultimately reducing the collective impact of mechanical systems on urban heat accumulation.

Technology Integration and Smart Systems

Modern building codes are rapidly evolving to embrace smart HVAC technologies, reflecting the industry’s shift toward more efficient and automated climate control systems. The integration of Internet of Things (IoT) sensors, artificial intelligence, and building automation systems has prompted regulatory bodies to establish new standards for these technologies’ implementation and operation.

Recent code updates emphasize the importance of smart thermostats and zone control systems, requiring compatibility with building management systems (BMS) for enhanced energy efficiency. These regulations now mandate specific communication protocols and cybersecurity measures to protect connected HVAC systems from potential vulnerabilities while ensuring seamless integration with climate-resilient building design strategies.

Building codes now include provisions for automated fault detection and diagnostics (FDD) systems, which must be capable of identifying and reporting HVAC system inefficiencies and malfunctions. Requirements typically specify minimum monitoring points, data collection intervals, and reporting capabilities that these systems must provide to meet compliance standards.

The emergence of demand-response programs has led to new code requirements for HVAC systems to interface with utility networks. These regulations outline specific protocols for load shedding capabilities and automated response to grid signals, ensuring buildings can participate in energy management programs while maintaining occupant comfort.

Modern codes also address the integration of renewable energy systems with HVAC operations, requiring smart controls that can optimize system performance based on available solar or wind power. This includes specifications for energy storage systems and their integration with building automation systems.

Real-time energy monitoring and reporting capabilities are now mandatory in many jurisdictions, with codes specifying minimum requirements for data collection, storage, and accessibility. These requirements ensure building operators can track and optimize energy consumption while maintaining compliance with energy performance standards.

As technology continues to advance, building codes are increasingly focusing on predictive maintenance capabilities and system interoperability, ensuring that smart HVAC systems can adapt to future technological developments while maintaining operational efficiency and regulatory compliance.

Compliance and Implementation Strategies

Documentation Requirements

Proper documentation is essential for HVAC system compliance and certification. The process begins with detailed mechanical drawings and specifications that must be submitted for review during the permitting phase. These documents should include load calculations, equipment specifications, and system layouts following ASHRAE guidelines.

Testing and commissioning requirements typically involve three key phases. Initial testing verifies proper installation and basic functionality. Performance testing ensures the system meets designed capacities and efficiency ratings. Final commissioning confirms all components work together as an integrated system under various operating conditions.

Certification documentation must include:

– Equipment performance data

– Testing and balancing reports

– Commissioning results

– Energy compliance calculations

– System manuals and maintenance schedules

– Control system verification

– Air quality measurements

Professional certification is required for specific testing procedures. NEBB or AABC certified professionals must conduct air balancing tests, while certified energy auditors may need to verify energy performance metrics. All test results must be documented using standardized forms and procedures.

Maintenance documentation requirements include detailed service records, filter replacement logs, and regular inspection reports. These records must be maintained throughout the system’s lifecycle and be readily available for code enforcement inspections.

Digital documentation systems are increasingly common, allowing for better organization and accessibility of required records. Cloud-based platforms can streamline the documentation process while ensuring compliance with retention requirements.

Cost-Effective Compliance Solutions

Meeting HVAC building code requirements doesn’t have to strain your project budget. By implementing strategic approaches during the planning and execution phases, construction professionals can achieve compliance while optimizing costs.

Start with a thorough code analysis to identify specific requirements for your project. This prevents overengineering and unnecessary expenses. Consider value engineering opportunities that maintain compliance while reducing costs, such as optimizing ductwork layouts or selecting energy-efficient equipment that may qualify for utility incentives.

Preventive maintenance programs play a crucial role in cost-effective compliance. Regular inspections and maintenance help avoid expensive emergency repairs and ensure continuous code compliance. Documentation systems should be streamlined to reduce administrative overhead while maintaining necessary records for inspections.

Training staff on code requirements and proper system operation can significantly reduce long-term costs. Well-trained personnel can identify potential issues early, ensuring systems remain compliant without requiring costly interventions.

Consider phased implementation approaches when upgrading existing systems. This strategy allows for better budget management while ensuring continuous compliance. Working with experienced HVAC contractors who understand local codes can help identify cost-saving opportunities without compromising compliance.

Leverage building automation systems to monitor and optimize HVAC performance. While initial costs may be higher, these systems often pay for themselves through improved efficiency and reduced maintenance needs. They also provide valuable data for demonstrating ongoing code compliance during inspections.

Remember to factor in lifecycle costs when selecting equipment and systems. Sometimes, investing in higher-quality components initially can result in substantial savings over time while maintaining code compliance.

HVAC building codes continue to evolve in response to pressing environmental challenges and technological advancements. As we’ve explored, these regulations serve as critical guidelines for ensuring building safety, energy efficiency, and occupant comfort. The industry’s trajectory points toward increasingly stringent standards, particularly in energy conservation and sustainable practices. Construction professionals must stay informed about these changes while preparing for upcoming challenges, including the integration of smart technologies and renewable energy systems. With climate change driving policy updates and market demands shifting toward greener solutions, HVAC professionals should anticipate more frequent code revisions and stricter compliance requirements. Success in this dynamic landscape requires ongoing education, adaptability, and a commitment to implementing best practices that exceed minimum code requirements.