Industrial digital twins are revolutionizing construction and manufacturing by creating virtual replicas of physical assets, processes, and systems that mirror real-world conditions in real-time. These sophisticated digital models leverage IoT sensors, artificial intelligence, and advanced analytics to deliver unprecedented insights into operational performance, predictive maintenance, and process optimization.

Unlike traditional 3D models or simulations, industrial digital twins maintain a dynamic, two-way connection with their physical counterparts, enabling construction professionals to monitor, analyze, and optimize complex systems throughout their entire lifecycle. From design validation and construction monitoring to facility management and predictive maintenance, this technology transforms how projects are planned, executed, and maintained.

The impact of digital twins extends beyond technical capabilities—they’re becoming essential tools for risk mitigation, cost reduction, and strategic decision-making in construction projects. By providing a comprehensive digital representation of physical assets, these platforms enable stakeholders to identify potential issues before they occur, optimize resource allocation, and make data-driven decisions that significantly improve project outcomes.

As construction technology continues to evolve, industrial digital twins stand at the forefront of innovation, offering a powerful framework for integrating physical and digital worlds while delivering measurable returns on investment through enhanced efficiency, reduced downtime, and improved asset performance.

The Evolution of Digital Twin Technology in Construction

From BIM to Digital Twins

The evolution from traditional BIM modeling technologies to digital twins represents a significant leap in construction technology. While BIM provides a comprehensive 3D model of physical and functional characteristics, digital twins take this foundation several steps further by incorporating real-time data, IoT sensors, and advanced analytics capabilities.

This progression began with static 3D models and gradually incorporated 4D (time) and 5D (cost) dimensions. The transition to digital twins introduced dynamic data integration, enabling real-time monitoring and predictive capabilities. Modern digital twins can process continuous streams of information from multiple sources, including environmental sensors, structural monitoring systems, and building management systems.

The key differentiator lies in the bi-directional flow of information between the physical asset and its digital counterpart. Unlike traditional BIM models, digital twins can autonomously update themselves, reflect current conditions, and provide actionable insights for optimization and maintenance. This evolution has transformed static building models into living, breathing digital entities that mirror their physical counterparts with unprecedented accuracy.

Key Technologies Driving Industrial Digital Twins

The foundation of industrial digital twins rests on three key technological pillars: IoT sensors, artificial intelligence/machine learning (AI/ML), and advanced real-time data processing capabilities. IoT sensors form the nervous system of digital twin implementations, continuously collecting vital data about physical assets’ performance, environmental conditions, and operational parameters. These sensors monitor everything from structural integrity and temperature to vibration patterns and energy consumption.

AI and ML algorithms transform this raw sensor data into actionable insights, enabling predictive maintenance, performance optimization, and risk assessment. These systems can identify patterns and anomalies that would be impossible to detect through human observation alone, while also learning from historical data to improve accuracy over time.

Real-time data processing serves as the backbone of digital twin operations, utilizing edge computing and cloud infrastructure to handle massive data streams with minimal latency. This enables immediate response to critical situations and ensures that digital representations remain synchronized with their physical counterparts. Advanced visualization technologies, including AR and VR interfaces, then present this processed data in intuitive formats, allowing stakeholders to interact with and analyze complex systems effectively.

Core Components of Industrial Digital Twins

Real-time Data Collection Systems

Real-time data collection forms the backbone of industrial digital twins, primarily through sophisticated sensor networks and data gathering infrastructure. Modern construction projects leverage IoT sensors and analytics to continuously monitor critical parameters such as structural integrity, environmental conditions, and equipment performance.

These sensor networks typically comprise multiple layers of data collection points, including environmental sensors measuring temperature, humidity, and air quality; structural sensors monitoring strain, vibration, and displacement; and operational sensors tracking equipment usage, energy consumption, and material flow. The data is transmitted through secure wireless networks or hardwired connections to central processing systems.

Advanced data gathering infrastructure incorporates edge computing capabilities, allowing for preliminary data processing at the source. This approach reduces latency and bandwidth requirements while enabling real-time decision-making at the operational level. The system architecture typically includes redundant data collection pathways to ensure continuous monitoring even if individual sensors or communication channels fail.

Integration protocols such as MQTT (Message Queuing Telemetry Transport) and OPC UA (Open Platform Communications Unified Architecture) ensure seamless data flow between different systems and platforms. These standardized protocols facilitate interoperability between various sensors, controllers, and analytics platforms, creating a cohesive data ecosystem that powers the digital twin’s real-time capabilities.

Integration and Analysis Platforms

Integration and analysis platforms form the backbone of industrial digital twin implementations, serving as centralized hubs where vast amounts of sensor data, 3D models, and operational metrics converge. Leading platforms like Autodesk’s Tandem, Bentley’s iTwin, and Siemens’ Xcelerator combine real-time data processing capabilities with advanced analytics tools to transform raw data into actionable insights.

These platforms typically feature modular architectures that support various data inputs, including BIM models, IoT sensor feeds, and historical performance data. Key functionalities include real-time monitoring dashboards, predictive maintenance algorithms, and simulation capabilities that enable professionals to test scenarios before implementing changes in the physical environment.

Modern integration platforms emphasize interoperability, supporting standard data formats like IFC (Industry Foundation Classes) and API connections that enable seamless communication between different systems and software tools. Advanced analytics capabilities powered by machine learning algorithms help identify patterns, predict potential issues, and optimize operational parameters automatically.

Cloud-based deployment options have become increasingly popular, offering scalability and accessibility while reducing infrastructure costs. These platforms typically include robust security features, ensuring data integrity and protecting sensitive operational information. Many also provide collaboration tools that enable multiple stakeholders to work simultaneously with the digital twin data, fostering better communication and decision-making across project teams.

Practical Applications in Construction

Project Planning and Design Optimization

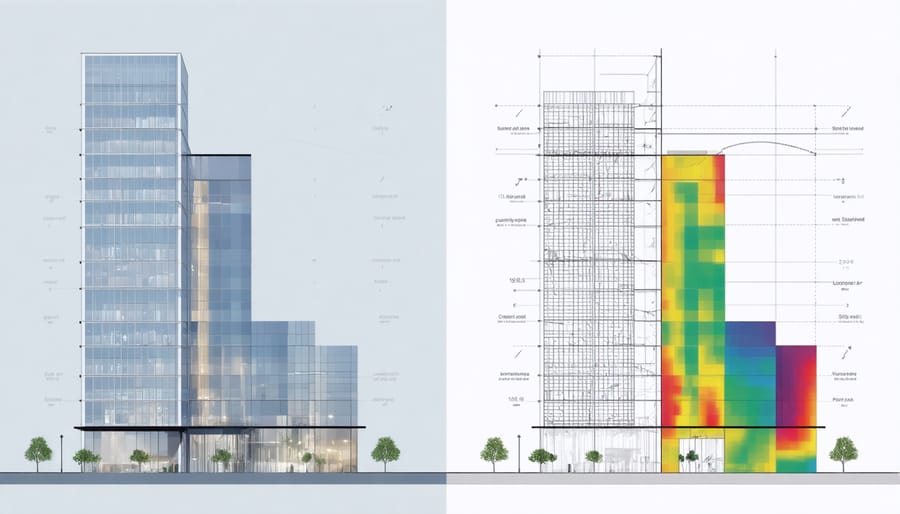

Digital twins are revolutionizing project planning and design optimization in industrial construction, offering unprecedented capabilities for decision-making and risk mitigation. By creating virtual replicas during the conceptual phase, stakeholders can evaluate multiple design scenarios and optimize layouts before breaking ground, significantly reducing costly modifications during construction.

The implementation of digital twins in smart buildings enables teams to conduct comprehensive feasibility studies, analyze structural integrity, and simulate various operational scenarios. This advanced modeling capability allows engineers to identify potential conflicts and inefficiencies early in the design process, leading to optimized space utilization and improved system integration.

Project managers can leverage digital twins to evaluate construction sequencing, resource allocation, and logistics planning. The technology facilitates real-time collaboration among stakeholders, enabling immediate feedback and rapid iteration of design solutions. This collaborative approach has demonstrated up to 30% reduction in design-related delays and a 25% decrease in construction rework costs.

Furthermore, digital twins support sustainable design practices by enabling detailed energy analysis and environmental impact assessments. Teams can simulate building performance under different conditions, optimize HVAC systems, and ensure compliance with environmental regulations before construction begins. This proactive approach to sustainability not only reduces environmental impact but also leads to significant operational cost savings over the building’s lifecycle.

The integration of digital twins in early project phases has proven particularly valuable for complex industrial facilities, where precise coordination of mechanical, electrical, and process systems is critical. Case studies have shown that early adoption of digital twin technology can result in 15-20% reduction in overall project costs and accelerate project delivery by up to 25%.

Construction Process Monitoring

Construction process monitoring through digital twins represents a transformative approach to project oversight and optimization. By creating a real-time virtual replica of the construction site, stakeholders can track progress, identify potential issues, and make informed decisions with unprecedented accuracy.

The system continuously collects data through an integrated network of IoT sensors, cameras, and scanning devices deployed across the construction site. This data feeds into the digital twin platform, providing real-time updates on various parameters including material usage, equipment utilization, worker productivity, and environmental conditions.

Project managers can monitor construction sequences and compare actual progress against planned schedules through detailed 4D visualizations. When deviations occur, the digital twin automatically flags these discrepancies, enabling quick response and adjustment of resources or schedules as needed.

One notable application is the automated progress tracking system, which uses computer vision and AI algorithms to analyze site imagery and update the digital model accordingly. This eliminates the need for manual progress reporting and reduces the risk of human error in documentation.

Safety monitoring is enhanced through real-time tracking of worker locations, equipment movement, and environmental hazards. The digital twin can trigger immediate alerts when safety protocols are breached or when potentially dangerous conditions are detected.

Quality control benefits significantly from this technology, as the digital twin can compare as-built conditions with design specifications in real-time. Dimensional accuracy, material placement, and installation procedures can be verified automatically, ensuring compliance with project requirements.

Resource optimization is achieved through predictive analytics that forecast material needs, equipment utilization, and labor requirements based on current progress and upcoming tasks. This capability helps prevent delays and reduces waste while maintaining optimal workflow efficiency.

ROI and Business Impact

Cost Savings and Efficiency Gains

The implementation of industrial digital twins delivers substantial cost savings and efficiency improvements across multiple operational areas. According to a recent McKinsey study, organizations using digital twin technology report an average reduction of 10-15% in maintenance costs and a 20% decrease in equipment downtime. These improvements directly translate to significant financial benefits, with some manufacturers reporting annual savings exceeding $2 million.

In construction projects, digital twins have demonstrated their value through enhanced resource optimization. A prominent European construction firm achieved a 25% reduction in material waste and a 30% improvement in equipment utilization after implementing digital twin technology. The real-time monitoring capabilities enabled predictive maintenance schedules, reducing unexpected downtime by 45% and extending equipment lifespan by up to 20%.

Energy efficiency gains are equally impressive, with digital twin implementations showing 15-30% reductions in energy consumption across industrial facilities. By simulating and optimizing operations in virtual environments before physical implementation, companies have reported reducing commissioning times by up to 40% and cutting project modification costs by 25%.

The technology’s impact on workforce productivity is notable, with staff efficiency increasing by up to 35% through improved decision-making and reduced response times. Additionally, quality control improvements facilitated by digital twins have led to a 30% reduction in defects and rework, significantly impacting project timelines and budgets.

Risk Mitigation and Quality Control

Digital twins serve as powerful tools for risk mitigation and quality control in industrial settings, offering real-time monitoring and predictive capabilities that fundamentally transform how projects are managed and executed. By creating virtual replicas of physical assets and processes, organizations can identify potential issues before they materialize, significantly reducing project risks and associated costs.

Through continuous data collection and analysis, digital twins enable project teams to simulate various scenarios and test different approaches without disrupting actual operations. This capability is particularly valuable in complex industrial environments where downtime can result in substantial financial losses. When integrated with AI-powered risk management systems, digital twins can automatically detect anomalies, predict equipment failures, and recommend preventive maintenance schedules.

Quality control benefits significantly from digital twin implementation, as these systems provide continuous validation of construction processes against design specifications. By comparing real-time data with predetermined quality standards, teams can quickly identify deviations and implement corrective measures. This proactive approach to quality management has been shown to reduce rework by up to 25% and improve first-time-right rates significantly.

Furthermore, digital twins enhance collaboration between stakeholders by providing a single source of truth for project status and performance metrics. This transparency helps align team efforts and ensures that quality standards are consistently met across all project phases.

Industrial digital twins represent a transformative force in construction, revolutionizing how projects are planned, executed, and maintained. Throughout this analysis, we’ve seen how this technology enables unprecedented levels of project visualization, real-time monitoring, and predictive maintenance capabilities. The integration of IoT sensors, AI algorithms, and advanced simulation tools has proven to deliver substantial improvements in project efficiency, risk management, and cost control.

Looking ahead, the construction industry can expect even more sophisticated applications of digital twin technology. Machine learning algorithms will become more refined, offering increasingly accurate predictions and insights. The convergence of 5G networks and edge computing will enable faster data processing and more responsive digital twin systems, while improvements in AR and VR technology will make these tools more accessible and user-friendly for on-site teams.

However, successful implementation requires careful consideration of infrastructure requirements, data security protocols, and staff training programs. Organizations must develop clear strategies for data management and system integration while ensuring their digital twin initiatives align with broader business objectives.

As construction projects become more complex and sustainability requirements more stringent, digital twins will play an increasingly crucial role in project delivery and asset management. Those who embrace this technology early and develop the necessary expertise will be better positioned to meet future industry challenges and capitalize on emerging opportunities in smart construction and sustainable building operations.