In today’s energy-conscious building landscape, HVAC energy management systems represent the cornerstone of operational efficiency and cost control. These sophisticated platforms, integrated with smart building technology, deliver unprecedented control over heating, cooling, and ventilation systems while reducing energy consumption by up to 30%. Modern EMS solutions combine real-time monitoring, predictive analytics, and automated response mechanisms to optimize HVAC performance across entire facilities. For building owners and facility managers, implementing these systems has become not just an environmental imperative but a critical business decision that directly impacts operational costs and tenant satisfaction. As energy prices continue to rise and environmental regulations tighten, understanding and leveraging advanced HVAC energy management capabilities has become essential for maintaining competitive advantage in commercial real estate and industrial facilities management.

Core Components of Modern HVAC Energy Management Systems

Smart Sensors and IoT Integration

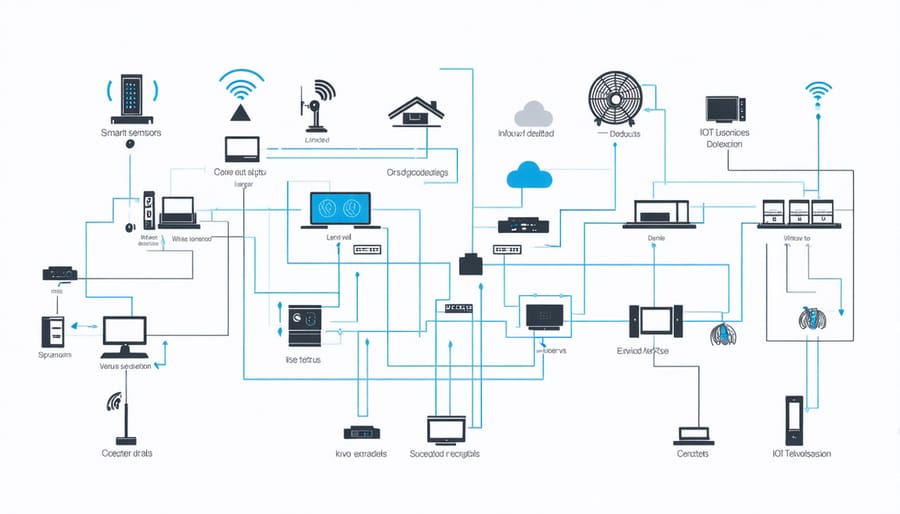

Modern HVAC systems have evolved significantly with the integration of smart sensors and IoT technology, revolutionizing how buildings manage their energy consumption. IoT integration in building management has enabled real-time monitoring and precise control of HVAC operations through a network of sophisticated sensors.

These sensor networks typically include temperature sensors, humidity monitors, occupancy detectors, and CO2 sensors strategically placed throughout the facility. Each sensor communicates wirelessly with the central building management system (BMS), providing continuous data streams that enable dynamic system adjustments. Advanced pressure sensors monitor airflow and filter conditions, while smart thermostats learn occupancy patterns and optimize temperature settings automatically.

The IoT infrastructure allows for seamless data collection and analysis, enabling predictive maintenance and performance optimization. Machine learning algorithms process this data to identify patterns, predict equipment failures, and automatically adjust system parameters for maximum efficiency. For instance, occupancy sensors can trigger automatic adjustments to ventilation rates based on real-time building usage, while smart algorithms can optimize start-up times based on weather forecasts and historical performance data.

These systems also facilitate remote monitoring and control through secure cloud platforms, allowing facility managers to access system data and make adjustments from anywhere. Integration capabilities extend to other building systems, creating a comprehensive energy management ecosystem that can significantly reduce energy consumption while maintaining optimal comfort levels.

Advanced Control Algorithms

Modern HVAC energy management systems increasingly leverage artificial intelligence and machine learning algorithms to optimize building performance. These advanced control algorithms analyze vast amounts of operational data, including occupancy patterns, weather conditions, thermal loads, and equipment performance metrics, to make real-time adjustments that maximize efficiency.

Predictive analytics capabilities enable systems to anticipate heating and cooling needs based on historical patterns and external factors. For example, the system might begin pre-cooling spaces before peak occupancy periods or adjust ventilation rates based on CO2 levels and predicted occupancy. Machine learning algorithms continuously refine these predictions, improving accuracy over time.

Deep learning networks can identify complex relationships between various building parameters, leading to more sophisticated control strategies. These systems can detect equipment inefficiencies, predict maintenance needs, and automatically adjust operating parameters to optimize energy consumption while maintaining comfort levels.

Model predictive control (MPC) algorithms are particularly effective in managing complex HVAC systems. By simulating multiple possible control scenarios and selecting the most efficient option, MPC can reduce energy consumption by 15-25% compared to conventional control methods. These algorithms account for factors such as energy prices, weather forecasts, and building thermal dynamics to create optimal operating schedules.

Recent developments in reinforcement learning have enabled HVAC systems to adapt to changing conditions autonomously, learning from their actions to improve performance continuously. This self-optimization capability ensures that energy efficiency strategies remain effective even as building usage patterns and environmental conditions change over time.

Real-Time Monitoring and Analytics

Performance Metrics and Benchmarking

Effective HVAC energy management relies heavily on monitoring and analyzing key performance indicators (KPIs). Industry-standard metrics include Energy Use Intensity (EUI), measured in kWh/m²/year, and Coefficient of Performance (COP) for heating and cooling systems. Building managers implementing modern HVAC optimization technologies should target a minimum COP of 3.0 for heat pumps and chillers.

ASHRAE Standard 90.1 provides benchmark values for system efficiency, while ISO 50001 certification requirements offer comprehensive energy performance frameworks. Critical metrics include:

• System Runtime Efficiency (SRE)

• Energy Cost Index (ECI)

• Temperature Differential (ΔT)

• Return on Investment (ROI)

• Carbon Dioxide Equivalent (CO2e) emissions

Leading facilities typically achieve 15-30% energy savings through proper benchmarking and continuous monitoring. Real-time performance tracking enables immediate response to efficiency drops, while historical data analysis helps identify seasonal patterns and optimization opportunities. Advanced building automation systems (BAS) should maintain a Power Usage Effectiveness (PUE) ratio below 1.5 for optimal energy efficiency.

Predictive Maintenance Capabilities

Modern HVAC energy management systems incorporate sophisticated predictive maintenance capabilities that leverage real-time data analytics and machine learning algorithms to anticipate potential equipment failures before they occur. These systems continuously monitor key performance indicators such as temperature differentials, pressure readings, energy consumption patterns, and equipment vibration levels.

By analyzing historical performance data alongside current operating conditions, predictive maintenance algorithms can identify subtle changes in equipment behavior that may indicate developing issues. This proactive approach allows facility managers to schedule maintenance activities strategically, reducing unexpected downtime and extending equipment lifespan.

The system generates maintenance alerts based on actual equipment condition rather than fixed time intervals, optimizing maintenance schedules and resource allocation. For example, when a compressor shows early signs of degraded performance, the system can alert maintenance staff before the issue impacts overall system efficiency or leads to failure.

Advanced diagnostic capabilities can also differentiate between minor adjustments and critical repairs, helping prioritize maintenance activities. This data-driven approach typically reduces maintenance costs by 15-30% while improving system reliability. The integration of IoT sensors and cloud-based analytics platforms further enhances these predictive capabilities, providing facility managers with comprehensive insights for informed decision-making.

Integration with Building Management Systems

Cross-System Communication

Effective cross-system communication is crucial for modern HVAC energy management systems, relying on standardized protocols that enable seamless integration between different building components. BACnet remains the industry-leading protocol, facilitating interoperability between HVAC equipment, lighting systems, and security components from various manufacturers.

Modbus and LonWorks protocols also play significant roles in building automation, offering robust communication frameworks for different system architectures. These protocols ensure that data flows smoothly between sensors, controllers, and management interfaces, enabling real-time monitoring and automated responses to changing conditions.

The emergence of IoT-enabled devices has introduced new integration standards, with REST APIs and MQTT protocols becoming increasingly prevalent. These modern protocols enable cloud-based monitoring and control, allowing facility managers to access system data and make adjustments remotely.

System integrators must carefully consider protocol compatibility when designing or upgrading building management systems. Many contemporary solutions incorporate gateway devices that translate between different protocols, ensuring older equipment can communicate with newer systems. This approach protects existing investments while enabling gradual system modernization.

Security considerations are paramount in cross-system communication. Implementation of encrypted communications, secure authentication methods, and regular security updates helps protect against unauthorized access and cyber threats, ensuring the integrity of building operations and occupant safety.

User Interface and Control Options

Modern HVAC energy management systems offer sophisticated user interfaces that combine intuitive operation with comprehensive control capabilities. Facility managers can access their building’s HVAC systems through various platforms, including desktop applications, web-based dashboards, and mobile apps, enabling remote monitoring and control from anywhere.

These interfaces typically feature real-time visualization of system performance through graphical displays, showing temperature zones, occupancy patterns, and energy consumption metrics. Interactive floor plans allow operators to quickly identify and respond to issues across different building areas, while customizable widgets provide at-a-glance status updates of critical parameters.

Advanced control options include scheduling capabilities for different zones and time periods, automated setpoint adjustments based on occupancy sensors, and demand-response programming. Many systems now incorporate artificial intelligence and machine learning algorithms that optimize operations automatically, learning from historical data and user preferences to enhance efficiency.

Security features are integrated into these interfaces, with role-based access control ensuring that different users have appropriate permission levels. Multi-factor authentication and encrypted communications protect system integrity while maintaining ease of use.

Mobile functionality has become increasingly important, with apps providing push notifications for system alerts and the ability to make immediate adjustments from smartphones or tablets. These mobile interfaces maintain the same level of control as desktop versions while offering the convenience of on-the-go management.

ROI and Implementation Considerations

Cost-Benefit Analysis

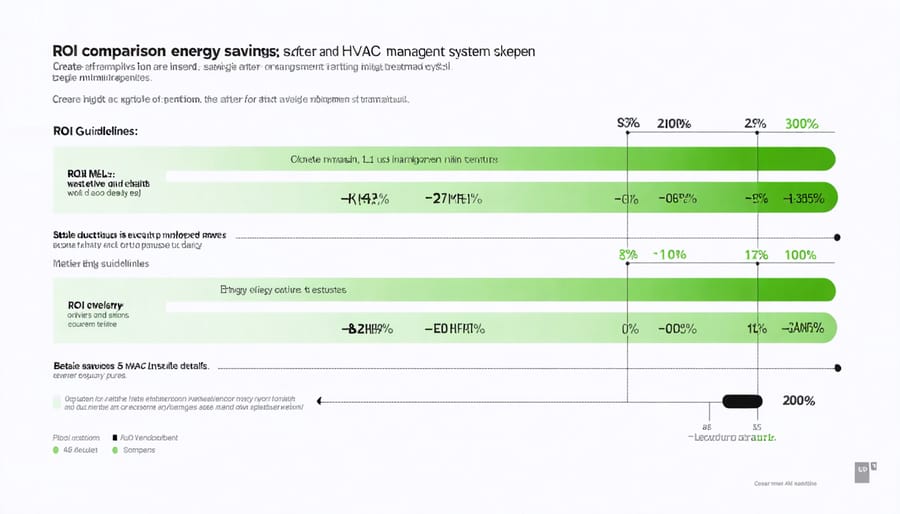

The implementation of HVAC energy management systems presents a compelling financial case when analyzing both initial investments and long-term returns. According to industry data, modern EMS installations typically require an initial investment ranging from $2.00 to $4.00 per square foot, depending on building size and system complexity. However, these systems consistently deliver significant returns through various energy cost reduction strategies.

Case studies from commercial buildings demonstrate average energy savings of 20-30% within the first year of implementation. For a 50,000-square-foot commercial building with annual energy costs of $100,000, this translates to potential savings of $20,000-$30,000 annually. The payback period typically ranges from 2-4 years, with ROI calculations showing internal rates of return exceeding 25% over a 10-year period.

Additional financial benefits include reduced maintenance costs (15-20% decrease), extended equipment life (20-25% increase), and lower emergency repair expenses (30-40% reduction). These systems also contribute to increased property values, with studies indicating a 3-7% premium for buildings featuring advanced energy management capabilities.

Labor cost savings are equally significant, with automated systems reducing manual intervention by up to 40%. Real-time monitoring and predictive maintenance capabilities help prevent costly system failures, while detailed energy consumption data enables more effective budget planning and resource allocation. When factoring in utility incentives and tax benefits available in many jurisdictions, the total cost of ownership becomes even more attractive for facility managers and building owners.

Implementation Best Practices

Successful implementation of HVAC energy management systems requires a strategic, multi-phase approach focused on optimization and long-term sustainability. Begin with a comprehensive energy audit to establish baseline performance metrics and identify key improvement opportunities. This initial assessment should include detailed monitoring of current energy consumption patterns and system efficiency levels.

Deploy advanced sensors and monitoring equipment at critical points throughout the HVAC infrastructure to enable real-time data collection and analysis. Ensure proper calibration and placement of these devices to gather accurate, actionable data. Implement a staged rollout strategy, starting with pilot areas to validate system performance before full-scale deployment.

Integration with existing building management systems (BMS) is crucial for seamless operation. Establish clear communication protocols between different system components and verify compatibility with current infrastructure. Configure automated control algorithms based on occupancy patterns, weather conditions, and operational schedules.

Staff training is essential for maximizing system benefits. Develop comprehensive training programs for facility managers and maintenance personnel, covering both routine operations and troubleshooting procedures. Establish clear performance metrics and monitoring protocols to track system effectiveness.

Regular system optimization should include continuous commissioning practices, periodic performance reviews, and updates to control strategies based on collected data. Implement predictive maintenance protocols to prevent system failures and maintain optimal efficiency. Document all procedures and maintain detailed records of system modifications and performance improvements for future reference and analysis.

Energy management systems for HVAC have proven to be transformative solutions in modern building operations, delivering substantial benefits across multiple fronts. The implementation of these systems consistently demonstrates ROI through reduced energy consumption, with many facilities reporting 20-30% savings in HVAC-related energy costs. Beyond financial advantages, these systems have become instrumental in achieving sustainability goals and maintaining occupant comfort.

Looking ahead, the future of HVAC energy management systems appears increasingly promising. The integration of artificial intelligence and machine learning capabilities is enabling more sophisticated predictive maintenance and optimization strategies. IoT sensors and advanced analytics are becoming more affordable and accessible, making these systems viable for a broader range of buildings and facilities.

Industry trends suggest that upcoming developments will focus on enhanced integration with renewable energy sources, improved grid responsiveness, and more sophisticated demand response capabilities. The rise of cloud-based solutions and mobile accessibility is making system management more convenient and effective than ever before.

For facility managers and building owners, the decision to implement these systems is becoming less about whether to invest and more about how to maximize their potential. As regulatory requirements for energy efficiency continue to tighten and sustainability becomes increasingly crucial, HVAC energy management systems will remain at the forefront of building technology innovation, offering an essential tool for modern facility management and environmental stewardship.