Supply chain risk assessment has become the cornerstone of construction project success in an increasingly volatile global market. Recent industry data reveals that 87% of construction firms experienced significant disruptions due to unforeseen supplier risks, resulting in project delays and cost overruns averaging $2.3 million per incident. Machine learning and advanced analytics now offer unprecedented capabilities to predict, identify, and mitigate supply chain vulnerabilities before they impact project timelines.

Construction executives and project managers must adopt a proactive approach to risk assessment, leveraging real-time data analytics to evaluate supplier financial stability, delivery performance, and compliance metrics. This systematic evaluation becomes particularly crucial when managing complex projects with multiple international suppliers and time-sensitive deliverables.

By implementing robust risk assessment frameworks, construction firms can transform traditional supplier management into a strategic advantage. Modern risk assessment protocols combine historical performance data, market intelligence, and predictive analytics to create a comprehensive risk profile for each supplier, enabling informed decision-making and contingency planning.

The integration of these advanced risk assessment methodologies has demonstrated a 65% reduction in supply chain disruptions and a 40% improvement in project delivery reliability among early adopters in the construction sector. This strategic approach to supplier risk management represents a fundamental shift in how construction firms ensure project success and maintain competitive advantage.

The Evolution of Supply Chain Risk Management in Construction

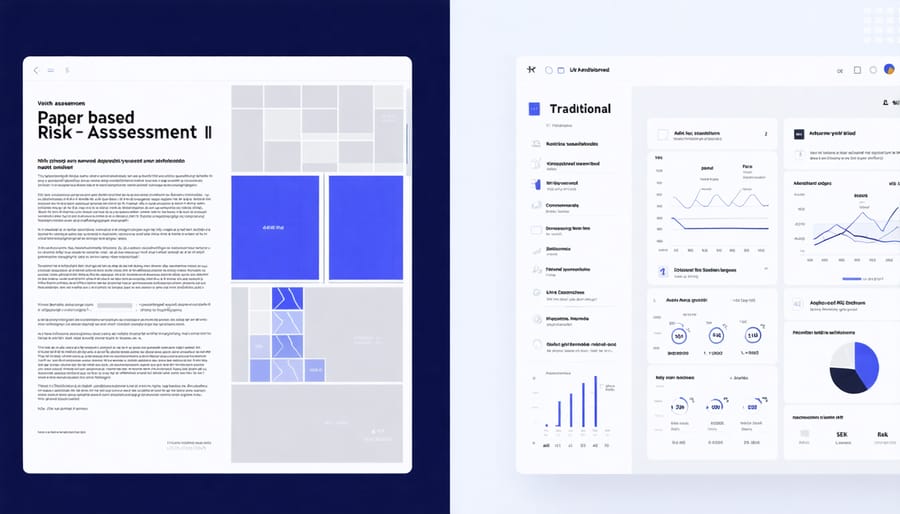

Traditional Risk Assessment Methods

Traditional risk assessment methods in construction supply chains typically rely on manual processes and historical data analysis. These approaches include vendor scorecards, financial statement reviews, and periodic performance evaluations. Procurement teams often use weighted scoring systems to evaluate suppliers based on criteria such as delivery reliability, quality metrics, and cost competitiveness.

However, these conventional methods have significant limitations in today’s complex construction environment. They often fail to capture real-time risks, rely heavily on lagging indicators, and struggle to process the vast amount of data generated by modern supply chains. Manual assessments can be time-consuming and prone to human bias, potentially missing critical risk signals.

Additionally, traditional methods typically operate in silos, focusing on individual supplier performance rather than understanding interconnected risks across the supply network. They may not adequately account for emerging risks such as cybersecurity threats, geopolitical issues, or environmental concerns that can significantly impact construction projects.

The static nature of these assessments also means they cannot quickly adapt to rapidly changing market conditions or provide predictive insights for proactive risk management.

The Machine Learning Revolution

Machine learning is revolutionizing how construction companies assess and manage supply chain risks. By leveraging advanced algorithms and predictive analytics, organizations can now process vast amounts of supplier data to identify potential risks before they materialize. This transformation has become particularly evident as more companies adopt digital procurement solutions that incorporate AI-driven risk assessment capabilities.

These intelligent systems can analyze multiple risk factors simultaneously, including supplier financial stability, delivery performance history, quality metrics, and market conditions. For construction projects, where timing and material quality are critical, ML algorithms can predict supplier delays, detect quality issues, and identify potential cost overruns with remarkable accuracy.

The technology’s ability to learn from historical data and adapt to new patterns makes it particularly valuable in today’s volatile construction market. By continuously monitoring and analyzing supplier performance metrics, ML systems provide real-time risk alerts and actionable insights, enabling project managers to make informed decisions quickly and implement mitigation strategies proactively.

Key ML Applications in Supplier Risk Assessment

Predictive Analytics for Supplier Performance

Modern construction supply chains leverage AI-powered predictive analytics to transform supplier performance assessment from reactive to proactive monitoring. These sophisticated systems analyze vast datasets, including historical delivery times, quality metrics, financial indicators, and market conditions to forecast potential supplier issues before they impact project timelines.

Machine learning algorithms evaluate patterns in supplier behavior, identifying early warning signs of performance degradation. Key performance indicators such as delivery consistency, material quality variance, and response times are continuously monitored and compared against established benchmarks. The system flags anomalies that might indicate impending supply chain disruptions.

Advanced predictive models incorporate external factors such as weather patterns, market volatility, and regional economic indicators to provide comprehensive risk assessments. For instance, these systems can predict the likelihood of material shortages by analyzing global supply trends and commodity prices, enabling construction firms to implement preventive measures proactively.

Real-time monitoring capabilities allow project managers to receive instant alerts when suppliers deviate from expected performance metrics. This early warning system enables swift intervention, whether through supplier engagement, alternative sourcing, or contingency plan activation. The technology’s ability to learn from historical data continuously improves prediction accuracy, making it an invaluable tool for modern construction supply chain management.

Real-time Risk Monitoring Systems

Modern construction supply chains demand continuous monitoring capabilities powered by machine learning algorithms that can process vast amounts of real-time data. These systems analyze multiple risk indicators simultaneously, from financial metrics to operational performance, enabling proactive risk management rather than reactive responses.

Advanced ML models can now track supplier performance across key parameters, including delivery times, quality metrics, and vendor cybersecurity risks. The systems employ predictive analytics to forecast potential disruptions before they materialize, allowing procurement teams to implement mitigation strategies proactively.

Real-time monitoring platforms typically integrate data from various sources, including:

– Supplier financial health indicators

– Geographic and political risk factors

– Weather and natural disaster predictions

– Market volatility metrics

– Quality control measurements

– Compliance and certification status

Construction firms implementing these systems report significant improvements in risk prediction accuracy, with some achieving up to 85% accuracy in forecasting supplier-related disruptions. The technology enables instant alerts when risk thresholds are exceeded, allowing procurement teams to quickly pivot to alternative suppliers or activate contingency plans.

These systems also facilitate better decision-making through comprehensive dashboards that visualize risk levels across the supply chain, helping managers prioritize their risk management efforts and allocate resources more effectively.

Financial Health Assessment

Machine learning algorithms have revolutionized how construction companies evaluate supplier financial stability, providing deeper insights and early warning systems for potential risks. These sophisticated tools analyze multiple financial indicators simultaneously, including liquidity ratios, debt levels, cash flow patterns, and payment histories to generate comprehensive risk scores.

Advanced ML models utilize both structured financial data and unstructured information, such as market news, regulatory filings, and industry trends, to predict potential financial distress up to 18 months in advance. This predictive capability enables construction firms to take proactive measures before supplier financial issues impact project timelines.

Key financial metrics these algorithms monitor include:

– Working capital ratios

– Debt-to-equity relationships

– Account receivable turnover

– Operating margin trends

– Credit rating changes

The ML systems continuously learn from historical data, improving their accuracy in identifying warning signs specific to construction industry suppliers. For instance, seasonal fluctuations in material costs and project-based revenue patterns are factored into the analysis, providing context-aware risk assessments.

Real-time monitoring capabilities allow for immediate alerts when a supplier’s financial health indicators deviate from established thresholds. This enables procurement teams to implement contingency plans or negotiate additional safeguards before financial instability affects material delivery or quality.

Construction companies can customize these algorithms to align with their risk tolerance levels and specific supplier categories, ensuring focused monitoring of critical vendors while maintaining efficient resource allocation.

Implementation Strategies

Data Requirements and Collection

Effective risk assessment in construction supply chains requires comprehensive data collection across multiple dimensions. Key data points include supplier financial metrics, operational performance indicators, quality control records, and compliance documentation. Financial data should encompass credit ratings, payment history, and financial statements, while operational metrics must track delivery performance, production capacity, and response times.

Quality-related data points should include defect rates, warranty claims, and third-party certifications. Environmental, Social, and Governance (ESG) metrics have become increasingly crucial, requiring documentation of sustainability practices, labor conditions, and corporate governance structures.

Data collection methods typically combine automated systems with manual verification processes. Digital platforms can continuously monitor supplier performance through integrated Enterprise Resource Planning (ERP) systems, while third-party data providers offer real-time market intelligence and risk alerts. Regular supplier audits, site visits, and documentation reviews remain essential for validation.

Construction firms should establish standardized data collection protocols, including:

– Regular supplier self-assessment questionnaires

– Automated performance tracking systems

– Third-party verification reports

– Site inspection records

– Compliance documentation updates

– Historical performance data

– Market intelligence reports

The frequency of data collection should align with risk levels, with critical suppliers requiring more frequent monitoring. Implementation of secure data management systems ensures information accuracy and accessibility while maintaining confidentiality and compliance with data protection regulations.

Integration with Existing Systems

Integrating machine learning tools into existing supply chain risk assessment processes requires a methodical approach that minimizes disruption while maximizing efficiency. Begin by conducting a thorough audit of current systems and identifying integration points where digital construction tools can enhance decision-making capabilities.

Start with a pilot program focusing on a specific supplier segment or risk category. This allows teams to validate the ML system’s effectiveness while maintaining operational continuity. Ensure data compatibility by establishing standardized formats and protocols for information exchange between legacy systems and new ML platforms.

Implementation should follow a phased approach:

1. Data migration and cleansing

2. System configuration and customization

3. User training and documentation

4. Parallel running of old and new systems

5. Performance monitoring and adjustment

Critical success factors include securing stakeholder buy-in, providing comprehensive training programs, and establishing clear communication channels for feedback and support. Create detailed documentation of integration procedures and maintain regular system health checks to ensure optimal performance.

Consider implementing API connections to enable real-time data flow between systems, and establish automated validation protocols to maintain data integrity. Regular performance reviews and system optimization ensure the integrated solution continues to meet evolving risk assessment needs.

Case Study: ML Risk Assessment in Action

In 2021, Global Construction Enterprises (GCE), a leading commercial developer, implemented a machine learning-based risk assessment system to evaluate their supplier network across multiple projects in the Asia-Pacific region. The company had previously experienced significant delays and cost overruns due to supplier-related issues, prompting the need for a more sophisticated approach to risk management.

The ML system analyzed historical data from over 500 suppliers, including delivery times, quality metrics, financial stability indicators, and compliance records. By incorporating real-time market data and regional economic indicators, the system could predict potential supplier disruptions with 85% accuracy, compared to the previous manual assessment’s 60% accuracy rate.

Key implementation phases included:

1. Data Collection and Integration

– Consolidated supplier performance data from the past five years

– Integrated weather pattern data affecting material transportation

– Incorporated financial health indicators from third-party sources

– Gathered local regulatory compliance records

2. Risk Model Development

– Created custom algorithms for construction-specific risk factors

– Developed weighted scoring systems for different supplier categories

– Implemented dynamic threshold adjustments based on project requirements

The system’s early warning capabilities proved crucial during a cement supplier’s financial distress in Q3 2022. The ML model detected concerning patterns in the supplier’s payment behaviors and production outputs three months before conventional methods would have raised alerts. This early detection allowed GCE to secure alternative suppliers, preventing an estimated $2.8 million in potential project delays.

Results after 18 months of implementation:

– 32% reduction in supplier-related delays

– 24% decrease in emergency procurement costs

– 40% improvement in supplier performance monitoring efficiency

– 15% reduction in overall supply chain management costs

The success of this implementation led GCE to expand the system across their global operations, with particular emphasis on high-risk markets. The company also developed a supplier onboarding program that integrates directly with their ML risk assessment platform, ensuring consistent evaluation standards across all new partnerships.

This case demonstrates how ML-driven risk assessment can transform traditional supply chain management in construction, providing actionable insights and measurable improvements in operational efficiency.

Effective risk assessment in construction supply chains has become increasingly crucial for project success and organizational resilience. The integration of advanced analytics, machine learning, and real-time monitoring systems has transformed how companies identify, evaluate, and mitigate supplier risks. As the construction industry continues to evolve, we can expect further innovations in predictive modeling and automated risk scoring systems. Organizations that embrace these technological advances while maintaining strong supplier relationships will be better positioned to navigate future challenges. The outlook for supply chain risk assessment remains promising, with emerging technologies offering even greater capabilities for risk visualization, scenario planning, and proactive mitigation strategies. By implementing robust risk assessment frameworks today, construction companies can build more resilient supply chains that support sustainable growth and project success in an increasingly complex global market.