Power storage solutions have become the cornerstone of modern construction, fundamentally transforming how buildings manage and distribute energy. As construction costs soar and environmental regulations tighten, innovative smart energy systems are revolutionizing project economics and operational efficiency. Advanced battery technologies, from lithium-ion installations to emerging solid-state solutions, now enable construction professionals to implement robust power management strategies that reduce grid dependency by up to 40%.

The integration of these storage solutions addresses three critical challenges in modern construction: peak load management, renewable energy integration, and emergency power reliability. With energy storage costs declining by approximately 13% annually, construction managers can now justify significant investments in comprehensive power storage infrastructure, delivering both immediate operational benefits and long-term cost advantages.

This technological evolution demands a thorough understanding of storage options, implementation strategies, and regulatory compliance to maximize return on investment while ensuring project success. As we examine the latest developments in power storage solutions, we’ll explore how these systems are reshaping construction practices and creating new opportunities for sustainable building operations.

Current Challenges in Construction Power Management

Peak Load Management

Peak load management represents a critical challenge in modern construction site power management, particularly during periods of high energy demand. These demand spikes typically occur during concrete pours, crane operations, or simultaneous use of multiple power tools, leading to significant cost implications and potential grid instability.

Industry data shows that peak demand charges can constitute up to 70% of a construction site’s electricity costs. Strategic power storage solutions help mitigate these challenges by providing instantaneous power during high-demand periods, effectively smoothing out consumption patterns and reducing strain on the primary power supply.

Advanced battery systems and hybrid power solutions enable construction managers to implement load-shifting strategies, drawing from stored power during peak periods instead of relying solely on grid power. This approach not only reduces operational costs but also ensures consistent power delivery for critical applications. By implementing intelligent load management systems, construction sites can achieve optimal power distribution while maintaining a stable power supply throughout various construction phases.

Grid Independence Requirements

Remote construction sites and facilities in areas with unreliable grid connections require robust power storage solutions to maintain continuous operations. These installations must meet specific performance criteria to ensure operational reliability and safety. Storage systems need to provide sufficient capacity for peak demand periods while maintaining enough reserve power for critical operations during extended outages.

For remote locations, the storage solution should support at least 48-72 hours of autonomous operation, accounting for essential equipment and safety systems. This requirement typically translates to storage systems rated between 50-200 kWh, depending on site specifications and load requirements. Integration with renewable energy sources, such as solar arrays or wind turbines, can extend operational autonomy and reduce dependency on fuel-based generators.

Backup power demands must address both short-term power quality issues and extended outage scenarios. Modern storage systems should feature rapid response times (under 20 milliseconds) for seamless power transition and maintain stable voltage regulation within ±5% of nominal values. Construction sites should implement redundant systems and regular capacity testing protocols to ensure reliable performance during critical operations.

Key considerations include scalability for future expansion, environmental protection ratings suitable for construction environments, and compatibility with existing power infrastructure.

Advanced Battery Technologies in Construction

Lithium-Ion Solutions

Lithium-ion technology has emerged as the cornerstone of modern power storage solutions in construction applications, offering an optimal balance of energy density, cycle life, and operational efficiency. These batteries typically achieve 85-95% round-trip efficiency, significantly outperforming traditional lead-acid alternatives.

In commercial construction projects, lithium-ion systems are increasingly deployed for peak shaving and demand response applications. A notable case study from the Thompson Center renovation project demonstrated how a 500kWh lithium-ion installation reduced peak demand charges by 32% while providing critical backup power capabilities.

The technology’s versatility extends to mobile construction applications, where lithium-ion batteries power everything from electric excavators to aerial work platforms. Modern lithium iron phosphate (LiFePO4) chemistries offer enhanced safety features and longer operational lifespans, typically guaranteeing 3,000-7,000 cycles at 80% depth of discharge.

Key considerations for construction implementations include:

– Operating temperature range (-20°C to 60°C)

– Scalable capacity from 10kWh to multiple MWh

– Integrated battery management systems (BMS)

– Rapid charging capabilities (80% in under an hour)

– Minimal maintenance requirements

While initial costs remain higher than traditional alternatives, lifecycle cost analysis reveals favorable total ownership costs, with many systems achieving ROI within 5-7 years through reduced operational expenses and enhanced grid independence. The technology’s declining cost curve, currently at approximately $137/kWh, continues to improve the economic proposition for construction applications.

Emerging Storage Technologies

The landscape of power storage technologies is rapidly evolving, introducing innovative solutions that promise to revolutionize how construction projects manage and store energy. Flow batteries represent a significant breakthrough, offering scalable storage capacity through their unique liquid electrolyte system. Unlike traditional batteries, flow batteries can be easily scaled by simply increasing the size of storage tanks, making them particularly suitable for large construction sites with varying power demands.

Solid-state batteries are emerging as another promising technology, featuring higher energy density and improved safety characteristics compared to conventional lithium-ion batteries. These batteries utilize solid electrolytes instead of liquid ones, eliminating the risk of leakage and reducing fire hazards – crucial considerations for construction site safety compliance.

Metal-air batteries are gaining attention for their potential to complement solar power generation systems. These batteries use abundant materials like zinc or aluminum, combined with atmospheric oxygen, to create cost-effective storage solutions. Their high energy density and relatively simple construction make them particularly attractive for temporary power installations at construction sites.

Hydrogen fuel cells coupled with storage systems are showing promise for heavy machinery applications. While currently more expensive than traditional solutions, their rapid refueling capability and zero-emission operation align with increasingly stringent environmental regulations in urban construction projects.

Advanced thermal storage systems are also emerging as viable options, particularly for climate control applications in new buildings. These systems store excess energy as heat in specialized materials, providing a sustainable solution for managing peak load demands during construction and subsequent building operation.

The integration of artificial intelligence and smart management systems with these emerging technologies is enhancing their efficiency and reliability, allowing for predictive maintenance and optimal power distribution across construction sites. As these technologies mature and costs decrease, they are expected to become standard components in construction power management strategies.

Integration Strategies for Construction Sites

System Sizing and Selection

Selecting the appropriate power storage system requires careful analysis of several critical factors. Begin by calculating your peak power demand, including both baseline and surge requirements. Industry standards recommend a 20% capacity buffer to account for unexpected demand spikes and system degradation over time.

For construction sites, evaluate daily power consumption patterns across different phases of construction. Consider seasonal variations, equipment schedules, and operational hours. A comprehensive load analysis should account for both essential and non-essential loads, enabling effective capacity planning and potential load shedding strategies.

Storage capacity requirements can be determined using the formula: Required Capacity (kWh) = Peak Load (kW) × Operating Hours × Safety Factor. The safety factor typically ranges from 1.2 to 1.5, depending on application criticality.

Key sizing considerations include:

– Duration of required backup power

– Available space for installation

– Environmental conditions

– Grid connection requirements

– Future expansion possibilities

– Budget constraints

For optimal system selection, consider the following metrics:

– Round-trip efficiency

– Cycle life expectancy

– Response time

– Operating temperature range

– Maintenance requirements

– Total cost of ownership

Consult with certified power system engineers for detailed site assessments and system specifications. Regular review of system performance data helps validate sizing decisions and identifies potential optimization opportunities.

Safety and Compliance Considerations

Safety and regulatory compliance are paramount when implementing power storage solutions in construction projects. All installations must adhere to the National Electrical Code (NEC) requirements, particularly Articles 480 and 706, which govern energy storage systems and battery installations. OSHA standards for electrical safety must also be strictly followed, including proper lockout/tagout procedures during maintenance.

Storage systems require specific ventilation parameters and thermal management controls to prevent overheating and maintain optimal operating conditions. Fire suppression systems must be installed according to NFPA 855 guidelines, with appropriate detection and containment measures in place. Regular monitoring of battery temperature, charge levels, and system performance is essential for early problem identification.

Personnel safety protocols include mandatory use of appropriate PPE, specialized training for maintenance staff, and clear emergency response procedures. Installation areas must be properly marked with warning signs and access restrictions. Documentation of safety procedures, maintenance schedules, and emergency protocols should be readily available and regularly updated.

Environmental considerations include proper disposal procedures for end-of-life components and compliance with hazardous materials regulations. Facilities must maintain spill containment measures and implement recycling programs for battery components. Regular safety audits and compliance reviews ensure ongoing adherence to evolving regulations and industry best practices.

Third-party certification from recognized testing laboratories is often required to verify system safety and compliance with relevant standards. This includes UL listings for components and overall system certification.

Cost-Benefit Analysis

Initial Investment vs Long-term Savings

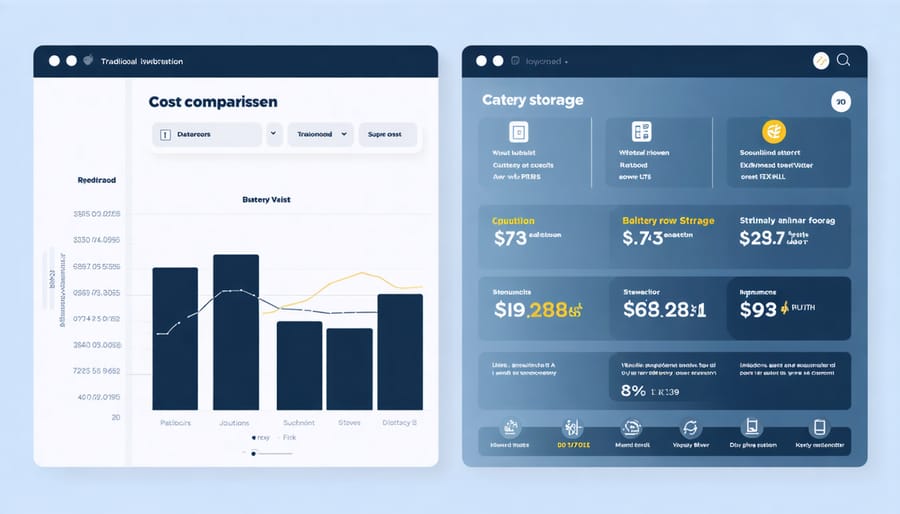

When evaluating power storage solutions, construction professionals must carefully weigh initial capital expenditure against long-term operational savings. Modern battery systems and energy storage installations typically require substantial upfront investment, ranging from $50,000 to $500,000 depending on capacity and sophistication. However, these systems consistently demonstrate strong return on investment through multiple revenue streams and cost reductions.

The primary financial benefits include peak demand reduction (20-30% savings on utility bills), energy arbitrage opportunities, and enhanced grid reliability. Additionally, when integrated with energy-efficient solutions, storage systems can reduce overall energy consumption by 15-25%.

Analysis of recent commercial installations shows ROI periods typically ranging from 4-7 years, with some high-usage facilities achieving payback in as little as 3 years. Factors affecting ROI include:

• Local utility rates and demand charges

• Available incentives and rebates

• System utilization rates

• Maintenance requirements

• Energy consumption patterns

Modern storage solutions also offer secondary financial benefits through improved power quality, reduced equipment wear, and enhanced operational reliability. When factoring in potential revenue from demand response programs and the rising costs of grid electricity, the long-term economic advantages become increasingly compelling for construction projects requiring stable, efficient power management.

Environmental Impact Benefits

Modern power storage solutions play a crucial role in reducing the construction industry’s environmental footprint through multiple pathways. Advanced battery systems and energy storage facilities significantly decrease reliance on fossil fuel-powered generators, leading to substantial reductions in carbon emissions during construction projects.

Studies demonstrate that implementing power storage solutions can reduce project-related carbon emissions by 30-45% compared to traditional power management methods. This reduction stems from optimized energy consumption patterns and the ability to store and utilize renewable energy sources effectively.

The integration of power storage systems enables construction sites to maximize their use of renewable energy sources, such as solar and wind power. By storing excess energy during peak production periods, these systems ensure consistent power availability while maintaining a smaller environmental impact. This capability is particularly valuable for remote construction sites that would otherwise depend entirely on diesel generators.

Beyond carbon reduction, modern storage solutions contribute to decreased noise pollution and improved air quality around construction sites. The elimination or reduction of constant generator operation results in healthier working conditions and better relationships with surrounding communities.

These systems also support the circular economy through their recyclable components and extended operational lifespans. Leading manufacturers now design storage units with up to 90% recyclable materials, while advanced battery management systems extend service life by up to 40% compared to previous generations.

As the construction industry continues to evolve, power storage solutions have become increasingly crucial for sustainable and efficient project execution. The integration of advanced battery systems, hybrid solutions, and smart grid technologies has revolutionized how construction sites manage and utilize energy resources. These innovations have not only improved operational efficiency but also significantly reduced environmental impact and operational costs.

The adoption of lithium-ion batteries, flow batteries, and hydrogen fuel cells demonstrates the industry’s commitment to embracing cleaner, more reliable power solutions. Case studies from major construction projects worldwide have shown that implementing modern storage systems can lead to 30-40% reduction in fuel consumption and up to 50% decrease in carbon emissions.

Looking ahead, the future of power storage in construction appears promising. Emerging technologies such as solid-state batteries and advanced thermal storage systems are expected to offer even greater efficiency and reliability. Industry experts predict that by 2030, most construction sites will operate with integrated power storage systems as standard practice.

For construction professionals, staying informed about these developments is essential. The transition to advanced power storage solutions requires careful planning, investment in appropriate infrastructure, and ongoing training for personnel. However, the long-term benefits – including reduced operational costs, improved project sustainability, and enhanced site safety – make this evolution not just beneficial but necessary for future success in the construction industry.