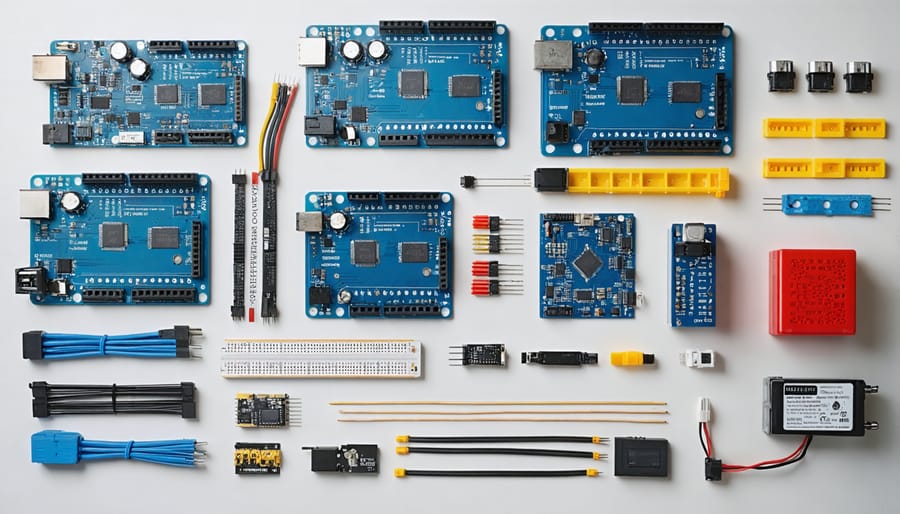

Transform your construction site into a smart, efficient workspace through strategic electronic DIY projects that leverage modern construction technology innovations. Installing wireless sensor networks monitors structural integrity and environmental conditions in real-time, while custom-built LED lighting systems reduce energy consumption by up to 75%. Deploy Arduino-based safety monitoring systems to track worker movements and equipment usage patterns, enabling data-driven decision-making for site optimization.

These DIY electronic solutions deliver immediate ROI through reduced operational costs and enhanced safety protocols. Professional-grade components, when properly integrated, create robust systems that withstand harsh construction environments while providing reliable performance. Advanced microcontrollers and sensors, combined with proper weatherproofing techniques, ensure long-term durability and minimal maintenance requirements.

Focus on scalable solutions that grow with your project needs – from basic environmental monitoring to comprehensive site automation. Integration with existing building management systems maximizes efficiency while maintaining compliance with industry safety standards. Select components rated for industrial use and implement redundant power systems to ensure continuous operation in demanding construction environments.

Site Monitoring and Security Systems

Wireless Camera Networks

Setting up a wireless camera network offers robust security monitoring capabilities while maintaining cost-effectiveness. The fundamental components include IP cameras, a network video recorder (NVR), motion sensors, and a dedicated wireless router. Begin by strategically positioning cameras to maximize coverage of critical areas, ensuring each device has reliable power access.

For optimal performance, utilize Power over Ethernet (PoE) cameras when possible, as they reduce wiring complexity and provide stable power delivery. Configure your NVR to establish communication with each camera, implementing appropriate security protocols such as WPA3 encryption and unique passwords for each device.

Motion sensors can be integrated through microcontroller boards like Arduino or Raspberry Pi, creating a comprehensive detection system. Program these sensors to trigger camera recording and send instant notifications to your monitoring device. Consider implementing zone-based detection to minimize false alarms in high-traffic areas.

Storage management is crucial for continuous operation. Configure recording parameters based on motion detection rather than continuous recording to optimize storage capacity. Implement a redundant backup system using network-attached storage (NAS) devices to preserve critical footage.

For remote access, establish a secure VPN connection to your network, enabling authorized personnel to monitor feeds from any location. Regular maintenance should include firmware updates, network security audits, and physical inspection of camera positions and connections to ensure consistent system reliability.

Access Control Systems

Access control systems represent a compelling DIY electronic project that combines security functionality with personnel management capabilities. By implementing RFID-based entry systems, construction professionals can create customized solutions that monitor and control site access while maintaining detailed logs of personnel movement.

The core components typically include an Arduino or similar microcontroller, RFID reader module (such as the RC522), electronic door locks, and RFID cards or key fobs. The system can be enhanced with additional features like LCD displays for user feedback, real-time clock modules for accurate timestamping, and SD card storage for maintaining comprehensive access logs.

Implementation begins with proper wiring of the RFID reader to the microcontroller, followed by programming the authentication logic. Modern systems can be integrated with Wi-Fi modules to enable remote monitoring and real-time notifications. This allows project managers to receive instant alerts about unauthorized access attempts or track worker attendance patterns.

For enhanced security, the system can be programmed with multiple access levels, enabling different permissions for various personnel categories. Integration with existing security infrastructure is possible through relay modules, making it adaptable to different site requirements.

Key considerations include weather-proofing for outdoor installations, backup power systems for continuous operation, and regular maintenance of the database storing authorized RFID credentials. With proper implementation, these systems provide a cost-effective solution for site security and personnel tracking.

Environmental Monitoring Solutions

Temperature and Humidity Sensors

Temperature and humidity monitoring systems represent critical components in modern construction environments, offering essential data for maintaining optimal working conditions and ensuring material integrity. By implementing DIY sensor networks, construction professionals can create cost-effective solutions for environmental monitoring across their sites.

The foundation of these systems typically comprises DHT22 or BME280 sensors, which offer industrial-grade accuracy for both temperature and relative humidity measurements. When coupled with microcontrollers like Arduino or ESP32, these sensors can form comprehensive monitoring networks that provide real-time data access.

Implementation begins with proper sensor placement, typically positioning units at strategic locations such as concrete curing areas, material storage facilities, and workspace environments. The sensors connect to the microcontroller through digital pins, with power requirements easily met through standard 3.3V or 5V outputs.

Data logging capabilities can be enhanced by incorporating SD card modules or wireless connectivity options. ESP32-based systems can transmit readings directly to cloud platforms, enabling remote monitoring and automated alert systems when conditions exceed predetermined thresholds.

For enhanced functionality, consider integrating automated response systems. These might include activating ventilation fans when humidity levels rise too high or triggering heating elements during cold periods. Such automation not only maintains optimal conditions but also reduces energy consumption and manual intervention requirements.

Calibration and maintenance remain crucial for long-term reliability. Regular comparison with certified measurement devices ensures accuracy, while protective housings shield sensors from construction dust and debris. This approach to environmental monitoring combines cost-effectiveness with professional-grade functionality, making it an invaluable addition to any construction site’s management system.

Dust and Air Quality Monitors

Creating IoT-enabled air quality monitors represents a significant advancement in construction site safety and environmental monitoring. These DIY devices combine affordable sensors with microcontrollers to provide real-time data on particulate matter, volatile organic compounds (VOCs), and other airborne contaminants.

The core components typically include a particulate matter sensor (such as the PMSx003 or SDS011), a temperature/humidity sensor (DHT22 or BME280), and a microcontroller like the ESP32 or Arduino Nano 33 IoT. These elements work together to deliver comprehensive air quality measurements while maintaining industrial-grade accuracy.

Implementation begins with sensor calibration and proper housing design to protect electronic components from construction site conditions. The housing should include appropriate inlet and outlet ports for air sampling while preventing moisture and debris infiltration. Industry professionals recommend using IP65-rated enclosures and installing HEPA-grade filters at intake points.

Data collection and transmission capabilities can be enhanced through:

– WiFi connectivity for real-time monitoring

– Local SD card storage for backup

– Integration with existing building management systems

– Mobile app notifications for threshold violations

To ensure reliability, these monitors should be positioned strategically around construction sites, particularly near demolition areas, concrete cutting stations, and material storage zones. Regular maintenance includes sensor cleaning, calibration checks, and firmware updates.

The collected data proves invaluable for:

– OSHA compliance documentation

– Environmental impact assessments

– Worker safety optimization

– Indoor air quality verification during finishing stages

Cost-effective and customizable, these DIY monitors enable construction professionals to maintain stringent air quality standards while providing documented evidence of environmental responsibility.

Power Management and Energy Monitoring

Smart Power Distribution Units

Smart power distribution units (PDUs) represent a significant advancement in energy efficiency in construction and site management. These DIY projects involve creating intelligent power strips that monitor and control electricity usage across multiple outlets, providing real-time data on power consumption and load distribution.

The core components typically include a microcontroller (such as Arduino or Raspberry Pi), current sensors for each outlet, voltage monitoring circuits, and relay modules for remote switching capabilities. Implementation requires careful consideration of safety protocols, particularly when working with mains voltage, and should always comply with local electrical codes.

Key features of these smart PDUs include:

– Real-time power consumption monitoring

– Remote outlet control via mobile applications

– Overcurrent protection mechanisms

– Data logging capabilities for usage analysis

– Programmable scheduling for automated power management

Construction professionals can enhance their power management systems by incorporating network connectivity, enabling integration with building management systems (BMS). This allows for comprehensive power usage analytics and predictive maintenance scheduling.

When designing these units, emphasis should be placed on robust surge protection, proper grounding, and heat dissipation. The final assembly should be housed in an appropriate enclosure rated for the intended environment, with clear labeling for safety and operational purposes.

Solar-Powered Site Lighting

Solar-powered site lighting represents a sustainable and cost-effective solution for construction site illumination. By integrating DIY solar power systems with automated lighting controls, project managers can significantly reduce energy costs while maintaining essential safety standards.

The core components of a solar-powered lighting system include photovoltaic panels, charge controllers, deep-cycle batteries, LED fixtures, and motion sensors. When designing the system, calculate the total power requirements based on operational hours and lighting coverage area. A typical setup requires 100-200W solar panels per light fixture, depending on geographical location and usage patterns.

Implementation begins with strategic placement of solar panels to maximize sun exposure, followed by proper mounting of weather-resistant LED fixtures at key locations. Install motion sensors at appropriate heights and angles to ensure optimal coverage while preventing false triggers. The system’s control unit should incorporate programmable timers and light sensors for automated operation.

For maximum efficiency, configure the system to operate at reduced brightness during low-activity periods and full intensity when motion is detected. This adaptive approach extends battery life while maintaining security requirements. Regular maintenance includes cleaning solar panels, checking electrical connections, and monitoring battery performance to ensure reliable operation throughout the project duration.

Safety and Emergency Systems

Wearable Alert Systems

Wearable alert systems represent a critical advancement in construction site safety, combining DIY electronics with personal protective equipment. These systems typically integrate accelerometers, GPS modules, and wireless communication components to create comprehensive worker protection solutions. Construction professionals can build customized devices that monitor vital signs, detect falls, and track worker location in real-time.

A basic wearable alert system consists of an Arduino Nano or ESP32 microcontroller, paired with a MPU6050 motion sensor and a GSM module for cellular connectivity. The device can be programmed to recognize dangerous situations, such as sudden impacts or prolonged periods of inactivity, automatically triggering alerts to site supervisors.

Advanced implementations might include environmental sensors to monitor temperature, humidity, and harmful gas levels. These readings can be transmitted to a central monitoring station, providing invaluable data for site safety management. The entire system can be housed in a weatherproof enclosure and mounted on a worker’s hard hat or safety vest, ensuring durability and minimal interference with daily tasks.

For optimal reliability, these systems should incorporate redundant power supplies and fail-safe mechanisms, guaranteeing continuous operation throughout extended work shifts.

Emergency Communication Networks

Emergency communication networks are critical for construction site safety and operational efficiency. A reliable DIY emergency communication system typically consists of a central control unit, multiple distributed nodes, and redundant power supplies. The foundation of such systems often incorporates low-cost microcontrollers like Arduino or Raspberry Pi, coupled with robust RF transceivers operating on industrial frequencies.

Key components include weather-resistant enclosures, high-gain antennas, and backup power systems utilizing deep-cycle batteries with solar charging capabilities. Implementation requires strategic placement of repeater nodes to ensure comprehensive site coverage, particularly in areas with challenging terrain or signal-blocking structures.

For enhanced reliability, modern systems often integrate multiple communication protocols, including LoRa for long-range transmission and mesh networking capabilities for redundancy. Essential features should include automated system health monitoring, emergency broadcast capabilities, and integration with existing site safety systems.

Construction professionals can achieve significant cost savings by building these systems in-house while maintaining compliance with relevant safety standards and frequency regulations. Regular testing and maintenance protocols ensure system readiness during critical situations.

The integration of DIY electronic projects into construction site operations has revolutionized how teams approach safety, efficiency, and project management. Through the implementation of custom-built monitoring systems, sensor networks, and automated control mechanisms, construction professionals have demonstrated that innovative electronic solutions can significantly reduce costs while enhancing operational capabilities.

The impact of these DIY initiatives extends beyond immediate cost savings. Construction sites utilizing custom electronic solutions report improved worker safety compliance, more accurate environmental monitoring, and enhanced real-time decision-making capabilities. Project managers have particularly noted the value of personalized alert systems and data collection platforms in streamlining daily operations and preventing potential hazards.

Looking ahead, the future of DIY electronic projects in construction appears increasingly promising. Emerging technologies such as artificial intelligence and Internet of Things (IoT) components are becoming more accessible, opening new possibilities for custom solutions. Construction professionals can expect to see more sophisticated DIY applications in areas such as predictive maintenance, autonomous equipment monitoring, and advanced security systems.

The success of these implementations demonstrates that with proper planning, technical knowledge, and careful execution, DIY electronic projects can become valuable assets in modern construction operations. As technology continues to evolve, the potential for innovative, cost-effective electronic solutions will only grow, making them an essential consideration for forward-thinking construction professionals.