In today’s complex construction landscape, mastering the triple constraints of time, cost, and scope determines the difference between project success and failure. Understanding how these fundamental limitations shape cost management strategies has become increasingly critical, particularly as projects grow in complexity and scale. Recent industry data reveals that 65% of large construction projects exceed their budgets and 35% miss their deadlines, primarily due to poor constraint management.

The interplay between these three constraints creates a delicate balance that project managers must maintain throughout the project lifecycle. When one constraint shifts, it inevitably impacts the others – extending project timelines increases costs, reducing budgets can compromise quality, and expanding scope affects both schedule and resources. For construction professionals, recognizing these dependencies isn’t merely theoretical; it’s the cornerstone of effective project delivery.

This dynamic relationship becomes especially crucial in today’s volatile market, where material costs fluctuate unpredictably and skilled labor shortages persist. Success demands not just understanding these constraints individually, but mastering their collective impact on project outcomes. As we examine each constraint in detail, we’ll reveal proven strategies that leading construction firms use to navigate these challenges while maintaining project integrity and profitability.

Time Constraints: The Schedule-Cost Balance

Acceleration Costs and Schedule Compression

When project timelines need compression, costs typically increase exponentially. This acceleration phenomenon, known in the construction industry as “crashing,” requires careful analysis of the cost-benefit relationship between shorter durations and increased resource allocation.

The primary cost drivers in schedule compression include overtime labor premiums, additional shift differentials, and the need for extra equipment or materials to support concurrent activities. For instance, implementing a second shift might increase labor costs by 15-25% due to shift differentials, while overtime work often commands a 50-100% premium over standard rates.

Project managers must evaluate the critical path activities where acceleration will yield the most significant schedule benefits. Non-critical activities, when compressed, only generate additional costs without improving overall project completion times. Studies show that optimal compression typically occurs within the first 15-20% of schedule reduction, after which diminishing returns set in.

Key considerations for cost-effective schedule compression include:

– Resource availability and associated premium costs

– Impact on project quality and rework potential

– Coordination challenges with multiple trades working simultaneously

– Material procurement lead times and expediting fees

– Equipment availability and rental cost premiums

Successful schedule compression requires detailed planning and continuous monitoring of cost impacts. Industry best practices suggest maintaining a compression cost curve that tracks the relationship between duration reduction and cost increases, enabling informed decisions about acceleration strategies while maintaining project profitability.

Resource Allocation Under Time Pressure

In the fast-paced construction industry, effective resource allocation and cost control under time pressure presents significant challenges for project managers. When deadlines tighten, the natural tendency is to increase resource deployment, often leading to cost overruns and reduced efficiency.

Research indicates that up to 40% of construction projects experience resource misallocation when facing compressed schedules. This typically manifests in three critical areas: labor overtime costs, equipment utilization inefficiencies, and material procurement rush orders.

To effectively manage resources under time constraints, successful project managers implement several key strategies. First, they utilize dynamic resource leveling techniques, adjusting workforce distribution based on critical path activities. This approach ensures optimal labor utilization while minimizing overtime expenses.

Second, they employ just-in-time delivery systems for materials, carefully balanced with buffer stocks for critical components. This strategy reduces storage costs while maintaining schedule integrity. Equipment scheduling becomes more precise, with detailed allocation plans that minimize idle time and maximize productivity during peak periods.

Third, they maintain robust contingency plans for resource reallocation. When unexpected delays occur, having pre-identified alternative suppliers, backup equipment sources, and cross-trained personnel becomes invaluable. This flexibility allows for rapid response to schedule pressures without significant cost implications.

Project managers must remember that while time pressure may necessitate increased resource allocation, strategic planning and systematic deployment remain crucial for maintaining project viability and profitability.

Quality Requirements: Balancing Standards and Budget

Material Selection and Cost Trade-offs

In construction project management, material procurement decisions significantly impact both project costs and outcomes. The selection of materials requires careful consideration of quality grades, availability, and price points to maintain budget constraints while meeting project specifications.

High-grade materials often command premium prices but can reduce long-term maintenance costs and enhance project durability. For instance, selecting premium-grade steel for structural components may increase initial costs by 15-20% but can extend the structure’s lifespan by decades and reduce maintenance requirements.

Conversely, opting for standard-grade materials might lower upfront expenses but could lead to higher lifecycle costs. This trade-off becomes particularly evident in elements like insulation, where higher-quality materials can significantly impact energy efficiency and long-term operating costs.

Project managers must consider factors beyond simple unit pricing:

– Material availability and lead times

– Transportation and storage costs

– Installation complexity and labor requirements

– Warranty terms and replacement costs

– Environmental impact and sustainability requirements

– Local building codes and regulations

Successful cost management often involves strategic mixing of premium and standard materials based on their application and importance. Critical structural components may warrant higher-grade materials, while non-structural elements might accommodate standard alternatives without compromising overall quality.

A systematic approach to material selection, supported by detailed cost-benefit analysis and lifecycle cost assessments, helps optimize project budgets while maintaining quality standards.

Quality Control Measures and Their Cost Impact

Quality control measures in construction projects represent a significant investment that directly impacts project costs while safeguarding deliverable standards. Industry research indicates that comprehensive quality management systems typically account for 3-7% of total project costs, yet they can prevent costly rework that often exceeds 12% of project value when quality issues arise.

Key quality control measures include material testing, third-party inspections, and documentation systems. Material testing laboratories charge between $2,000 to $5,000 per month for regular concrete and soil analysis, while specialized testing for structural elements can cost substantially more. Third-party inspections, essential for regulatory compliance and quality assurance, typically range from $75 to $150 per hour.

Digital quality management systems, while requiring initial investments of $10,000 to $50,000 depending on project size, demonstrate significant cost benefits through improved documentation, faster issue resolution, and reduced rework. These systems enable real-time monitoring and reporting, potentially reducing quality-related delays by up to 45%.

Implementation of ISO 9001 standards in construction projects requires dedicated quality management personnel, typically commanding salaries between $75,000 to $120,000 annually. However, certified quality management systems often result in insurance premium reductions and improved bid competitiveness, offering long-term cost benefits.

The key to optimizing quality control costs lies in early implementation and integration with project planning. Studies show that every dollar invested in prevention activities saves approximately four dollars in quality-related failures and rework costs.

Scope Management: Defining Project Boundaries

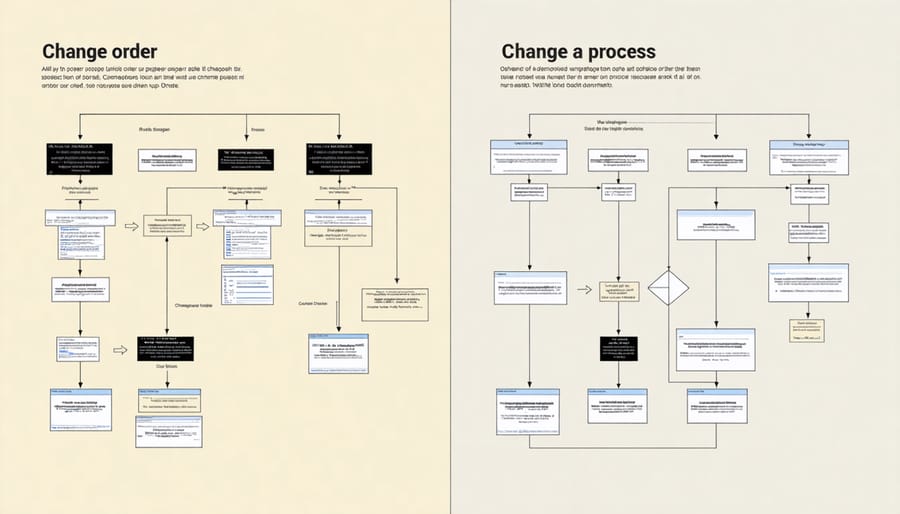

Change Order Management

Change order management represents one of the most critical aspects of cost control in construction projects. When scope changes occur, they invariably impact the project’s financial framework, creating ripple effects throughout the entire project lifecycle. Research indicates that construction projects typically experience a 5-10% cost increase due to change orders, with some complex projects seeing increases of up to 15%.

These scope modifications often arise from various sources, including client requests, unforeseen site conditions, regulatory requirements, or design modifications. Each change must be carefully evaluated not just for its direct costs, but also for its indirect impacts on other project elements. For instance, a seemingly simple modification to a building’s electrical system might necessitate structural adjustments, affecting both material costs and labor requirements.

To effectively manage these changes, project managers must implement robust change order procedures. This includes detailed documentation of the proposed changes, comprehensive cost analysis, and clear communication with all stakeholders. A well-structured change order process should include:

– Initial change request evaluation

– Detailed cost impact analysis

– Schedule impact assessment

– Risk evaluation

– Stakeholder approval workflow

– Documentation and tracking systems

Industry best practices suggest establishing a change order contingency of 3-5% of the total project budget during the planning phase. This proactive approach helps buffer against unexpected scope modifications while maintaining project financial stability. Additionally, implementing a streamlined approval process can minimize delays and reduce the administrative costs associated with change orders.

Scope Creep Prevention Strategies

To prevent cost overruns in construction projects, implementing robust effective scope management strategies is crucial. Start by establishing a detailed scope baseline during the planning phase, complete with clear deliverables, milestones, and exclusions. This foundation serves as a reference point for evaluating potential changes throughout the project lifecycle.

Implement a formal change control process that requires thorough documentation and approval for any scope modifications. This should include impact assessments on cost, schedule, and quality before accepting changes. Consider using a change control board comprising key stakeholders to evaluate and approve scope alterations.

Regular scope verification meetings with stakeholders help identify potential deviations early. These sessions should compare current work against the original scope baseline, allowing for prompt corrective actions when necessary. Document all discussions and decisions to maintain accountability.

Create a comprehensive Work Breakdown Structure (WBS) that clearly defines project components and their boundaries. This tool helps prevent scope ambiguity and provides a structured framework for monitoring progress. Utilize scope tracking metrics and progress reports to maintain visibility on potential scope creep indicators.

Train project team members to recognize and report scope creep warning signs. Establish clear communication channels for raising concerns about scope-related issues. Remember that successful scope management requires constant vigilance and proactive intervention to protect project costs and timelines.

Practical Implementation Strategies

Successful management of the three project constraints requires a systematic approach and proven methodologies. Based on extensive industry experience and case studies, here are effective strategies for managing each constraint while maintaining project equilibrium.

For time management, implement a detailed critical path analysis and utilize advanced scheduling software to identify potential bottlenecks early. Establish buffer zones in your timeline for unexpected delays and maintain regular schedule reviews with key stakeholders. Construction firms that adopt this approach report a 23% improvement in meeting project deadlines.

Quality control demands a comprehensive quality management plan with clear metrics and checkpoints. Implement a robust inspection protocol at key project milestones and utilize digital quality management tools for real-time monitoring. Document all quality-related decisions and maintain detailed records of materials testing and inspections.

Scope management requires clear documentation and a formal change control process. Develop detailed work breakdown structures (WBS) and establish a change review board to evaluate modification requests. Industry leaders recommend using BIM technology to visualize scope changes and their impacts before implementation.

To balance these constraints effectively:

– Hold weekly constraint analysis meetings with project teams

– Utilize earned value management (EVM) techniques to track progress

– Implement a digital dashboard for real-time monitoring of all three constraints

– Establish clear communication channels for stakeholder updates

– Develop contingency plans for various constraint scenarios

Remember that successful constraint management often requires trade-offs. Document these decisions thoroughly and communicate them clearly to all stakeholders. Regular monitoring and adjustment of these strategies ensure optimal project outcomes while maintaining the delicate balance between time, quality, and scope.

Understanding and effectively managing the triple constraints of time, cost, and quality is crucial for successful project delivery in the construction industry. As we’ve explored throughout this article, these constraints are deeply interconnected, and changes in one invariably affect the others. Construction professionals must develop a balanced approach that considers all three elements while maintaining project scope integrity.

To effectively manage these constraints, consider implementing the following strategies:

1. Establish clear baseline measurements and KPIs for each constraint at project inception

2. Develop robust monitoring systems to track variations in real-time

3. Create contingency plans for common constraint conflicts

4. Maintain open communication channels with all stakeholders

5. Regularly review and adjust constraint management strategies

Remember that successful project management isn’t about achieving perfection in all three areas, but rather finding the optimal balance that meets project objectives and stakeholder expectations. By understanding these constraints’ dynamic nature and implementing appropriate control measures, construction professionals can better navigate project challenges and deliver successful outcomes.

Moving forward, focus on developing integrated management systems that address all three constraints simultaneously while maintaining flexibility to adapt to changing project conditions. This approach will help ensure project success while maintaining profitability and client satisfaction.