Transform your construction project outcomes by mastering the strategic procurement framework that industry leaders leverage. Implement comprehensive vendor prequalification matrices to evaluate financial stability, safety records, and past performance metrics before contract award. Establish standardized procurement protocols that integrate real-time material cost tracking, lead time management, and quality control checkpoints across all supplier relationships. Deploy digital procurement platforms to automate purchase orders, track vendor compliance, and maintain transparent communication channels with key stakeholders.

Modern construction procurement demands precise orchestration of multiple vendor relationships while maintaining strict budget controls and project timelines. Success hinges on establishing clear performance metrics, implementing robust risk management strategies, and maintaining seamless coordination between project teams and suppliers. Industry leaders who excel in procurement consistently deliver projects under budget and ahead of schedule by leveraging data-driven vendor selection processes and maintaining strong supplier relationships through systematic performance monitoring and continuous improvement programs.

Strategic Procurement Planning in Construction

Risk Assessment and Mitigation

Effective risk assessment in procurement requires a systematic approach to identify, evaluate, and mitigate potential threats to project success. Begin by conducting thorough vendor capability assessments, examining financial stability, past performance, and operational capacity. Create a risk matrix that categorizes risks based on likelihood and potential impact, focusing on critical areas such as supply chain disruptions, quality control issues, and regulatory compliance.

Implement preventive measures including performance bonds, warranty requirements, and insurance coverage requirements. Establish clear contractual safeguards with specific remedies for non-performance or quality issues. Regular vendor audits and performance monitoring help identify emerging risks before they escalate into major problems.

Develop contingency plans for high-impact risks, such as maintaining relationships with backup suppliers and establishing emergency procurement procedures. Consider market conditions that might affect material availability or pricing, and incorporate appropriate escalation clauses in contracts. Document all risk management procedures and maintain clear communication channels with vendors to ensure quick response to emerging issues.

Regularly review and update risk assessments as project conditions change, keeping stakeholders informed of significant developments and mitigation strategies.

Budget Optimization Techniques

Effective cost control strategies are essential for maximizing procurement value while maintaining project quality. Value engineering begins with detailed spend analysis and category management, enabling organizations to identify potential savings opportunities across their supply chain. Implementation of strategic sourcing initiatives, including bulk purchasing agreements and early supplier involvement, can yield significant cost reductions without compromising quality standards.

Advanced techniques such as should-cost modeling and total cost of ownership analysis help procurement teams make informed decisions beyond initial purchase prices. By establishing clear cost benchmarks and implementing variance tracking systems, organizations can proactively manage budget deviations and optimize spending patterns.

Regular supplier performance evaluations coupled with competitive bidding processes ensure market-aligned pricing while maintaining vendor relationships. Organizations should also consider implementing automated procurement systems that streamline processes and reduce administrative costs. These systems can track spending patterns, identify cost-saving opportunities, and provide real-time budget visibility, enabling more strategic decision-making in vendor selection and contract negotiations.

Vendor Selection and Evaluation

Qualification Criteria

Establishing robust qualification criteria is essential for successful vendor selection in construction procurement. Following established vendor evaluation best practices, organizations should assess potential suppliers across multiple key metrics.

Financial stability stands as a primary consideration, requiring analysis of vendors’ credit ratings, financial statements, and business longevity. This evaluation helps ensure partners can sustain long-term project commitments and weather market fluctuations.

Technical capability and expertise must be thoroughly verified through past project portfolios, certifications, and industry-specific qualifications. Vendors should demonstrate proficiency in relevant construction methodologies and compliance with industry standards.

Quality management systems and safety records require careful scrutiny. ISO certifications, documented quality control procedures, and workplace safety statistics provide crucial insights into operational excellence and risk management capabilities.

Resource capacity and scalability assessment ensures vendors can handle project demands while maintaining consistent quality. This includes evaluation of equipment availability, workforce capabilities, and supply chain relationships.

Past performance metrics, including on-time delivery rates, cost adherence, and client testimonials, offer valuable indicators of reliability. References from similar projects should be thoroughly verified to confirm track record.

Consider geographical presence and local market knowledge, particularly for projects requiring regional expertise or compliance with local regulations. Vendors should demonstrate understanding of local construction practices and building codes.

Performance Monitoring Systems

Performance monitoring systems are essential tools for evaluating vendor effectiveness and ensuring project success in construction procurement. These systems typically incorporate key performance indicators (KPIs) that measure critical aspects such as delivery timeliness, quality compliance, safety standards adherence, and cost management.

Modern vendor performance tracking utilizes integrated software solutions that provide real-time data collection and analysis. These platforms often feature automated scorecards that evaluate vendors across predetermined metrics, including response times, defect rates, and compliance with project specifications. Construction firms increasingly rely on digital dashboards that offer visual representations of vendor performance trends and alert project managers to potential issues before they escalate.

Effective monitoring systems should include:

– Regular performance reviews and assessments

– Documentation of delivery and quality metrics

– Safety incident tracking and reporting

– Cost variance analysis

– Compliance monitoring for regulatory requirements

– Sustainability and environmental impact measures

Industry leaders implement structured feedback loops where performance data directly influences vendor selection and contract renewal decisions. This data-driven approach enables construction companies to maintain high-quality vendor relationships while systematically identifying areas for improvement.

To maximize effectiveness, monitoring systems should be calibrated to project-specific requirements and integrated with existing project management tools. Regular system audits ensure that performance metrics remain relevant and aligned with evolving project needs and industry standards.

Contract Management Best Practices

Negotiation Strategies

Effective negotiation in construction procurement requires a balanced approach that prioritizes both cost optimization and relationship building. Start by thoroughly researching market rates, vendor capabilities, and alternative suppliers to establish a strong negotiating position. Focus on identifying win-win scenarios that create value for both parties rather than pursuing aggressive price reduction tactics that might damage long-term relationships.

Key strategies include leveraging volume commitments for better pricing, establishing clear performance metrics, and incorporating early payment incentives. When negotiating with strategic suppliers, consider implementing value engineering proposals that can reduce costs while maintaining quality standards. Bundle similar purchases across projects to increase buying power and attract more competitive offers.

Maintain professional communication throughout the negotiation process, clearly articulating requirements, timelines, and quality expectations. Document all discussions and agreements meticulously, and be prepared to offer reasonable compromises when necessary. Consider implementing structured negotiation frameworks that address both commercial terms and operational requirements.

For critical supplies or services, develop contingency plans and maintain relationships with alternative vendors to strengthen your negotiating position. Remember that successful negotiations often lead to long-term partnerships that can bring additional value through innovation, reliability, and preferential treatment during supply chain disruptions.

Compliance and Documentation

Effective compliance and documentation systems form the backbone of successful procurement and vendor management in construction projects. A robust compliance framework should include systematic documentation of all vendor interactions, contractual agreements, and performance evaluations.

Organizations must maintain detailed records of vendor qualifications, certifications, and insurance documentation, ensuring they remain current throughout the project lifecycle. This includes tracking safety certifications, licenses, and any industry-specific requirements mandated by local regulations.

Digital document management systems prove invaluable for organizing and storing procurement-related documentation, including bid submissions, contracts, change orders, and payment records. These systems should implement version control and audit trails to track modifications and maintain document integrity.

Regular compliance audits help identify potential gaps in documentation and ensure adherence to contractual obligations. Construction firms should establish clear protocols for document retention, including specified timeframes for storing different types of records and secure disposal procedures.

Key documentation requirements typically include:

– Vendor qualification documents

– Bid submissions and evaluations

– Executed contracts and amendments

– Performance metrics and evaluations

– Payment records and invoicing history

– Insurance certificates and bonds

– Quality control reports

– Safety compliance records

Implementing standardized templates and checklists helps maintain consistency in documentation practices across multiple projects and vendors.

Technology Integration in Procurement

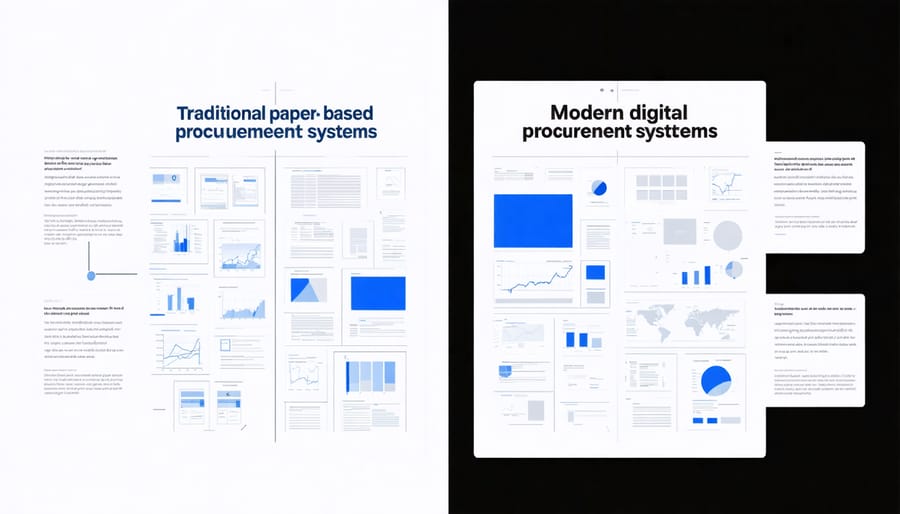

Digital Procurement Solutions

Modern construction projects increasingly rely on digital procurement solutions to streamline operations and enhance efficiency. These platforms integrate various procurement functions, from vendor selection to payment processing, into unified systems that promote transparency and accountability. Key features typically include automated purchase order generation, real-time inventory tracking, and vendor performance analytics.

Leading procurement software solutions offer specialized modules for construction-specific needs, such as material quantity takeoffs, bid management, and subcontractor prequalification. Cloud-based platforms enable remote access and collaboration, particularly valuable for large-scale projects with multiple stakeholders. Advanced systems incorporate artificial intelligence for predictive analytics, helping project managers anticipate supply chain disruptions and optimize procurement timing.

Integration capabilities with existing enterprise resource planning (ERP) systems and building information modeling (BIM) platforms ensure seamless data flow across project management functions, reducing redundancy and minimizing errors in procurement processes.

Data Analytics for Decision Making

Data analytics has revolutionized procurement decision-making in construction projects by enabling evidence-based strategies and predictive insights. Modern procurement teams leverage advanced analytics tools to analyze spending patterns, evaluate vendor performance metrics, and identify cost-saving opportunities across the supply chain.

Key performance indicators (KPIs) such as on-time delivery rates, quality compliance, and cost variance are continuously monitored through integrated dashboards. This real-time data tracking allows procurement managers to make informed decisions about vendor selection, contract negotiations, and risk mitigation strategies.

Predictive analytics helps identify potential supply chain disruptions before they occur, enabling proactive measures to maintain project timelines. Historical data analysis also supports better forecasting of material requirements and pricing trends, leading to more accurate budgeting and reduced waste.

By implementing data-driven procurement strategies, construction companies typically achieve 15-20% cost savings while significantly improving vendor relationship management through objective performance assessment and feedback mechanisms. This systematic approach to data analytics ensures continuous improvement in procurement processes and vendor partnerships.

The future of construction procurement and vendor management is rapidly evolving, driven by technological advancement and changing industry demands. Digital transformation continues to reshape traditional processes, with integrated procurement platforms and AI-powered analytics becoming essential tools for successful project delivery. Organizations that embrace these innovations while maintaining strong vendor relationships will be better positioned to overcome supply chain challenges and optimize project outcomes.

Key takeaways from modern procurement practices emphasize the importance of strategic sourcing, risk management, and sustainable vendor partnerships. The integration of data-driven decision-making, coupled with robust compliance frameworks, has become crucial for maintaining competitive advantage in today’s construction landscape. Additionally, the growing focus on sustainability and environmental responsibility is reshaping vendor selection criteria and procurement strategies.

Looking ahead, we can expect to see increased adoption of blockchain technology for contract management, greater emphasis on supply chain transparency, and the emergence of more sophisticated digital procurement solutions. Success in construction procurement will depend on organizations’ ability to balance technological innovation with traditional relationship-building skills while maintaining agility in an ever-changing market environment.