3D printing technology is revolutionizing the future of construction technology, fundamentally transforming how we design, build, and deliver construction projects. This advanced manufacturing method enables construction companies to reduce project timelines by up to 70% while cutting labor costs by 50-80% compared to traditional building methods. By depositing materials layer by layer with precision automation, 3D printing eliminates many of the inefficiencies and limitations inherent in conventional construction processes.

The technology’s impact extends beyond mere cost savings, offering unprecedented design freedom that allows architects to create complex geometric structures previously impossible or prohibitively expensive to build. From affordable housing solutions to high-end architectural innovations, 3D printing is proving to be a game-changing tool that addresses critical industry challenges such as labor shortages, material waste, and project delays.

As construction firms worldwide increasingly adopt this technology, understanding its core advantages becomes essential for industry professionals looking to maintain competitiveness and drive innovation in their projects. This analysis examines the key benefits that make 3D printing a transformative force in modern construction.

Cost Efficiency and Resource Optimization

Labor Cost Reduction

3D printing technology significantly reduces labor costs in construction projects by automating many traditionally manual processes. Studies indicate that 3D-printed buildings typically require only 2-3 skilled operators to manage the printing system, compared to 15-20 workers needed for conventional construction methods. This dramatic reduction in workforce requirements can lead to labor cost savings of up to 80% on specific project components.

The automation benefits extend beyond direct labor savings. By minimizing human intervention, 3D printing reduces errors and rework, which traditionally account for 10-15% of construction costs. The technology also eliminates the need for multiple specialized trades working sequentially, as the printer can handle various construction elements simultaneously.

Recent case studies demonstrate these savings in action. A residential project in Dubai reported a 50-60% reduction in labor costs through 3D printing implementation, while maintaining high quality standards. Additionally, the technology proves particularly valuable in regions experiencing skilled labor shortages or high labor costs, offering a viable solution for maintaining project momentum without escalating expenses.

The reduction in manual labor also translates to improved project scheduling, as 3D printing operations can continue 24/7 with minimal supervision, significantly accelerating construction timelines while keeping labor costs predictable and controlled.

Material Waste Minimization

3D printing technology in construction demonstrates remarkable efficiency in material usage, significantly reducing waste compared to traditional construction methods. By utilizing precise computer-controlled deposition, the technology deposits exactly the amount of material needed for each component, eliminating excess material consumption common in conventional construction processes.

Studies indicate that 3D printing can reduce material waste by up to 30-60% compared to traditional construction methods. This efficiency is achieved through detailed digital modeling that calculates exact material requirements before printing begins, ensuring optimal resource utilization. The technology’s ability to create hollow internal structures and optimize material density further contributes to waste reduction.

Additionally, many 3D printing materials can be recycled and reused in future projects, creating a more sustainable construction cycle. The precise nature of the printing process also minimizes common issues like over-ordering of materials and on-site cutting waste. This not only reduces environmental impact but also translates to significant cost savings for construction projects.

Construction companies implementing 3D printing report substantial reductions in material storage requirements and disposal costs, while maintaining structural integrity and quality standards.

Project Timeline Acceleration

3D printing technology significantly accelerates construction timelines by reducing manual labor requirements and streamlining the building process. Projects that traditionally take months can often be completed in weeks, with some residential structures being printed in as little as 24-48 hours. This dramatic reduction in construction time translates to substantial cost savings, with studies indicating up to 30% reduction in overall project duration.

The financial benefits extend beyond direct labor costs. Faster project completion means earlier occupancy, quicker return on investment, and reduced carrying costs such as equipment rentals and site management expenses. Additionally, the precision of 3D printing minimizes material waste and rework, further optimizing the construction schedule.

Case studies demonstrate that weather-related delays are also significantly reduced, as 3D printing operations can continue in various environmental conditions with minimal interruption, providing greater schedule reliability and predictability for project stakeholders.

Design Freedom and Architectural Innovation

Complex Geometries Made Simple

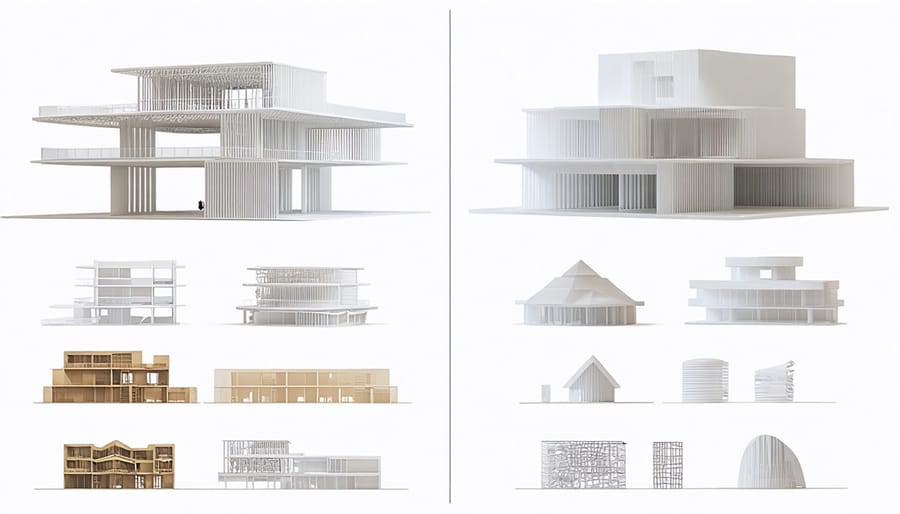

3D printing technology has revolutionized the way architects and construction professionals approach complex geometric designs. Traditional construction methods often struggle with intricate architectural elements, requiring extensive formwork, specialized labor, and significant time investment. However, 3D printing enables the creation of curved walls, organic shapes, and complex structural elements with remarkable precision and efficiency.

The technology’s layer-by-layer construction process allows for the realization of designs that would be prohibitively expensive or technically unfeasible using conventional methods. Double-curvature walls, honeycomb structures, and biomimetic patterns can be printed directly from digital models, eliminating the need for elaborate molds or complex assembly procedures.

Notable examples include the Office of the Future in Dubai, featuring fluid geometric forms, and the TECLA house in Italy, showcasing organically curved walls and domed structures. These projects demonstrate how 3D printing accommodates sophisticated architectural visions while maintaining structural integrity.

The precision of 3D printing also enables the integration of functional elements within complex geometries, such as built-in insulation channels, electrical conduits, and plumbing systems. This capability not only streamlines construction but also enhances building performance through optimized design features that would be challenging to implement using traditional methods.

Customization and Flexibility

One of the most compelling advantages of 3D printing in construction is its unparalleled ability to accommodate custom designs and architectural flexibility. This technology enables architects and designers to push creative boundaries while working with innovative construction materials to create complex geometries that would be prohibitively expensive or impossible using traditional construction methods.

The digital nature of 3D printing allows for rapid design iterations and modifications without incurring significant additional costs. Architects can easily adjust building features, incorporate unique structural elements, and customize spaces to meet specific client requirements. This flexibility extends to both aesthetic and functional aspects, from intricate façade patterns to optimized internal layouts that maximize space utilization.

Furthermore, 3D printing technology adapts seamlessly to site-specific requirements and local building codes. Construction teams can modify designs in real-time to accommodate unexpected site conditions or last-minute client requests. This adaptability proves particularly valuable in renovation projects where existing structures may present unique challenges requiring tailored solutions.

The technology also enables the creation of standardized components that can be customized for different applications, striking an optimal balance between mass production efficiency and personalization capabilities.

Environmental Impact and Sustainability

Carbon Footprint Reduction

3D printing technology represents a significant breakthrough in reducing construction carbon emissions through multiple pathways. Studies indicate that 3D-printed construction can reduce carbon footprint by up to 50% compared to traditional building methods, primarily through optimized material usage and reduced transportation requirements.

The precision of 3D printing eliminates excess material waste typically generated during conventional construction processes. By utilizing exact quantities of materials needed for each component, waste reduction can reach up to 30%, directly impacting the project’s environmental footprint. Furthermore, the ability to use recycled materials and locally sourced components in 3D printing mixtures contributes to sustainable construction practices.

Transportation-related emissions are significantly decreased as many components can be printed on-site, eliminating the need for extensive logistics chains. Research from the Construction Technology Institute shows that this can result in a 25% reduction in transportation-related carbon emissions.

The technology’s capacity for creating optimized geometric designs also contributes to environmental benefits. These structures can be designed with improved thermal efficiency, reducing long-term energy consumption and operational carbon emissions. Case studies demonstrate that 3D-printed buildings can achieve up to 20% better thermal performance compared to traditional constructions, leading to reduced heating and cooling requirements throughout the building’s lifecycle.

Advanced concrete mixtures developed specifically for 3D printing often incorporate sustainable materials like fly ash and slag, further reducing the environmental impact while maintaining structural integrity. This innovation in material science represents a crucial step toward more sustainable construction practices.

Sustainable Material Usage

3D printing in construction offers significant advantages in sustainable material usage, revolutionizing how the industry approaches environmental responsibility. The technology enables the precise calculation and deployment of materials, reducing waste by up to 30% compared to traditional construction methods. This optimization ensures that only the exact amount of material needed is used, minimizing environmental impact and resource consumption.

The technology accommodates a wide range of eco-friendly materials, including recycled concrete, bio-based composites, and sustainable polymers. Recent innovations have made it possible to incorporate recycled construction waste into printable materials, creating a circular economy within the construction sector. For instance, demolished concrete can be processed and reformulated into new printing materials, significantly reducing landfill waste.

Moreover, 3D printing technology allows for the integration of natural and locally sourced materials, reducing transportation emissions and supporting regional sustainability initiatives. Advanced material science has enabled the development of printable mixtures that incorporate industrial by-products like fly ash and slag, transforming waste materials into valuable construction resources.

The precision of 3D printing also enables the creation of optimized internal structures that use less material while maintaining structural integrity. These hollow or honeycomb-like patterns reduce material consumption while providing excellent insulation properties, contributing to both material efficiency and building energy performance. This approach not only conserves resources but also creates more sustainable, energy-efficient buildings for the future.

Safety and Quality Improvements

Workplace Safety Enhancement

One of the most significant benefits of 3D printing in construction is its potential to dramatically improve workplace safety. By implementing automated construction safety systems, companies can significantly reduce human exposure to hazardous conditions and high-risk activities typically associated with traditional construction methods.

The technology eliminates the need for workers to perform dangerous tasks at height, such as manual bricklaying on scaffolding or working on steep roof installations. 3D printing systems can operate continuously in challenging environments, including extreme weather conditions or hazardous sites, while keeping human operators at a safe distance in controlled environments.

Statistical data from early adopters indicates up to a 75% reduction in workplace accidents on sites utilizing 3D printing technology, particularly in high-risk activities like heavy material handling and working at elevations. The automation of these dangerous tasks not only protects workers but also helps construction companies maintain compliance with increasingly stringent safety regulations while reducing insurance costs and potential liability issues.

Moreover, the precision and consistency of 3D printing operations minimize the physical strain on workers, reducing the incidence of repetitive stress injuries and long-term occupational health issues common in traditional construction work.

Quality Control and Consistency

3D printing technology revolutionizes quality control in construction by offering unprecedented levels of precision and consistency throughout the building process. Computer-controlled systems ensure that each component is fabricated to exact specifications, with tolerances as precise as 1mm, significantly surpassing traditional construction methods.

The digital nature of 3D printing enables continuous monitoring and adjustment during production, eliminating human error and ensuring each element meets strict quality standards. This standardization extends across multiple projects, allowing contractors to maintain consistent quality regardless of location or scale.

Quality assurance is further enhanced through automated material testing and real-time monitoring systems. These systems verify material properties, layer adhesion, and structural integrity during the printing process, providing immediate feedback and allowing for instant corrections if needed.

The technology’s repeatability factor is particularly valuable for large-scale developments, where identical components must be produced in high volumes. This standardization not only improves overall build quality but also simplifies compliance with building codes and regulations, as each component can be precisely documented and verified against specified requirements.

Moreover, digital documentation of the printing process creates a comprehensive audit trail, enabling better quality management and facilitating future maintenance or modifications.

Structural Integrity

3D printing technology in construction delivers exceptional structural integrity through precise material layering and advanced computational design. Recent studies by the American Concrete Institute demonstrate that 3D-printed structures can achieve comparable or superior strength to traditional construction methods when properly engineered. The technology allows for optimized material distribution, creating internal support structures that would be impossible to achieve through conventional methods.

The layer-by-layer deposition process enables the integration of continuous reinforcement throughout the structure, eliminating weak points common in traditional construction joints. Advanced printing materials, including fiber-reinforced concrete and specialized polymer composites, further enhance structural performance. These materials can be precisely calibrated to meet specific load-bearing requirements and environmental conditions.

Testing has shown that 3D-printed walls exhibit excellent compression strength and dimensional stability. The controlled curing process and uniform material application result in fewer voids and better material bonding. This technological precision reduces the risk of structural defects and increases overall building durability. Additionally, the ability to create complex geometrical patterns internally allows for improved load distribution and enhanced seismic resistance, making 3D-printed structures particularly valuable in areas prone to natural disasters.

The integration of 3D printing technology in construction represents a transformative shift in how we approach building projects. As demonstrated throughout this analysis, the advantages are substantial and far-reaching. From significant cost reductions through optimized material usage and decreased labor requirements to unprecedented design freedom enabling complex architectural forms, 3D printing is revolutionizing traditional construction methodologies.

The environmental benefits are particularly noteworthy, with reduced waste generation, lower carbon emissions, and the potential for using recycled materials contributing to more sustainable construction practices. The technology’s ability to enhance worker safety by minimizing exposure to hazardous conditions while simultaneously increasing productivity presents a compelling case for wider adoption.

Looking ahead, the construction industry stands at the threshold of even greater innovation. As 3D printing technology continues to evolve, we can expect improvements in printing speeds, material diversity, and larger-scale applications. Industry experts predict that by 2030, 3D-printed structures could account for up to 30% of new construction projects in developed markets.

However, successful implementation will require continued investment in research and development, updates to building codes and regulations, and comprehensive training programs for construction professionals. Despite these challenges, the trajectory is clear: 3D printing technology is not just an alternative construction method but an essential tool for building a more efficient, sustainable, and innovative construction industry.