In an era where energy costs and environmental impact drive construction decisions, energy-efficient materials have become the cornerstone of modern energy-efficient building practices. These innovative materials, from advanced insulation systems to smart glazing technologies, are revolutionizing how we approach sustainable construction while delivering substantial operational cost savings.

Recent advancements in material science have produced building components that not only minimize energy consumption but also enhance structural performance and occupant comfort. Phase-change materials, aerogel insulation, and self-regulating building envelopes represent just the beginning of a transformation in construction technology that promises to reshape our built environment.

For construction professionals and project stakeholders, understanding and implementing these materials has become crucial for meeting increasingly stringent energy codes and growing client demands for sustainable solutions. The strategic selection and application of energy-efficient materials can reduce building energy consumption by up to 70%, while simultaneously improving asset value and environmental performance.

This comprehensive guide explores cutting-edge materials, their applications, and the tangible benefits they offer to modern construction projects, providing essential insights for industry professionals committed to building a more sustainable future.

High-Performance Insulation Materials

Aerogel-Based Solutions

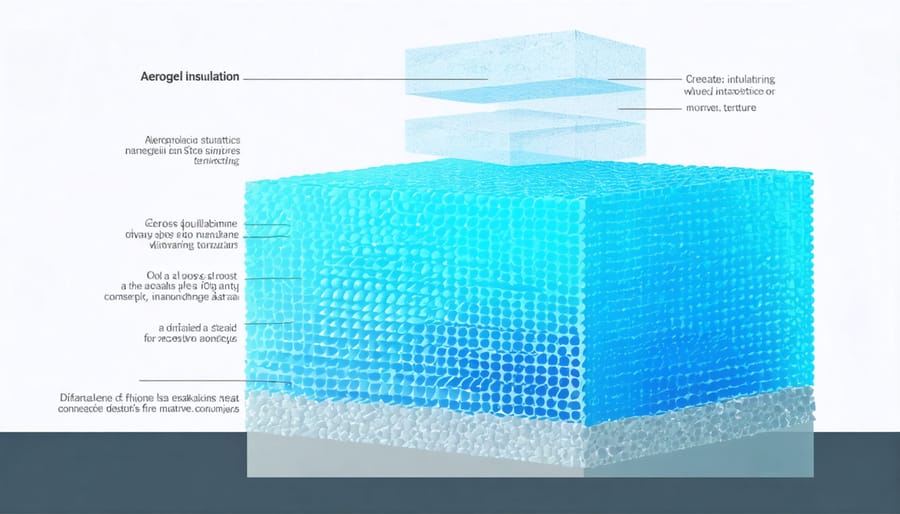

Among the most innovative advanced insulation technologies, aerogel-based solutions represent a groundbreaking advancement in thermal efficiency. Composed of up to 99.8% air, these ultra-lightweight materials achieve remarkable insulation performance with minimal thickness, typically offering thermal conductivity values as low as 0.015 W/mK.

In commercial construction, aerogel blankets and panels are revolutionizing building envelope design. Their superior thermal resistance allows architects to maximize usable floor space while meeting stringent energy codes. A mere 10mm aerogel blanket can provide the same insulation value as 30mm of traditional materials, making them particularly valuable in retrofit projects where space is at a premium.

Recent implementations in high-performance buildings have demonstrated energy savings of up to 30% compared to conventional insulation systems. The material’s hydrophobic properties also provide excellent moisture resistance, reducing the risk of thermal bridging and maintaining consistent performance throughout the building’s lifecycle.

Despite higher initial costs, aerogel solutions are increasingly adopted in premium construction projects where space optimization and energy efficiency are paramount. Their durability and long-term performance make them a cost-effective choice when considering the total lifecycle cost of the building envelope.

Phase Change Materials (PCMs)

Phase Change Materials (PCMs) represent a significant advancement in thermal energy storage technology, offering innovative solutions for maintaining optimal building temperatures while reducing energy consumption. These materials work by absorbing or releasing heat during phase transitions, typically between solid and liquid states, at specific temperature thresholds.

PCMs are particularly effective in maintaining consistent indoor temperatures by absorbing excess heat during peak daytime temperatures and releasing it when temperatures drop. Common materials used include organic compounds like paraffin waxes, fatty acids, and salt hydrates, each selected based on their melting point and specific application requirements.

In building applications, PCMs can be integrated into various construction elements, including:

– Wall panels and drywall systems

– Concrete mixtures

– Ceiling tiles

– Window systems

– HVAC components

The implementation of PCMs has shown remarkable results in real-world applications. Studies indicate that buildings incorporating PCM systems can reduce heating and cooling energy consumption by 20-30% compared to conventional structures. This efficiency is particularly notable in climates with significant temperature fluctuations.

Key considerations for PCM selection include:

– Phase transition temperature range

– Latent heat capacity

– Long-term stability

– Cost-effectiveness

– Fire safety requirements

– Environmental impact

Modern PCM applications often utilize microencapsulation technology, which enhances material stability and simplifies integration into building materials while maintaining optimal thermal performance.

Smart Glazing Technologies

Electrochromic Glass

Electrochromic glass represents a significant advancement in energy-efficient building materials, offering dynamic control over solar heat gain and natural light transmission. This smart glass technology utilizes an electrochemical reaction to switch between transparent and tinted states in response to applied voltage, effectively managing building energy consumption throughout the day.

Recent studies indicate that buildings equipped with electrochromic glazing can reduce HVAC energy costs by 20-30% and lighting expenses by up to 60% compared to conventional glass installations. The technology works through multiple layers of specialized materials, including transparent conductors and an ion storage layer, which change their optical properties when electrically charged.

The primary advantage of electrochromic glass lies in its ability to automatically adjust to environmental conditions. During peak sunlight hours, the glass darkens to reduce solar heat gain and glare, while maintaining clear views during overcast conditions or when maximum daylight is desired. This dynamic response eliminates the need for traditional window treatments and reduces the building’s overall cooling load.

Implementation costs have decreased significantly in recent years, making electrochromic glass increasingly viable for commercial applications. Leading manufacturers now offer warranties of up to 10 years, ensuring long-term performance and reliability. Notable installations in corporate headquarters and educational facilities have demonstrated both the aesthetic appeal and practical benefits of this technology in achieving sustainable building objectives.

Low-E Coatings

Low-emissivity (Low-E) coatings represent a significant advancement in energy-efficient building materials, offering exceptional thermal performance through microscopically thin metallic layers applied to glass surfaces. These coatings effectively manage solar heat gain while maximizing visible light transmission, making them crucial for modern sustainable construction.

The primary function of Low-E coatings is to reflect long-wave infrared radiation while allowing short-wave radiation to pass through. This selective transmission process helps maintain indoor temperatures by reflecting heat back into the building during winter and blocking excessive heat gain during summer. Studies have shown that windows with Low-E coatings can reduce energy loss by 30-50% compared to traditional glass.

Two main types of Low-E coatings dominate the market: hard-coat (pyrolytic) and soft-coat (sputtered). Hard-coat applications occur during the glass manufacturing process, creating a durable surface ideal for single-pane applications. Soft-coat systems, while requiring sealed unit construction, offer superior performance with higher visible light transmission and better thermal efficiency.

Recent technological advances have introduced spectrally selective Low-E coatings, which provide even greater control over solar heat gain while maintaining optimal daylight levels. These sophisticated coatings are particularly valuable in commercial buildings where balanced light transmission and thermal performance are essential for occupant comfort and energy savings.

Building professionals should consider climate zone, building orientation, and specific performance requirements when selecting Low-E coatings to achieve optimal energy efficiency outcomes.

Advanced Building Envelope Materials

Cool Roofing Solutions

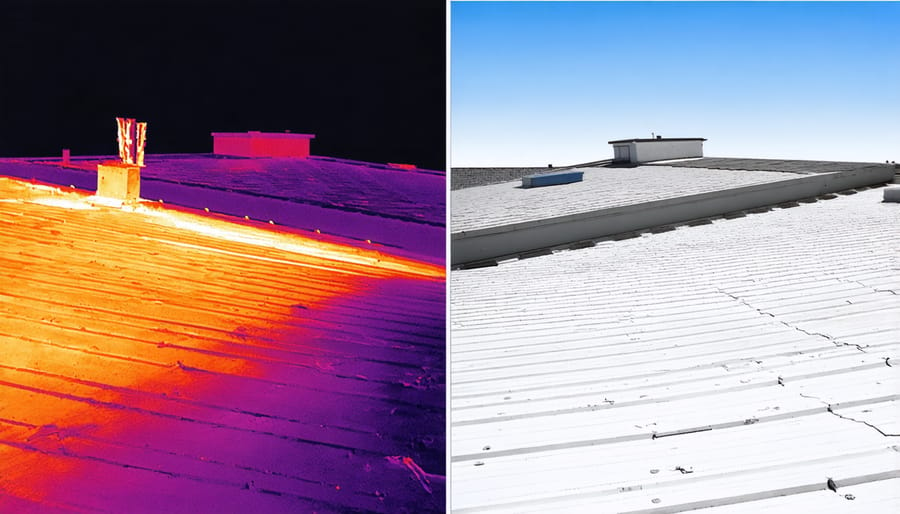

Cool roofing solutions represent a significant advancement in building energy efficiency, offering substantial thermal performance benefits through innovative material technology. These specialized roofing materials are engineered to reflect more sunlight and absorb less heat than conventional roofing surfaces, effectively reducing cooling costs and urban heat island effects.

High-performance cool roofs typically incorporate materials with enhanced solar reflectance index (SRI) values, including modified bitumen, single-ply membranes, and specialized roof coatings. White or light-colored thermoplastic polyolefin (TPO) membranes, for instance, can reflect up to 85% of solar radiation while maintaining durability and weather resistance. Similarly, polyvinyl chloride (PVC) roofing systems offer excellent reflective properties while providing superior waterproofing capabilities.

Recent developments in cool roof technology have introduced advanced ceramic coatings and infrared-reflective pigments that maintain high reflectivity even in darker colors, addressing aesthetic concerns while delivering energy-saving benefits. These materials can reduce roof surface temperatures by up to 50°F (28°C) compared to traditional roofing materials, resulting in potential energy savings of 10-30% on cooling costs.

Building professionals should consider several factors when selecting cool roofing solutions, including:

– Climate zone and local weather patterns

– Building type and usage requirements

– Initial cost versus long-term energy savings

– Local building codes and energy regulations

– Maintenance requirements and life expectancy

Implementation of cool roofing solutions has demonstrated significant returns on investment, particularly in commercial buildings with large roof areas. Studies have shown that these materials can extend roof life by reducing thermal stress and potentially decrease peak cooling demand by 10-15% in commercial applications.

High-Performance Wall Systems

High-performance wall systems represent a critical advancement in energy-efficient construction, combining innovative materials and sophisticated assembly techniques to maximize thermal performance and minimize energy loss. Modern wall systems typically incorporate multiple layers, each serving a specific function in the building envelope’s overall performance.

Structural Insulated Panels (SIPs) have emerged as a leading solution, offering superior thermal resistance with R-values ranging from R-14 to R-28. These prefabricated panels, consisting of an insulating foam core sandwiched between two structural boards, provide exceptional air-tightness and reduced thermal bridging compared to traditional stick-frame construction.

Advanced framing techniques, such as double-wall construction and continuous exterior insulation, have revolutionized thermal performance. Double-wall systems create a wider cavity for increased insulation while minimizing thermal bridging through the structural members. When combined with high-performance insulation materials like closed-cell spray foam or mineral wool, these systems can achieve R-values exceeding R-40.

Phase Change Materials (PCMs) represent the cutting edge of wall system technology. These materials absorb and release thermal energy during phase transitions, helping regulate indoor temperatures and reduce heating and cooling loads. Integration of PCMs into wall assemblies has shown energy savings of up to 25% in various climate zones.

Vapor-permeable air barriers and smart membranes have also transformed wall system performance. These materials allow controlled moisture migration while maintaining air-tightness, crucial for both energy efficiency and building durability. Modern air barriers can achieve air leakage rates as low as 0.05 L/s·m² at 75 Pa, significantly exceeding standard building code requirements.

Implementation of these systems requires careful attention to detail during installation and proper integration with other building components to achieve optimal performance.

Real-World Implementation

Several noteworthy projects demonstrate the successful implementation of energy-efficient materials in modern construction. The Edge building in Amsterdam stands as a prime example, achieving the highest BREEAM sustainability score ever recorded. This structure utilizes smart glass windows, solar panels, and advanced insulation materials, resulting in a 70% reduction in energy consumption compared to typical office buildings.

In Singapore, the Zero Energy Building at BCA Academy showcases the integration of multiple energy-efficient solutions. The building employs phase-change materials in its walls, which absorb excess heat during the day and release it at night, reducing cooling loads by approximately 30%. Additionally, its high-performance glass facade reflects solar heat while maximizing natural light penetration.

The Bullitt Center in Seattle demonstrates the practical application of energy-efficient building envelope systems. Its triple-paned windows, heavily insulated walls (R-40), and roof (R-60) work together to minimize heat transfer. The building operates at 82% less energy than comparable commercial structures, proving the effectiveness of these materials in real-world conditions.

A residential development in Stuttgart, Germany, implemented vacuum insulation panels (VIPs) in renovation projects, achieving thermal performance five to ten times better than conventional insulation materials. The project reported a 60% reduction in heating energy consumption while maintaining the original building’s architectural character.

The Crystal building in London combines multiple energy-efficient materials, including electrochromic glazing and advanced composite insulation. This integration results in 46% less energy consumption than comparable buildings. The structure serves as a living laboratory, providing valuable data on the long-term performance of these materials under real operating conditions.

These implementations demonstrate that energy-efficient materials, when properly selected and installed, can significantly reduce energy consumption while maintaining or improving building functionality. The success of these projects has influenced building codes and standards worldwide, driving wider adoption of energy-efficient materials in construction.

The evolution of energy-efficient materials continues to reshape the construction industry, offering increasingly sophisticated solutions for sustainable building practices. As demonstrated throughout this discussion, these materials play a pivotal role in reducing energy consumption, lowering operational costs, and minimizing environmental impact across various construction applications.

The integration of advanced insulation materials, smart windows, phase change materials, and innovative building envelope solutions has proven instrumental in achieving superior energy performance. Industry data consistently shows that buildings incorporating these materials achieve 30-50% better energy efficiency compared to conventional structures, while also providing enhanced occupant comfort and reduced carbon emissions.

Looking ahead, the future of energy-efficient materials appears promising, with emerging technologies such as aerogels, transparent wood composites, and self-healing materials poised to further revolutionize sustainable construction. Research and development efforts are increasingly focused on creating materials that are not only energy-efficient but also cost-effective, durable, and easier to implement at scale.

For construction professionals, staying informed about these developments is crucial. The growing emphasis on green building certifications, stricter energy codes, and environmental regulations will continue to drive demand for energy-efficient materials. Success in future construction projects will largely depend on the strategic selection and implementation of these materials, balanced with project requirements and budget considerations.

As we move toward a more sustainable built environment, the role of energy-efficient materials will become increasingly central to construction industry practices, making them an essential consideration for all industry stakeholders.