Digital transformation is revolutionizing the construction industry, driving unprecedented efficiency gains of up to 25% in project delivery times and cost reduction. By integrating cloud-based project management platforms, IoT sensors, and advanced analytics, construction firms are reimagining traditional workflows and achieving remarkable results in safety, productivity, and sustainability.

The construction sector stands at a critical inflection point where digital innovation isn’t just an option—it’s a competitive necessity. Leading firms leveraging Building Information Modeling (BIM), artificial intelligence, and connected job sites are reporting 20% improvements in project margins and 30% reductions in rework costs. This technological evolution transforms every aspect of construction operations, from initial design and planning to project execution and facility management.

As we witness this seismic shift, construction companies must embrace a holistic approach to digital transformation that encompasses people, processes, and technology. The integration of digital tools isn’t merely about adopting new software; it’s about fundamentally restructuring how construction projects are conceived, planned, and delivered. With global construction spending expected to reach $15.5 trillion by 2030, organizations that successfully navigate this digital revolution will define the industry’s future.

This transformative journey requires strategic vision, careful planning, and unwavering commitment to innovation. The most successful implementations start with clear objectives, involve all stakeholders, and focus on measurable outcomes that drive real business value.

The Digital Construction Ecosystem

Building Information Modeling (BIM) Integration

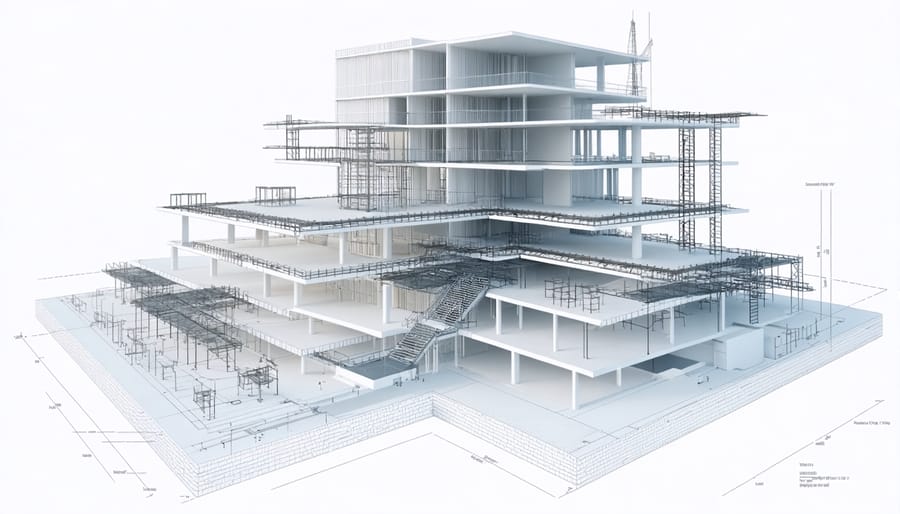

Building Information Modeling (BIM) serves as the cornerstone of digital transformation in construction, revolutionizing how projects are conceived, designed, and executed. As a comprehensive digital representation of physical and functional characteristics of buildings, BIM enables seamless collaboration across all project stakeholders. Successful BIM implementation strategies have demonstrated up to 25% reduction in project completion time and significant cost savings through improved coordination and clash detection.

The integration of BIM technology extends beyond traditional 3D modeling, incorporating crucial dimensions such as time (4D), cost (5D), and sustainability (6D). This multi-dimensional approach enables real-time visualization of project progress, accurate cost estimation, and efficient resource allocation. Leading construction firms are leveraging BIM’s capabilities for prefabrication, reducing on-site errors and accelerating construction schedules.

Data from recent industry surveys indicates that BIM adoption has increased by 71% over the past five years, with organizations reporting enhanced project delivery accuracy and improved stakeholder communication. The technology’s ability to facilitate virtual design and construction (VDC) processes has become particularly valuable in complex projects, where early detection of potential conflicts can save millions in rework costs and schedule delays. As the industry continues to evolve, BIM remains fundamental to achieving true digital transformation in construction operations.

Cloud-Based Project Management Platforms

Cloud-based project management platforms have revolutionized how construction teams collaborate and manage projects in real-time. These sophisticated systems integrate various project components, from document management to resource allocation, creating a centralized hub for all stakeholders.

Leading platforms like Procore, Autodesk Construction Cloud, and PlanGrid enable teams to access critical project information from any location, facilitating immediate decision-making and problem-solving. Project managers can monitor progress, track deliverables, and coordinate multiple teams simultaneously through intuitive dashboards and mobile applications.

These platforms excel in document control and version management, ensuring all team members work with the latest plans and specifications. Real-time updates and notifications keep stakeholders informed of changes, reducing errors and minimizing costly rework. The ability to maintain a complete audit trail of all project communications and decisions has become invaluable for risk management and compliance.

Cloud-based solutions also integrate seamlessly with other digital tools, including BIM software, scheduling applications, and financial management systems. This interoperability creates a comprehensive digital ecosystem that supports the entire project lifecycle.

According to recent industry studies, construction firms using cloud-based project management platforms report up to 35% improvement in project delivery times and a 25% reduction in documentation errors. The adoption of these platforms has become a crucial differentiator in maintaining competitiveness and ensuring project success in today’s digital construction landscape.

Real-Time Collaboration Technologies

Mobile Solutions for On-Site Teams

Mobile technology has revolutionized how construction teams operate on-site, enabling real-time decision-making and seamless communication between field workers and office staff. Through sophisticated mobile applications and digital collaboration platforms, teams can now access critical project information, submit reports, and resolve issues instantly from any location.

Modern mobile solutions typically incorporate features such as digital blueprints, BIM model viewers, progress tracking tools, and safety inspection checklists. Field personnel can capture and annotate photos, record measurements, and document site conditions using their smartphones or tablets, eliminating the need for paper-based processes and reducing the risk of data loss or miscommunication.

Real-world implementation has shown significant improvements in productivity. For example, Turner Construction reported a 33% reduction in documentation time after implementing mobile field solutions across their projects. These tools enable superintendents and foremen to spend more time supervising work rather than handling paperwork.

Key benefits of mobile solutions include:

– Immediate access to up-to-date project documents

– Real-time issue reporting and resolution

– Digital daily reports and time tracking

– Photo documentation with geo-tagging

– Quality control and safety inspection tools

– Material tracking and inventory management

To maximize the effectiveness of mobile solutions, construction companies should ensure proper training for field staff and establish clear protocols for data input and communication. Additionally, choosing mobile applications that integrate with existing project management systems helps maintain data consistency and promotes widespread adoption among team members.

Digital Twin Implementation

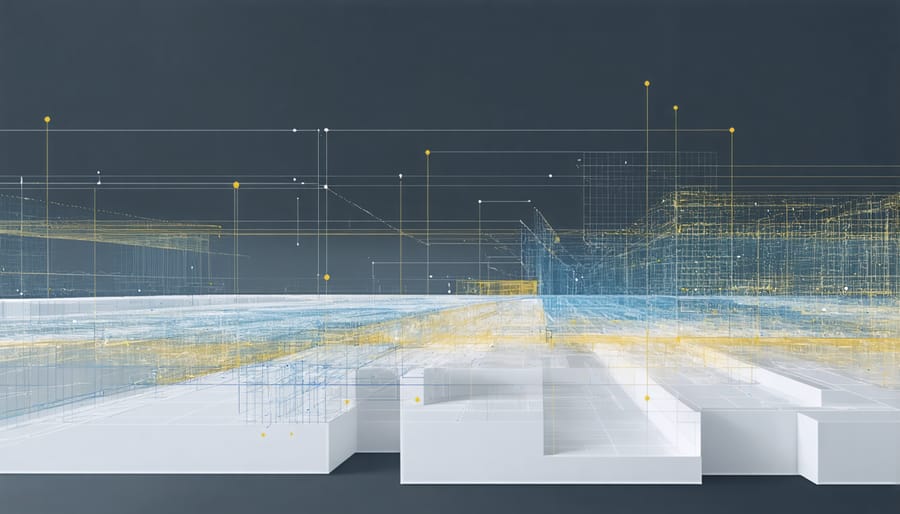

The implementation of digital twin technology in construction projects represents a significant advancement in project optimization and risk management. By creating precise virtual replicas of physical assets, construction teams can simulate, analyze, and optimize project outcomes before breaking ground.

The implementation process typically begins with data collection through IoT sensors, laser scanning, and photogrammetry to create accurate 3D models. These models are then enhanced with real-time data feeds, enabling continuous monitoring and analysis of project performance. Advanced software platforms integrate this information with building information modeling (BIM) systems, creating a comprehensive digital ecosystem.

Construction managers utilize these virtual models to conduct scenario planning, identify potential conflicts, and optimize resource allocation. For instance, teams can simulate various construction sequences to determine the most efficient build order, reducing project timelines and minimizing waste. The technology also enables precise coordination between different trades, significantly reducing on-site conflicts and rework.

Real-time monitoring capabilities allow project stakeholders to track construction progress against planned schedules, detect deviations early, and make data-driven decisions. Environmental sensors provide valuable insights into site conditions, material performance, and structural behavior, enhancing quality control and safety measures.

Furthermore, digital twins serve as powerful collaboration tools, enabling remote stakeholders to visualize and interact with project components in real-time. This capability has proven particularly valuable for complex projects involving multiple teams across different locations, facilitating improved communication and decision-making processes throughout the project lifecycle.

Data-Driven Decision Making

Predictive Analytics for Risk Management

Predictive analytics has emerged as a game-changing tool in construction risk management, leveraging historical project data, real-time sensor information, and advanced algorithms to forecast potential challenges before they materialize. By analyzing patterns from past projects, weather conditions, supply chain disruptions, and workforce performance metrics, construction firms can now anticipate and mitigate risks with unprecedented accuracy.

Modern risk management platforms integrate multiple data sources, including BIM models, IoT sensors, and project management software, to create comprehensive risk profiles. These systems can identify potential safety hazards, predict equipment maintenance needs, and forecast project delays with increasing precision. For instance, machine learning algorithms can analyze thousands of historical safety incidents to identify high-risk scenarios and recommend preventive measures.

Financial risk assessment has also been revolutionized through predictive analytics. By examining cost variations, material price fluctuations, and labor productivity data, these systems can forecast budget overruns and suggest corrective actions early in the project lifecycle. Weather pattern analysis combined with construction schedules helps optimize project timelines and reduce weather-related delays.

The implementation of predictive analytics has shown significant ROI, with leading construction firms reporting up to 25% reduction in safety incidents and 20% improvement in project delivery times. However, success requires quality data input, proper model training, and regular system calibration. As the construction industry continues to digitize, predictive analytics will become increasingly essential for proactive risk management and project success.

AI-Powered Project Optimization

AI in construction has evolved from a futuristic concept to a practical necessity, revolutionizing project optimization across the construction lifecycle. Advanced machine learning algorithms now analyze vast amounts of historical project data to predict potential delays, cost overruns, and resource allocation challenges before they materialize.

Project managers are leveraging AI-powered scheduling tools that automatically adjust timelines based on real-time progress, weather conditions, and resource availability. These systems can process thousands of schedule permutations in seconds, identifying the most efficient project delivery paths while maintaining quality standards.

Risk assessment has been transformed through predictive analytics, which examines patterns from previous projects to identify potential safety hazards and quality issues. AI algorithms continuously monitor site conditions through IoT sensors and camera feeds, alerting supervisors to safety violations or equipment maintenance needs before incidents occur.

Cost optimization has reached new heights with AI systems that analyze supplier data, material costs, and market conditions to recommend the most cost-effective procurement strategies. These platforms can forecast material requirements with unprecedented accuracy, reducing waste and improving inventory management.

Construction firms implementing AI-driven optimization report average productivity gains of 20-25% and cost reductions of 15-20%. For example, a recent high-rise project in Singapore utilized AI optimization tools to reduce construction time by three months while maintaining budget constraints through automated resource allocation and real-time progress monitoring.

Implementation Strategies for Success

Change Management Framework

Successful digital transformation in construction requires a structured change management approach to ensure smooth adoption and minimize resistance. The framework begins with a comprehensive stakeholder analysis, identifying key personnel from project managers to site workers who will be affected by new digital solutions.

Start by establishing a clear vision and communicating the benefits of digital adoption, focusing on practical advantages like improved project delivery times and reduced errors. Create a detailed implementation roadmap that breaks down the transformation into manageable phases, allowing teams to adapt gradually without disrupting ongoing projects.

Form a dedicated digital transformation team comprising both technology experts and experienced construction professionals. This team should develop targeted training programs for different user groups, addressing specific needs and skill levels. Regular feedback sessions help identify adoption challenges early and enable quick adjustments to the implementation strategy.

Document and standardize new digital processes, creating easy-to-follow guidelines that align with existing construction workflows. Monitor adoption metrics and celebrate early wins to maintain momentum and demonstrate value. Address resistance through open dialogue and practical demonstrations of how digital tools solve everyday construction challenges.

Establish a support system including technical assistance and peer mentoring to help users transition confidently. Regular assessment of the change management process ensures continuous improvement and helps identify areas requiring additional attention or resources.

Training and Skills Development

Successful digital transformation in construction requires a comprehensive approach to workforce development and skills training. Organizations must implement structured training programs that address both technical competencies and digital literacy across all organizational levels.

Key focus areas should include Building Information Modeling (BIM) proficiency, project management software utilization, and data analytics capabilities. Companies are finding success with blended learning approaches, combining traditional classroom instruction with hands-on practical applications and online learning modules.

Construction firms should prioritize creating digital champions within their teams – individuals who can lead by example and support peers in adopting new technologies. These champions often emerge from younger staff members who demonstrate natural aptitude with digital tools, though experience in construction fundamentals remains crucial.

Regular skills assessments help identify gaps and inform targeted training initiatives. Progressive organizations are implementing mentorship programs, pairing digitally proficient team members with those requiring additional support. This approach ensures knowledge transfer while maintaining productivity during the transition period.

Investment in continuous learning platforms and certification programs demonstrates commitment to employee development while ensuring the workforce remains current with evolving technology. Virtual reality simulations and augmented reality training tools are proving particularly effective for safety training and equipment operation instruction.

Critical to success is ensuring training programs align with specific organizational needs and project requirements, rather than pursuing technology adoption for its own sake. Regular feedback loops and performance metrics help measure training effectiveness and guide program adjustments.

Case Study: Digital Success Stories

The construction industry has witnessed several remarkable digital transformation success stories that demonstrate the tangible benefits of technological adoption. One notable example is the Shanghai Tower project, where Building Information Modeling (BIM) implementation resulted in a 32% reduction in material waste and shortened the construction schedule by four months. The project team utilized integrated digital platforms to coordinate between 25 different contractors, effectively managing complex geometrical challenges in real-time.

In Sweden, the Stockholm Bypass Project leveraged digital twin technology to create a virtual replica of the 21-kilometer highway tunnel. This innovative approach enabled stakeholders to simulate construction sequences, identify potential conflicts, and optimize resource allocation, resulting in a 15% cost reduction and improved safety protocols.

Balfour Beatty’s implementation of artificial intelligence and machine learning on their UK projects showcases another success story. By utilizing predictive analytics for equipment maintenance and worker safety, they achieved a 20% increase in productivity and reduced on-site accidents by 25%. Their digital transformation initiative included mobile apps for real-time progress tracking and automated reporting systems.

The Denver International Airport’s expansion project demonstrates the power of cloud-based collaboration platforms. The project team utilized integrated project delivery (IPD) methods combined with digital tools, enabling seamless coordination among 400+ team members across different locations. This digital approach resulted in a 25% faster document processing time and significant reduction in RFI response times from weeks to days.

Australian contractor Multiplex’s adoption of reality capture technology and 4D scheduling on their Collins Arch project in Melbourne showcased how digital transformation can enhance quality control. Using drones and LiDAR scanning integrated with project management software, they achieved 99.8% accuracy in construction verification and reduced rework costs by 30%.

These success stories highlight how strategic digital transformation initiatives, when properly implemented, can deliver measurable improvements in efficiency, cost savings, and project outcomes across diverse construction scenarios.

The digital transformation of the construction industry has emerged as a fundamental driver of innovation, efficiency, and competitive advantage. As we’ve explored throughout this article, the integration of digital technologies, from BIM and IoT to AI and cloud-based collaboration platforms, is revolutionizing how construction projects are planned, executed, and managed.

The successful implementation of digital transformation requires a strategic approach combining technological adoption with organizational change management. Companies that have embraced this evolution are seeing tangible benefits: improved project delivery times, reduced costs, enhanced safety measures, and better resource utilization.

Looking ahead, the construction industry is poised for even greater technological advancement. Emerging technologies like digital twins, autonomous equipment, and advanced analytics will further reshape construction practices. The integration of sustainable building practices with digital tools will become increasingly important as environmental considerations take center stage in construction planning.

However, challenges remain. Organizations must continue investing in workforce development, cybersecurity measures, and technological infrastructure. Success in this digital age requires a commitment to continuous learning and adaptation.

The future of construction is undeniably digital. Companies that prioritize digital transformation today will be better positioned to meet tomorrow’s challenges, deliver superior project outcomes, and maintain competitive advantage in an increasingly technology-driven industry. The journey of digital transformation in construction is not just about technology adoption—it’s about creating a more efficient, sustainable, and innovative future for the industry.