Environmental sustainability projects are rapidly transforming the construction landscape, driving both ecological responsibility and financial performance across the industry. Through sustainable project development, construction firms are achieving remarkable results: reducing operational costs by 25-35%, increasing property values by up to 15%, and securing competitive advantages in an increasingly environmentally conscious market.

Recent data from the World Green Building Council demonstrates that green building projects deliver an average ROI of 14% within the first three years, while simultaneously reducing carbon emissions by up to 40%. For construction professionals, this represents an unprecedented opportunity to align environmental stewardship with business growth.

Leading firms are revolutionizing their approach through integrated design processes, advanced building information modeling (BIM), and innovative material selection strategies. These methodologies not only enhance project sustainability but also streamline construction timelines and improve quality control measures.

As regulatory requirements tighten and client demands evolve, mastering sustainable construction practices has become essential for long-term success in the building sector. This comprehensive guide examines proven strategies, emerging technologies, and real-world case studies that demonstrate how environmental sustainability projects deliver measurable results while positioning organizations for future growth.

Smart Energy Management Systems in Construction Projects

Real-time Energy Monitoring Technologies

Modern real-time energy monitoring technologies have revolutionized how construction projects track and optimize their environmental impact. These sophisticated systems combine IoT sensors, cloud-based analytics, and intelligent dashboards to provide unprecedented visibility into energy consumption patterns and resource utilization across construction sites.

Advanced monitoring platforms integrate seamlessly with existing cost management solutions, enabling project managers to correlate energy usage with specific activities and identify opportunities for optimization. Key features include real-time power consumption tracking, automated alert systems for unusual usage patterns, and predictive analytics for maintenance scheduling.

Industry leaders have reported energy savings of 15-30% after implementing these monitoring systems. For example, Turner Construction’s implementation of smart energy monitoring across their commercial projects resulted in a 22% reduction in energy waste during construction phases. The system’s ability to detect equipment inefficiencies and optimize operational schedules proved particularly valuable during peak usage periods.

These platforms typically incorporate:

– Wireless sensor networks for continuous data collection

– Cloud-based analytics for pattern recognition

– Mobile applications for remote monitoring

– Integration capabilities with building management systems

– Automated reporting and compliance documentation

Recent innovations include AI-powered predictive algorithms that can forecast energy demands based on construction schedules and weather patterns. This predictive capability allows project managers to optimize resource allocation and reduce peak demand charges, leading to significant cost savings while maintaining environmental commitments.

The return on investment for these systems typically materializes within 12-18 months through reduced energy costs, improved operational efficiency, and enhanced regulatory compliance reporting capabilities.

Integration with Building Management Systems

Integration with Building Management Systems (BMS) represents a crucial component in modern environmental sustainability projects, enabling real-time monitoring and optimization of building performance. By connecting various building systems through a centralized platform, organizations can achieve significant improvements in energy efficiency and operational effectiveness.

The primary advantage of BMS integration lies in its ability to coordinate multiple building systems simultaneously. HVAC, lighting, security, and other building functions can be monitored and adjusted automatically based on occupancy patterns, environmental conditions, and energy consumption data. This intelligent automation helps reduce energy waste while maintaining optimal comfort levels for occupants.

Advanced BMS platforms now incorporate machine learning algorithms that can predict maintenance needs and identify potential energy-saving opportunities. For instance, the system can analyze historical usage patterns to optimize HVAC scheduling or automatically adjust lighting levels based on natural daylight availability.

Recent case studies demonstrate the tangible benefits of BMS integration. A commercial office building in Singapore achieved a 23% reduction in energy consumption after implementing an integrated BMS solution that coordinated its chiller plant, air handling units, and lighting systems. Similarly, a hospital in Stockholm reported a 30% decrease in operational costs through smart building management integration.

Key considerations for successful BMS integration include:

– Ensuring compatibility with existing building infrastructure

– Implementing robust cybersecurity measures

– Training facility managers in system operation

– Establishing clear performance metrics

– Regular system updates and maintenance

For maximum effectiveness, BMS integration should be considered early in the project planning phase, allowing for proper infrastructure design and seamless implementation. This approach enables better system coordination and helps achieve optimal environmental performance while minimizing operational disruptions.

Waste Reduction and Circular Economy Initiatives

Material Recovery and Recycling Programs

Effective material recovery and recycling programs are critical components of sustainable construction practices, requiring a robust procurement management framework to maximize resource efficiency. Industry leaders have demonstrated that implementing comprehensive recycling systems can reduce waste disposal costs by 40-60% while meeting environmental compliance requirements.

Construction waste sorting protocols typically focus on four primary material streams: concrete and masonry, metals, wood products, and mixed recyclables. Leading contractors are now utilizing automated sorting technologies and RFID tracking systems to optimize material separation and enhance recovery rates. These systems have shown recovery rates exceeding 85% on major commercial projects.

Recent case studies from the Associated General Contractors of America reveal that successful recycling programs incorporate three essential elements: dedicated material staging areas, trained waste management personnel, and real-time tracking systems. For example, the Hudson Yards development in New York achieved a 95% recycling rate by implementing these components alongside specialized contractor training programs.

The financial benefits of material recovery extend beyond waste reduction. Recycled materials often command significant market value, particularly metals and clean concrete aggregate. Companies implementing comprehensive recycling programs report average cost savings of $250,000 annually on large-scale projects, with additional benefits from LEED certification credits and regulatory compliance.

Key considerations for program implementation include:

– Site-specific waste audit and characterization

– Material separation protocols and handling procedures

– Storage and transportation logistics

– Processing facility partnerships

– Quality control measures

– Documentation and reporting systems

To ensure program success, contractors should establish clear performance metrics, conduct regular audits, and maintain detailed documentation of diverted materials. This data-driven approach enables continuous improvement and helps demonstrate ROI to project stakeholders while supporting environmental sustainability goals.

Supply Chain Optimization

Effective supply chain optimization stands as a cornerstone of sustainable construction practices, offering significant opportunities for waste reduction and environmental impact minimization. By implementing smart procurement strategies, construction companies can dramatically reduce their carbon footprint while improving operational efficiency.

Material flow optimization represents a primary focus area, utilizing just-in-time delivery systems to minimize on-site storage requirements and reduce material waste. Advanced inventory management systems, coupled with real-time tracking technology, enable precise ordering and delivery scheduling, preventing over-procurement and subsequent material spoilage.

Digital supply chain solutions have revolutionized how construction firms manage their resource networks. Building Information Modeling (BIM) integration with supply chain management systems allows for accurate material quantity takeoffs and improved coordination between suppliers, contractors, and site teams. This digital transformation has resulted in reported waste reductions of up to 25% on major construction projects.

Supplier partnerships play a crucial role in sustainable supply chain optimization. Leading construction firms are establishing collaborative relationships with vendors who demonstrate commitment to sustainable practices. This includes selecting suppliers who use recycled materials, implement eco-friendly packaging solutions, and maintain transparent environmental policies.

Local sourcing initiatives have gained prominence, with construction companies prioritizing materials from nearby suppliers to reduce transportation emissions. Studies indicate that local sourcing can decrease supply chain-related carbon emissions by up to 40% while supporting regional economies.

Reverse logistics systems have become increasingly important, facilitating the efficient collection and recycling of construction waste. These systems ensure that unused materials and demolition waste are properly sorted, recycled, and reintegrated into the supply chain where possible, creating a more circular economy in construction.

By implementing these optimization strategies, construction firms can achieve significant environmental benefits while maintaining cost-effectiveness and project efficiency. Regular monitoring and adjustment of supply chain processes ensure continuous improvement in sustainability performance.

Water Conservation Projects

Innovative Water Management Technologies

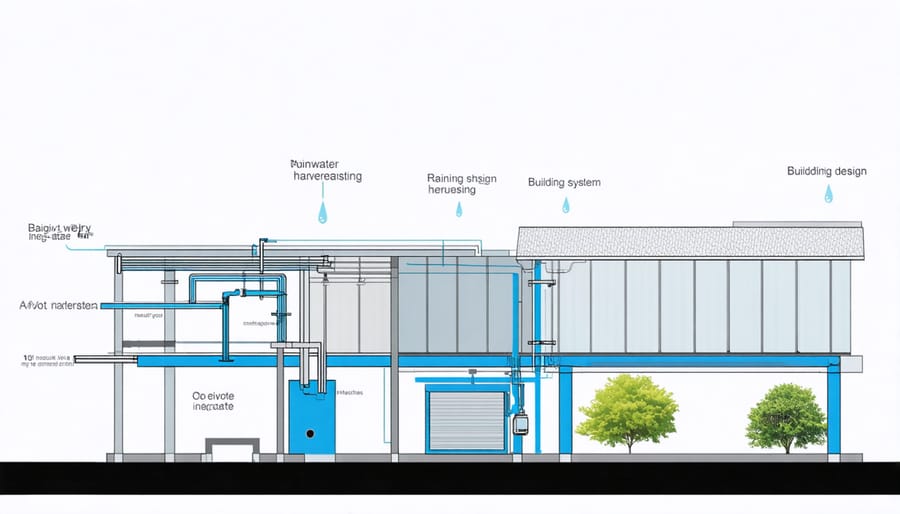

Recent advancements in water management technologies have revolutionized how construction projects approach water conservation and efficiency. Smart water metering systems, equipped with IoT sensors and real-time monitoring capabilities, now enable precise tracking of water consumption patterns and immediate leak detection. These systems typically reduce water waste by 15-30% in commercial buildings.

Advanced rainwater harvesting systems, incorporating sophisticated filtration and UV treatment processes, are increasingly being integrated into building designs. These systems can provide up to 40% of a building’s non-potable water needs, significantly reducing reliance on municipal water supplies.

Greywater recycling technologies have also evolved substantially, with new membrane bioreactor (MBR) systems offering superior water treatment efficiency. These systems can process and recycle up to 95% of greywater from sinks, showers, and laundry facilities for irrigation and toilet flushing purposes.

Smart irrigation systems utilizing weather data, soil moisture sensors, and AI-driven controllers are transforming landscape management. These systems adjust watering schedules automatically based on real-time conditions, reducing water consumption by up to 50% compared to traditional irrigation methods.

Emerging technologies like atmospheric water generators and condensate recovery systems are gaining traction in regions with water scarcity. These innovative solutions can produce 100-1000 liters of potable water daily from air humidity, depending on the system scale and atmospheric conditions, offering a sustainable alternative water source for buildings.

Greywater Systems Implementation

The implementation of greywater systems has proven successful across various commercial and residential developments, demonstrating significant water conservation and cost savings. The Aurora Water-Smart Village in Colorado serves as a prime example, where a comprehensive greywater recycling system reduced potable water consumption by 32% across 300 residential units. The project’s success hinged on careful filtration system design and strategic placement of collection points near shower and laundry facilities.

In the commercial sector, the Bullitt Center in Seattle showcases an innovative approach to greywater management. The six-story commercial building utilizes a constructed wetland system that processes 500 gallons of greywater daily, achieving zero water waste while supporting surrounding landscaping needs. The system’s sophisticated biofilters and UV treatment ensure water quality meets stringent regulatory requirements.

The Grand Hyatt Hotel in Singapore demonstrates large-scale greywater implementation success, recycling approximately 240,000 gallons annually. Their system incorporates advanced membrane filtration technology and smart monitoring systems, resulting in a 25% reduction in water utility costs since installation in 2019. The hotel’s maintenance team reports minimal operational issues, attributing this to proper initial system sizing and regular preventive maintenance protocols.

These case studies highlight key success factors: proper system sizing, integration with existing plumbing infrastructure, and comprehensive maintenance programs. ROI analysis indicates typical payback periods of 3-5 years for commercial installations, with some achieving positive returns in as little as 24 months.

Green Building Certification Integration

LEED and BREEAM Requirements

LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) represent the two most widely recognized sustainable building certification systems globally. Each framework establishes specific requirements across multiple categories that projects must meet to achieve certification.

LEED certification focuses on seven key areas: Location and Transportation, Sustainable Sites, Water Efficiency, Energy and Atmosphere, Materials and Resources, Indoor Environmental Quality, and Innovation. Projects earn points in each category, with certification levels ranging from Certified (40-49 points) to Platinum (80+ points). Energy efficiency typically carries the highest point potential, encouraging projects to implement comprehensive energy management strategies.

BREEAM assessment categories include Management, Health and Wellbeing, Energy, Transport, Water, Materials, Waste, Land Use and Ecology, and Pollution. The scoring system awards credits within each category, with final ratings from Pass to Outstanding. BREEAM places particular emphasis on lifecycle assessment and operational performance.

To align projects with these certification requirements, organizations should:

– Conduct preliminary assessments to identify achievable certification levels

– Integrate sustainability goals into early design phases

– Implement robust documentation processes

– Engage certified professionals for guidance

– Monitor and verify performance metrics throughout construction

Both systems require careful planning and coordination among project stakeholders. Success often depends on establishing clear sustainability targets during project inception and maintaining focus throughout implementation. Regular updates to both certification systems ensure alignment with evolving environmental standards and technological capabilities, requiring teams to stay current with requirements and best practices.

Cost-Benefit Analysis

Implementing environmental sustainability projects requires careful financial analysis to justify the initial investment and demonstrate long-term value. Our research shows that while certification costs and sustainable materials can increase upfront expenses by 2-8%, these investments typically generate positive returns within 3-5 years through reduced operational costs and increased property values.

Energy-efficient systems and sustainable building practices, when integrated with cost-effective project management, can reduce utility expenses by 25-35% annually. LEED-certified buildings command premium rental rates averaging 7.5% higher than conventional properties and maintain better occupancy rates.

Case studies from recent commercial developments demonstrate that green building certifications yield significant ROI:

– Energy-efficient HVAC systems: 15-20% reduction in energy costs

– Water conservation measures: 30-50% decrease in consumption

– Waste reduction programs: 40% lower disposal costs

– Solar panel installations: 8-12 year payback period with utility savings

Additional financial benefits include:

– Tax incentives and grants for sustainable construction

– Enhanced corporate reputation and marketing value

– Improved employee productivity in green workspaces

– Higher resale value (10-15% premium)

– Reduced maintenance and replacement costs

While initial certification costs range from $30,000 to $100,000 depending on project scope, the long-term financial advantages consistently outweigh these expenses. Organizations should conduct thorough lifecycle cost analyses to identify the most beneficial sustainability investments for their specific projects and operational goals.

As we look to the future of sustainable construction, it’s clear that environmental project management has evolved from a niche consideration to an essential business imperative. The successful implementation of sustainable practices requires a careful balance of environmental stewardship, economic viability, and social responsibility.

Throughout this exploration of environmental sustainability projects, we’ve seen how innovative approaches and technologies are reshaping the construction landscape. From advanced waste reduction strategies to renewable energy integration, the industry is embracing solutions that deliver both environmental and financial benefits.

Key success factors have emerged from our analysis: comprehensive stakeholder engagement, clear sustainability metrics, robust monitoring systems, and adaptable project frameworks. These elements, combined with proper risk management and resource optimization, form the foundation of successful sustainable construction projects.

Looking ahead, several trends will likely shape the future of sustainable project management. The increasing adoption of digital technologies, such as BIM and IoT sensors, will enhance our ability to monitor and optimize resource usage. Climate resilience will become a central consideration in project planning, while circular economy principles will drive material selection and waste management strategies.

For construction professionals, the path forward requires continued investment in sustainability education, technology adoption, and innovative practices. The business case for sustainable construction continues to strengthen, supported by regulatory requirements, market demands, and demonstrated ROI.

As we advance, the challenge lies not in whether to implement sustainable practices, but in how to maximize their effectiveness while maintaining project efficiency. Success will depend on our ability to integrate sustainability throughout the project lifecycle, from initial concept to final delivery and beyond.