Revolutionizing modern manufacturing, composite 3D printing technology represents a quantum leap in materials engineering and production capabilities. By combining advanced polymers, carbon fibers, and other reinforcement materials, composite 3D printers create components that rival traditional manufacturing methods in strength while offering unprecedented design flexibility. These systems enable construction professionals to fabricate complex geometries with enhanced mechanical properties, reduced weight, and superior durability—characteristics previously unattainable through conventional methods.

The integration of continuous fiber reinforcement with precise digital control has transformed how we approach structural components, tooling, and end-use parts in construction applications. Industry leaders are increasingly adopting this technology to reduce material waste, accelerate production timelines, and achieve cost efficiencies of up to 50% compared to traditional manufacturing processes. From aerospace-grade components to architectural elements, composite 3D printing is redefining the boundaries between structural performance and manufacturing efficiency.

This transformative technology positions construction firms at the forefront of innovation, enabling them to deliver sophisticated solutions while maintaining competitive advantages in increasingly demanding markets.

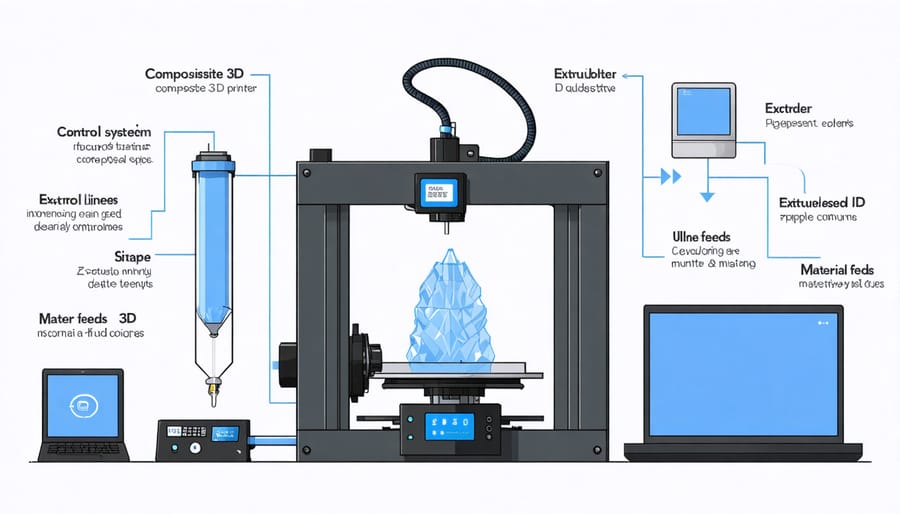

Understanding Composite 3D Printing Technology

Core Components and Mechanisms

A composite 3D printer consists of several critical components working in harmony to produce fiber-reinforced parts. The foundation is a robust gantry system that provides precise XYZ movement control, typically achieving accuracy within 0.1mm. The dual extrusion system incorporates two primary mechanisms: a thermoplastic extruder for the matrix material and a fiber placement head for continuous reinforcement.

The fiber feeding mechanism utilizes specialized rollers and tensioners to maintain consistent fiber tension during printing. A cutting mechanism, integrated into the fiber placement head, allows for precise fiber termination between layers. The print bed features a heated platform, usually maintaining temperatures between 60-120°C, ensuring optimal layer adhesion and preventing warpage.

Control systems coordinate these components through advanced firmware, managing variables like extrusion rates, fiber placement angles, and temperature profiles. The material delivery system includes climate-controlled storage for both composite filaments and reinforcement fibers, preventing moisture absorption that could compromise print quality. Thermal management systems maintain precise temperature control throughout the printing process, essential for achieving optimal fiber-matrix bonding and mechanical properties in the final part.

Material Compatibility and Properties

Composite 3D printers accommodate a diverse range of construction materials, each offering distinct mechanical and structural properties. The most commonly utilized materials include fiber-reinforced polymers (FRP), carbon fiber composites, and glass fiber-reinforced plastics (GFRP). These materials exhibit exceptional strength-to-weight ratios, with carbon fiber composites delivering tensile strengths up to 3.5 GPa while maintaining minimal weight characteristics.

Material selection significantly influences the final product’s performance attributes. Fiber-reinforced thermoplastics demonstrate superior impact resistance and fatigue strength, making them ideal for load-bearing components. Glass fiber composites offer excellent chemical resistance and thermal stability, with operating temperatures ranging from -50°C to 140°C.

The printing process requires precise material preparation, with fiber content typically ranging between 15-60% by volume. Higher fiber concentrations generally yield improved mechanical properties but demand more sophisticated printing parameters. Material compatibility also extends to various matrix materials, including nylon, PEEK, and epoxy-based systems, each contributing unique characteristics to the final composite structure.

Real-World Applications in Construction

Structural Elements and Components

Composite 3D printing has demonstrated remarkable capabilities in producing high-performance structural elements across various construction applications. Recent testing has shown that fiber-reinforced composite beams printed using this technology can achieve flexural strengths of up to 150 MPa, surpassing traditional concrete elements by a significant margin.

Load-bearing walls manufactured through composite 3D printing have exhibited exceptional compression strength, typically ranging from 40-60 MPa, while maintaining a considerably lower weight compared to conventional concrete walls. These elements incorporate continuous fiber reinforcement, resulting in superior tensile properties and crack resistance.

Column structures produced via composite 3D printing have demonstrated remarkable stability and load-bearing capacity. Testing has revealed that these columns can sustain vertical loads of up to 200 kN while maintaining structural integrity. The integration of carbon fiber reinforcement has proven particularly effective, increasing the overall strength-to-weight ratio by approximately 40%.

Connection nodes and joints, critical components in any structural system, have shown excellent performance metrics when 3D printed using composite materials. These elements have demonstrated shear strengths exceeding 75 MPa and remarkable fatigue resistance, with some specimens maintaining structural integrity beyond 100,000 loading cycles.

Notably, composite 3D printed floor panels have achieved span-to-depth ratios of up to 30:1, while maintaining deflection within acceptable limits under service loads. The incorporation of glass fiber reinforcement in these panels has resulted in enhanced impact resistance and improved long-term durability.

These performance metrics underscore the potential of composite 3D printing in producing structural elements that meet or exceed traditional construction standards while offering advantages in terms of weight reduction and design flexibility.

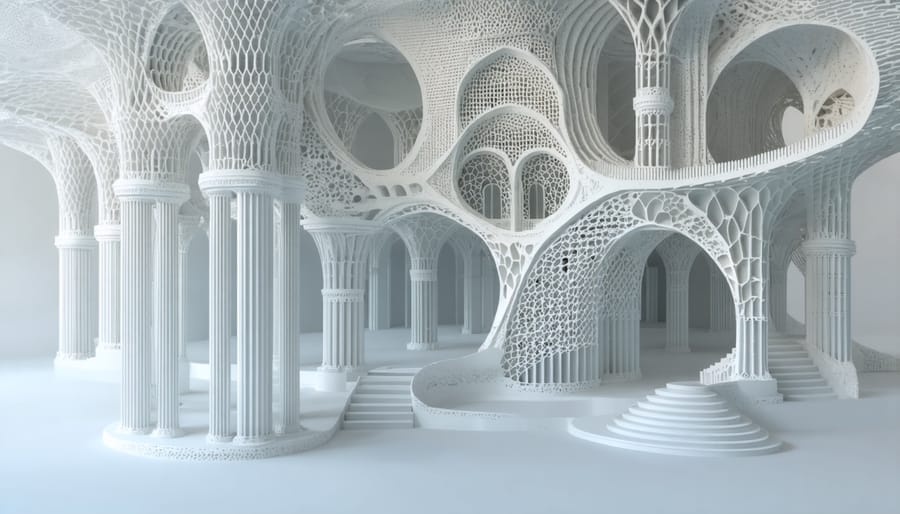

Custom Architectural Features

Composite 3D printing has revolutionized architectural design innovation, enabling the creation of complex geometric structures previously impossible or cost-prohibitive with traditional construction methods. The technology excels in producing intricate lattice structures, bio-inspired forms, and customized architectural elements that combine both aesthetic appeal and structural integrity.

Notable achievements include the production of load-bearing facade components with integrated cooling channels, complex nodal connections for space frame structures, and customized architectural panels featuring variable density patterns. The precision of composite printing allows architects to implement sophisticated parametric designs while maintaining strict tolerances and structural requirements.

Recent projects have demonstrated the capability to create multi-material architectural elements that combine the strength of fiber-reinforced composites with the flexibility of thermoplastics. These hybrid components can incorporate functional features such as thermal insulation, acoustic dampening, and integrated utility passages within a single printed structure.

The technology particularly shines in creating topology-optimized structural components, where material is distributed precisely where needed for maximum strength while minimizing weight. This approach has resulted in up to 40% material savings compared to traditional manufacturing methods, while maintaining or exceeding performance requirements.

Architects and engineers are now leveraging composite 3D printing to produce custom connection nodes, decorative elements, and complex geometric forms that seamlessly integrate with conventional building materials. The ability to rapidly prototype and iterate designs has significantly reduced the time and cost associated with developing unique architectural features, while ensuring precise quality control throughout the manufacturing process.

Cost and Efficiency Benefits

Material and Labor Savings

Implementing composite 3D printing technology can lead to significant material and labor cost reductions compared to traditional construction methods. According to recent industry studies, projects utilizing composite 3D printing have demonstrated material savings of 30-45% through optimized design and reduced waste. This efficiency stems from precise material deposition and the ability to create complex geometries without excess material consumption.

Labor costs typically decrease by 40-60% when employing composite 3D printing systems, primarily due to automated processes requiring fewer workers and reduced construction time. A comprehensive construction cost optimization analysis across multiple projects reveals that a traditional construction team of 10-12 workers can be reduced to 3-4 operators managing the 3D printing system.

Case studies from recent commercial projects demonstrate that the initial investment in composite 3D printing technology can be offset within 12-18 months through reduced material and labor expenses. For example, a mid-sized commercial building project achieved a 35% reduction in overall construction costs, with material savings of $45,000 and labor savings of $75,000 compared to conventional methods.

The technology’s ability to work continuously, minimize human error, and reduce material waste contributes to these cost savings. Additionally, the precision of composite 3D printing reduces rework requirements and associated costs, while standardizing quality across projects.

Project Timeline Optimization

Composite 3D printing technology has revolutionized construction project timelines, offering significant optimization opportunities throughout the building process. Studies indicate that projects utilizing composite 3D printing technology can achieve time savings of 50-70% compared to traditional construction methods.

The acceleration of project delivery stems from several key factors. First, the automated nature of 3D printing eliminates many labor-intensive tasks and reduces human error-related delays. Components can be manufactured simultaneously, allowing for parallel production processes that dramatically compress construction schedules.

Recent case studies demonstrate these benefits in practice. A multi-story commercial building project in Singapore achieved a 60% reduction in construction time by implementing composite 3D printing for structural elements and facade components. The technology enabled 24/7 production capabilities while maintaining consistent quality standards.

Project managers can now develop more accurate timeline predictions through advanced simulation software integrated with 3D printing systems. This precision in scheduling enables better resource allocation and reduces costly delays. Additionally, weather-related interruptions are minimized as many components can be manufactured in controlled environments.

The technology also streamlines the approval and revision process. Digital models can be quickly adjusted and reprinted without the extensive retooling required in traditional methods. This agility in responding to design changes or regulatory requirements prevents lengthy project delays.

For optimal results, construction teams should integrate composite 3D printing early in the planning phase, allowing for comprehensive timeline optimization across all project stages.

Future Prospects and Industry Impact

Technological Advancements

Recent advancements in composite 3D printing technology are revolutionizing construction capabilities and material performance. Multi-material printing systems now enable simultaneous deposition of different composite materials, allowing for optimized structural properties within a single print. Advanced fiber placement technologies can precisely control fiber orientation, resulting in enhanced mechanical properties and load-bearing capabilities.

Artificial intelligence and machine learning algorithms are being integrated into printer control systems, enabling real-time adjustments to printing parameters and predictive maintenance. These smart systems can detect and correct printing anomalies, ensuring consistent quality across large-scale projects.

New developments in printhead technology have improved the precision of fiber-matrix distribution, while enhanced thermal management systems allow for better control of curing processes. This has led to stronger inter-layer adhesion and reduced void formation in printed components.

Researchers are also developing novel composite materials specifically engineered for 3D printing applications. These include self-healing composites that can repair minor damage automatically and smart composites that incorporate sensors for structural health monitoring.

The integration of robotics and automation has expanded printing capabilities to include complex geometries and larger structures. Combined with advanced scanning and quality control systems, these innovations are improving print accuracy and reducing material waste. Industry experts predict that upcoming developments will focus on increasing print speeds, expanding material compatibility, and implementing sustainable practices in composite printing processes.

Market Growth Projections

The composite 3D printing market is experiencing remarkable growth, with industry analysts projecting a compound annual growth rate (CAGR) of 39.2% from 2023 to 2028. This explosive expansion is primarily driven by increasing adoption across aerospace, automotive, and construction sectors, where demand for lightweight, durable materials continues to rise.

Recent market research indicates that the global composite 3D printing industry, valued at $385 million in 2022, is expected to reach $2.3 billion by 2028. Construction industry adoption is particularly noteworthy, with a projected 45% increase in implementation over the next five years, as more firms recognize the technology’s potential for creating complex structural components and reducing material waste.

Key growth indicators include the rising number of patents filed for composite 3D printing technologies, increasing from 1,200 in 2019 to over 3,000 in 2022. Major manufacturing hubs in North America and Europe are leading this expansion, with Asia-Pacific regions showing the fastest adoption rates, particularly in industrial applications.

Industry experts anticipate breakthrough developments in material science, with new composite formulations expected to enter the market by 2025. These innovations will likely focus on enhanced strength-to-weight ratios, improved thermal properties, and better printability, further driving market growth and technological advancement in the construction sector.

Composite 3D printing represents a transformative advancement in construction technology, offering unprecedented possibilities for the building industry. The combination of enhanced structural integrity, design flexibility, and material efficiency positions this technology as a cornerstone of modern construction innovation. Through reduced labor costs, minimized material waste, and accelerated project timelines, composite 3D printing delivers tangible economic benefits that directly impact the bottom line.

Industry adoption of this technology is not just about staying competitive; it’s about embracing a solution that addresses many long-standing challenges in construction. The ability to create complex geometries while maintaining structural integrity opens new horizons for architectural expression and engineering efficiency. Furthermore, the technology’s contribution to sustainable construction practices aligns with growing environmental regulations and corporate responsibility initiatives.

As we look to the future, the construction industry stands at a pivotal moment. Early adopters of composite 3D printing technology are already experiencing significant advantages in project delivery and cost optimization. For those yet to implement this technology, the evidence clearly demonstrates its potential to revolutionize construction processes and outcomes.

The time for hesitation has passed. Construction professionals must seriously consider integrating composite 3D printing into their operations to remain competitive and meet evolving industry demands. With continued technological advancement and growing industry acceptance, composite 3D printing is not just an option for the future – it’s a necessity for the present.