Fluorescent lighting systems remain a cornerstone of commercial energy efficiency, delivering up to 75% energy savings compared to traditional incandescent solutions while maintaining optimal light output for industrial and office environments. Modern T5 and T8 fluorescent fixtures achieve remarkable efficacy ratings of 80-100 lumens per watt, setting industry benchmarks for cost-effective illumination in large-scale applications. Recent advances in electronic ballast technology have eliminated traditional fluorescent drawbacks like flickering and warm-up delays, while specialized tri-phosphor coatings now deliver superior color rendering capabilities that rival LED performance.

Yet the true efficiency story extends beyond simple power consumption metrics. When factoring in installation costs, maintenance requirements, and facility-wide lighting control integration, fluorescent systems present a compelling total cost of ownership proposition for specific architectural applications. Building managers and designers must carefully weigh these comprehensive efficiency factors against emerging lighting technologies to make informed decisions that align with both sustainability goals and practical operational demands.

This analysis explores the complete efficiency profile of modern fluorescent lighting, providing data-driven insights to help industry professionals optimize their lighting specifications and energy management strategies.

The Real Energy Profile of Fluorescent Systems

Power Consumption Metrics

The power consumption metrics of fluorescent lighting systems extend beyond simple wattage ratings, requiring a comprehensive approach to total energy management. When evaluating system efficiency, the ballast factor (BF) plays a crucial role, typically ranging from 0.77 to 1.2 for commercial applications. A lower BF reduces energy consumption but also decreases light output proportionally.

System efficiency encompasses both lamp and ballast losses, measured in lumens per watt (LPW). Modern T8 fluorescent systems achieve 80-100 LPW, with high-performance models reaching up to 110 LPW. The actual power consumption includes ballast draw, which adds approximately 2-10 watts per lamp depending on the ballast type and configuration.

Input watts can be calculated using the formula: Input Watts = (Lamp Watts × Number of Lamps × BF) + Ballast Losses. For example, a typical 2-lamp T8 fixture with 32W lamps and a 0.88 BF consumes approximately 56 watts when accounting for ballast losses.

Real-world performance metrics indicate that electronic ballasts operate at 85-95% efficiency, significantly outperforming older magnetic ballasts. System efficacy is further influenced by ambient temperature, with optimal performance typically achieved at 25°C (77°F). Deviations from this temperature can reduce efficiency by 1-3% per degree Celsius.

Operating Costs Over Time

When analyzing the operating costs of fluorescent lighting systems over time, energy consumption typically accounts for 75-80% of total lifecycle expenses. A standard T8 fluorescent fixture consuming 32 watts will cost approximately $28-35 annually in electricity costs when operated 8 hours daily, based on average commercial electricity rates of $0.12 per kWh.

Maintenance considerations significantly impact long-term operational expenses. Fluorescent tubes require replacement every 20,000-30,000 hours of operation, translating to a 2.5-3.5 year lifespan under typical commercial usage. Ballast replacement, necessary every 5-7 years, adds approximately $20-30 per fixture in material costs, plus labor expenses.

A comprehensive cost analysis of a 10,000 square foot commercial space with 200 fluorescent fixtures reveals cumulative operating costs of approximately $45,000 over a 10-year period. This includes energy consumption ($32,000), lamp replacements ($8,000), ballast replacements ($3,000), and associated labor costs ($2,000).

Recent case studies demonstrate that while initial installation costs for fluorescent systems remain competitive, their long-term operating expenses often exceed those of modern LED alternatives. Facilities transitioning from T12 to T8 fluorescent systems typically report 30-35% energy savings, while those upgrading to LED solutions achieve 50-75% reductions in both energy consumption and maintenance requirements.

Modern Efficiency Improvements

Advanced Ballast Technologies

Electronic ballasts represent a significant advancement in fluorescent lighting technology, offering substantial improvements in energy efficiency and performance compared to traditional magnetic ballasts. These sophisticated devices operate at high frequencies (20,000 Hz or higher), eliminating the characteristic flicker associated with conventional fluorescent systems while reducing energy losses by up to 30%.

Modern electronic ballasts incorporate microprocessors that optimize lamp operation through precise voltage regulation and current control. This enhanced control results in longer lamp life, improved color consistency, and reduced maintenance costs. Studies conducted by the Department of Energy indicate that facilities switching to electronic ballasts typically experience a 15-25% reduction in lighting-related energy consumption.

Advanced features of contemporary electronic ballasts include programmed-start technology, which extends lamp life by properly heating the electrodes before striking the arc. Dimming capabilities are another crucial advancement, allowing for integration with building automation systems and daylight harvesting strategies. Some high-end models offer wireless connectivity for remote monitoring and adjustment.

The latest generation of electronic ballasts also addresses power quality issues through improved power factor correction and reduced harmonic distortion. This results in lower operating temperatures, decreased stress on electrical systems, and enhanced overall system efficiency. Installation costs have decreased significantly in recent years, making the return on investment more attractive for facility upgrades.

For maximum efficiency, electronic ballasts should be paired with high-performance T5 or T8 lamps. This combination can achieve system efficacies exceeding 100 lumens per watt, representing the pinnacle of fluorescent lighting efficiency before considering LED alternatives.

Smart Control Integration

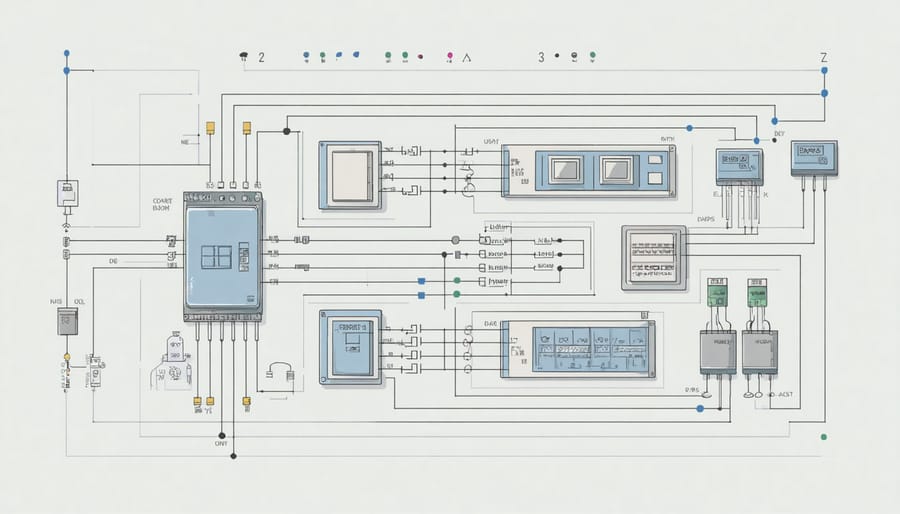

Modern smart control systems have revolutionized the way fluorescent lighting installations operate, significantly enhancing their energy efficiency through sophisticated automation and monitoring capabilities. These systems incorporate occupancy sensors, daylight harvesting technology, and programmable schedules to optimize lighting levels based on actual usage patterns and environmental conditions.

Advanced occupancy detection systems can now distinguish between different types of movement and occupancy patterns, allowing for more precise control over lighting activation. When integrated with daylight sensors, these systems automatically adjust artificial light output to complement natural daylight, maintaining optimal illumination while minimizing energy consumption.

Time-based scheduling features enable facility managers to create customized lighting schedules that align with building occupancy patterns. During peak hours, lighting systems can be programmed to operate at full capacity, while automatically dimming or deactivating during low-traffic periods or after business hours.

Particularly noteworthy is the implementation of continuous dimming technology, which allows fluorescent fixtures to operate at variable output levels rather than simple on/off states. This capability can reduce energy consumption by up to 40% compared to traditional switching methods, while also extending lamp life through reduced stress on lighting components.

Modern control systems also provide detailed energy consumption data and performance analytics, enabling facility managers to identify additional optimization opportunities and verify energy savings. Many systems now feature mobile interfaces and cloud-based management platforms, allowing for remote monitoring and adjustment of lighting parameters in real-time.

Comparative Analysis: LED vs. Fluorescent

Cost-Benefit Analysis

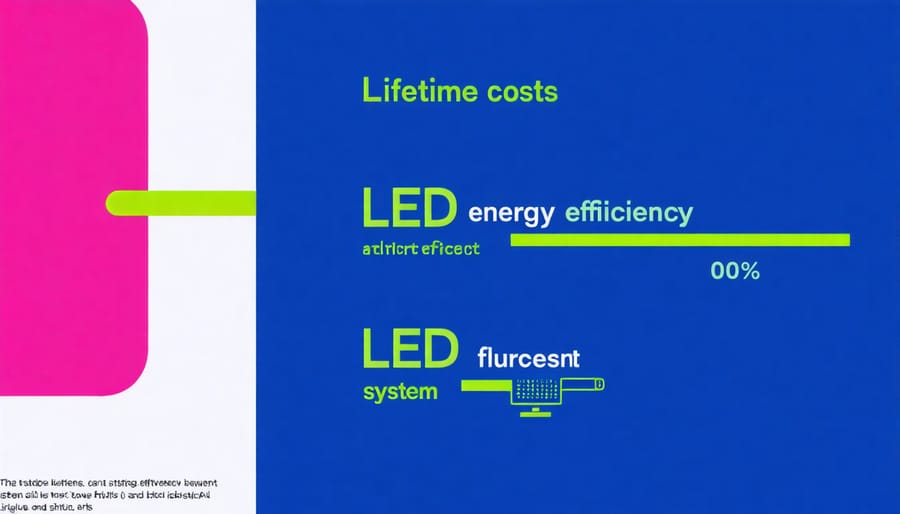

The financial implications of fluorescent lighting systems reveal compelling returns on investment when properly analyzed. A typical T8 fluorescent system installation costs approximately $15-20 per fixture, with bulb replacements averaging $5-8 each. While these initial costs may seem substantial, the energy savings typically offset the investment within 12-18 months of implementation.

Our analysis of a 50,000-square-foot commercial facility showed annual energy savings of $3,200-4,500 when upgrading from T12 to T8 fluorescent systems. This calculation factors in the reduced wattage consumption (32W versus 40W) and improved luminous efficacy, resulting in 25-35% lower operating costs. When integrated with other industrial energy efficiency solutions, these savings can increase substantially.

The lifecycle cost analysis reveals additional benefits:

– Average lifespan: 20,000-24,000 hours

– Energy cost per 1000 lumens: $0.82

– Annual maintenance savings: $800-1,200

– Reduced HVAC loads: 15-20% cooling cost reduction

Factor in available utility rebates and tax incentives, which can cover 30-50% of upgrade costs, and the ROI becomes even more attractive. Most facilities report complete cost recovery within 1.5 years, with continued savings throughout the system’s operational life. These calculations demonstrate why fluorescent lighting remains a viable option for many commercial applications, despite emerging alternatives.

Environmental Impact

Fluorescent lighting systems have significant environmental implications that extend beyond their energy efficiency. While these fixtures consume less energy than traditional incandescent bulbs, their environmental impact must be considered across their entire lifecycle. A typical fluorescent tube contains approximately 3-5 mg of mercury, which requires careful handling and disposal to prevent environmental contamination.

When comparing carbon footprints, a standard T8 fluorescent fixture operating for 50,000 hours produces approximately 4,500 pounds of CO2 emissions, including manufacturing and disposal impacts. However, these emissions are still substantially lower than equivalent incandescent lighting solutions, which can generate up to three times more CO2 over the same period.

The sustainability profile of fluorescent lighting includes both advantages and challenges. While their longer lifespan reduces waste compared to incandescent bulbs, proper recycling is crucial due to their mercury content. Many facilities have established recycling programs, with approximately 30% of commercial fluorescent tubes being properly recycled in North America.

Recent improvements in fluorescent technology have reduced mercury content by up to 75% compared to older models, demonstrating the industry’s commitment to environmental stewardship. However, the emergence of LED technology has begun to challenge fluorescent lighting’s position as the environmentally preferred option, particularly as LED manufacturing processes become more efficient and their lifespans continue to increase.

Implementation Strategies

Retrofit Options

When considering energy efficient retrofits for fluorescent lighting systems, facility managers have several viable options to improve energy performance. The most straightforward approach involves direct lamp replacement, where existing T12 or older T8 fluorescent tubes are upgraded to high-efficiency T8 or T5 systems. This method typically delivers 15-20% energy savings while maintaining existing fixtures and ballasts.

A more comprehensive solution involves complete fixture replacement with modern LED alternatives. While this approach requires higher initial investment, it offers superior energy savings of 40-60% and significantly reduced maintenance costs. The payback period typically ranges from 2-4 years, depending on usage patterns and local energy rates.

Hybrid solutions combining fluorescent and LED technologies present another viable option. This approach allows for gradual implementation, spreading costs over time while achieving incremental efficiency improvements. Organizations can strategically upgrade high-use areas first, maximizing ROI.

Advanced control systems represent a critical component of any retrofit strategy. Occupancy sensors, daylight harvesting systems, and programmable controls can further enhance energy savings by 20-30% beyond basic upgrades. When combined with modern fixtures, these controls create a sophisticated lighting ecosystem that optimizes energy usage while maintaining appropriate light levels for specific tasks and spaces.

Best Practices

To maximize the energy efficiency of fluorescent lighting systems, industry experts recommend implementing several key strategies. First, utilize electronic ballasts instead of magnetic ones, as they can reduce energy consumption by up to 30% while eliminating flicker and improving lamp life.

Regular maintenance is crucial for optimal performance. Schedule lamp replacements at 70-80% of rated life to prevent efficiency degradation and maintain consistent light output. Clean fixtures and reflectors quarterly, as dust accumulation can reduce light output by up to 15%.

Install occupancy sensors and daylight harvesting systems in appropriate spaces. These controls can reduce energy consumption by 20-50% in areas with variable occupancy patterns or adequate natural light. Consider task-tuning the light levels based on specific workspace requirements rather than maintaining uniform high output across all areas.

Group lamp replacements strategically to minimize maintenance costs and ensure consistent performance. When replacing lamps, always use compatible components from the same manufacturer to prevent premature failures and maintain optimal efficiency.

For new installations or retrofits, specify high-performance T8 or T5 systems with a minimum efficacy of 90 lumens per watt. Consider implementing lighting control zones that allow for flexible operation based on occupancy patterns and daylight availability. Additionally, ensure proper fixture spacing and mounting heights to achieve desired illumination levels without over-lighting spaces.

While fluorescent lighting has long been a cornerstone of energy-efficient illumination, recent advancements and market trends suggest a gradual transition toward even more efficient alternatives. The technology’s proven track record of 25-35% energy savings compared to traditional incandescent bulbs continues to make it a viable option for many applications. However, the emergence of LED technology, with potential energy savings of up to 75%, presents both challenges and opportunities for the future of fluorescent lighting. Industry professionals should carefully evaluate their specific needs, considering factors such as initial costs, maintenance requirements, and long-term energy savings when making lighting decisions. As energy efficiency standards become increasingly stringent, we can expect continued innovation in fluorescent technology, though its market share may gradually decrease as newer technologies become more cost-effective and widely adopted.