Predictive analytics in R is revolutionizing construction safety by detecting potential hazards before they materialize, offering a powerful alternative to traditional risk management methods. Advanced machine learning algorithms, powered by R’s robust statistical capabilities, now process vast amounts of construction site data to forecast accident probabilities with up to 85% accuracy. Leading construction firms implementing R-based predictive models have reported a 40% reduction in workplace incidents and a 30% decrease in insurance premiums within the first year of deployment.

This data-driven approach transforms historical incident reports, environmental conditions, worker behavior patterns, and equipment maintenance records into actionable insights that protect lives and assets. By leveraging R’s sophisticated visualization libraries and predictive modeling frameworks, construction safety managers can now identify high-risk scenarios days or even weeks before they develop into critical situations. The integration of real-time sensor data with predictive analytics creates a dynamic safety ecosystem that continuously learns and adapts to evolving site conditions, marking a paradigm shift in construction risk management.

How AI-Powered Predictive Analytics Revolutionizes Construction Safety

Real-time Risk Assessment Capabilities

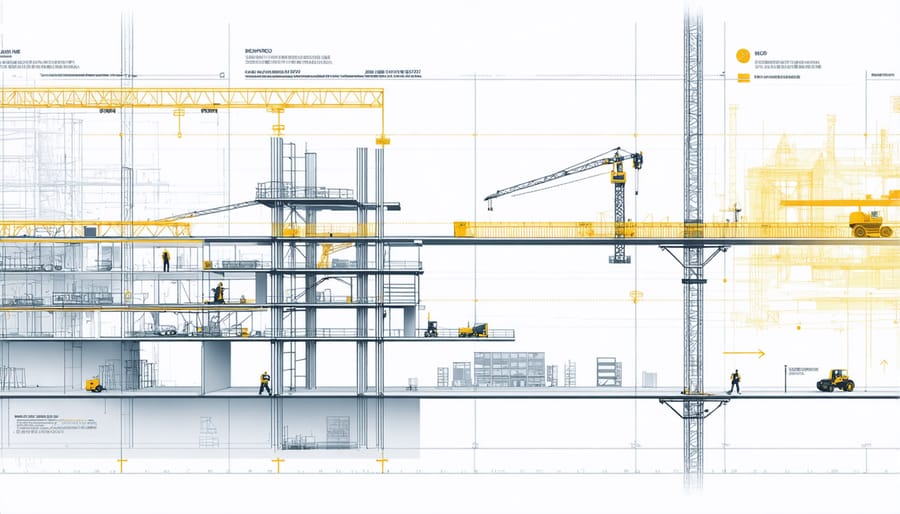

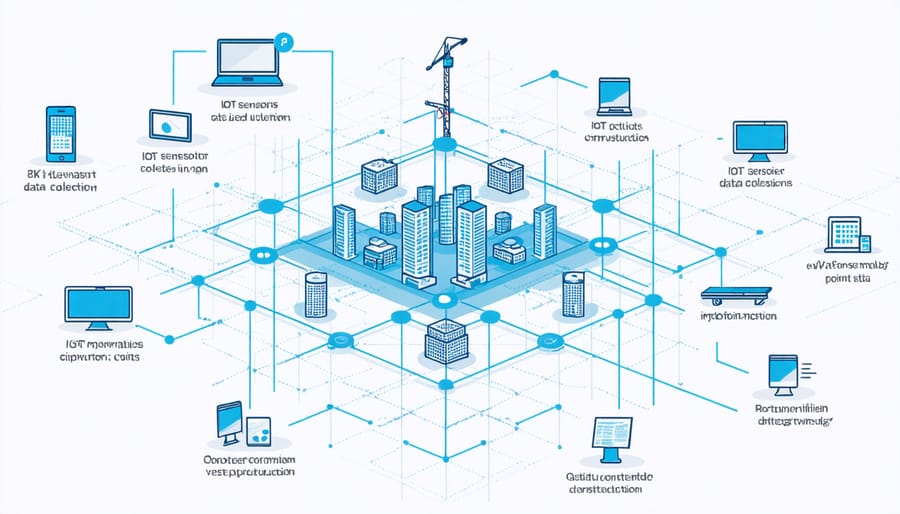

Modern AI-powered predictive analysis systems have revolutionized how construction sites monitor and assess risks in real-time. These advanced safety technologies in construction utilize an interconnected network of IoT sensors, cameras, and environmental monitoring devices to continuously gather data from multiple site locations simultaneously.

The system processes this data through sophisticated algorithms that can identify potential hazards before they escalate into incidents. For instance, when multiple risk factors converge – such as adverse weather conditions, equipment proximity, and worker concentration in high-risk zones – the AI system immediately alerts site managers through mobile applications and control center dashboards.

These real-time capabilities extend beyond simple alert systems. The AI continuously learns from new data, improving its prediction accuracy over time. It can detect subtle patterns that might escape human observation, such as gradual changes in structural stability or emerging workflow bottlenecks that could compromise safety. This proactive approach enables construction teams to implement preventive measures promptly, significantly reducing the likelihood of accidents and maintaining optimal site safety conditions.

Pattern Recognition in Safety Incidents

Artificial Intelligence excels at identifying subtle patterns in safety incident data that might escape human observation. By analyzing thousands of incident reports, near-misses, and safety observations, AI algorithms can detect recurring hazards and predict potential accident scenarios before they materialize. These systems process multiple data points simultaneously, including weather conditions, time of day, worker experience levels, and equipment usage patterns.

For example, AI analysis might reveal that falls from heights occur more frequently during specific weather conditions or that equipment-related incidents spike during certain shift changes. The system can identify complex correlations, such as how worker fatigue patterns combine with specific tasks to increase risk levels.

Construction companies implementing these pattern recognition systems report up to 30% reduction in recurring incidents. The technology continuously learns from new data, improving its predictive accuracy over time. When integrated with real-time monitoring systems, these AI tools can alert site managers to developing risk scenarios, enabling proactive intervention rather than reactive response.

This systematic approach to pattern recognition transforms vast amounts of historical safety data into actionable insights, creating a more robust and predictive safety culture on construction sites.

Key Components of AI Safety Analytics Systems

Data Collection Infrastructure

Modern construction sites are increasingly equipped with sophisticated data collection infrastructure that forms the foundation of predictive analysis capabilities. Advanced sensor networks monitor key environmental conditions, including temperature, humidity, vibration levels, and structural stress points. These sensors, often integrated into wearable devices worn by workers, continuously gather real-time data about worker movements, location tracking, and vital signs.

IoT-enabled equipment and machinery feature embedded sensors that monitor operational parameters, maintenance needs, and usage patterns. Smart cameras with computer vision capabilities capture visual data streams, while environmental monitoring stations track air quality, noise levels, and weather conditions that could impact site safety.

Data gathering methods extend beyond physical sensors to include digital platforms that collect project documentation, safety reports, and workflow data. Building Information Modeling (BIM) systems integrate with these data collection points, creating a comprehensive digital ecosystem. Mobile applications enable workers to report safety concerns and near-misses instantly, while automated check-in systems track site access and worker presence.

The infrastructure typically includes edge computing devices for initial data processing and robust networking solutions to ensure reliable data transmission. Cloud-based storage systems securely maintain historical data, enabling long-term trend analysis and pattern recognition. This comprehensive data collection framework provides the raw material necessary for meaningful predictive analysis, allowing construction teams to anticipate and prevent safety incidents before they occur.

Machine Learning Models and Algorithms

Several machine learning models play crucial roles in construction risk prediction, each offering unique capabilities for different aspects of safety analysis. Supervised learning algorithms, particularly Random Forests and Support Vector Machines (SVMs), excel at identifying patterns in historical incident data and predicting potential safety hazards. These models analyze multiple variables simultaneously, including weather conditions, worker behavior patterns, and equipment usage statistics.

Deep learning neural networks have shown remarkable accuracy in processing visual data from construction sites, enabling real-time threat detection through surveillance systems. These networks can identify unsafe practices, missing personal protective equipment (PPE), and potential hazard zones with increasing precision as they learn from new data.

The implementation of quantitative safety analytics has been enhanced by gradient boosting algorithms, which excel at processing time-series data to forecast risk levels across different project phases. These models can predict incident likelihood with up to 85% accuracy when properly trained with quality historical data.

Reinforcement learning algorithms are emerging as valuable tools for optimizing safety protocols, continuously adapting to new information and changing site conditions. These systems learn from both successful and unsuccessful safety interventions, gradually improving their recommendation accuracy for risk mitigation strategies.

For maximum effectiveness, many construction firms are adopting ensemble approaches, combining multiple algorithms to create more robust prediction systems that compensate for individual model limitations while leveraging their respective strengths.

Implementation Success Stories

Several leading construction companies have demonstrated remarkable success in implementing AI-driven predictive analytics for safety management. Skanska USA, for instance, achieved a 40% reduction in reportable incidents within 18 months of deploying a machine learning system that analyzed historical safety data and real-time site conditions.

Turner Construction implemented a comprehensive predictive analytics platform in 2021, which combines data from wearable devices, environmental sensors, and project management software. The system successfully identified high-risk situations 85% of the time, allowing supervisors to intervene before incidents occurred. This resulted in a 30% decrease in near-misses and a 25% reduction in workplace injuries across their projects.

Australian construction giant Lendlease deployed an AI-powered risk assessment tool across their Asia-Pacific operations. The system analyzed patterns from thousands of past incidents, weather conditions, and worker behavior data. Within the first year, they reported a 60% improvement in early risk detection and a 45% reduction in serious safety violations.

A medium-sized contractor in California, Bradford Construction, demonstrates that smaller companies can also benefit from predictive analytics. Their implementation of a cloud-based safety analytics platform helped identify potential fall hazards with 90% accuracy. The system’s predictive capabilities led to a 50% reduction in fall-related incidents and a 35% decrease in insurance premiums.

McCarthy Building Companies utilized machine learning algorithms to analyze their safety inspection data, equipment maintenance records, and worker certification status. The system’s predictive capabilities helped them prevent an estimated dozen serious incidents in 2022, resulting in significant cost savings and improved worker confidence in safety protocols.

These success stories highlight how predictive analytics can deliver tangible safety improvements across different construction environments and company sizes. The key success factors included comprehensive data collection, commitment to implementation, and integration with existing safety protocols.

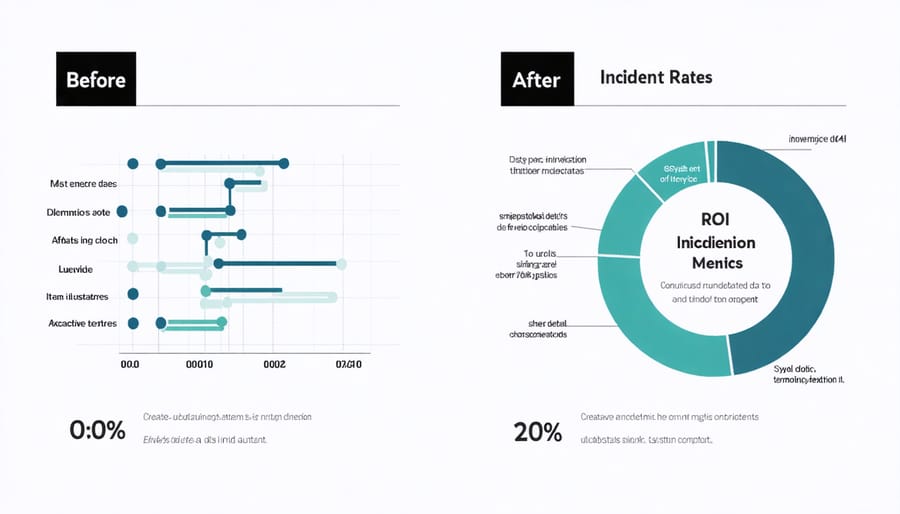

Measuring ROI and Safety Improvements

Quantifying the impact of predictive analytics on construction safety requires a comprehensive analysis of both financial returns and safety metrics. Recent industry studies indicate that construction companies implementing predictive analytics solutions typically achieve a risk management ROI of 3:1 to 5:1 within the first year of implementation.

Key performance indicators (KPIs) commonly used to measure effectiveness include incident rate reduction, near-miss reporting improvements, and workers’ compensation cost savings. Data from leading construction firms shows an average 25-35% reduction in recordable incidents after implementing predictive analytics systems, with some organizations reporting up to 50% fewer severe accidents.

Financial benefits manifest through multiple channels:

– Reduced insurance premiums (typically 15-20% reduction)

– Decreased project delays due to safety incidents

– Lower workers’ compensation costs

– Minimized equipment damage and repair expenses

– Reduced legal and compliance-related costs

Safety improvements can be measured through:

– Incident frequency rates (IFR)

– Lost time injury frequency rates (LTIFR)

– Total recordable injury frequency rates (TRIFR)

– Near-miss reporting rates

– Safety inspection compliance scores

Case studies from major construction projects demonstrate that predictive analytics systems can identify potential hazards 48-72 hours before they might occur, allowing for proactive intervention. This early warning capability has resulted in documented savings of $3-5 million annually for large-scale construction operations through accident prevention alone.

The most successful implementations show improved leading indicators within 3-6 months, including increased hazard reporting, better safety meeting attendance, and enhanced toolbox talk participation. These improvements correlate strongly with lagging indicators such as reduced incident rates and lower severity of accidents when they do occur.

AI predictive analytics represents a transformative force in construction safety management, revolutionizing how the industry approaches risk mitigation and accident prevention. By leveraging machine learning algorithms and real-time data analysis, construction companies can now proactively identify potential hazards before they materialize into incidents. The technology has demonstrated significant improvements in safety metrics, with early adopters reporting up to 50% reduction in workplace accidents and near-misses. Looking ahead, the integration of more sophisticated sensors, wearable technology, and advanced AI models promises even greater precision in risk prediction. As the construction industry continues to embrace digital transformation, AI-driven predictive analytics will become an indispensable tool for safety management, ultimately fostering safer work environments and protecting our most valuable asset – the workforce. The future of construction safety lies in the intelligent application of these predictive technologies, supported by proper training and implementation strategies.