Modern digital tools in construction management are fundamentally transforming how projects are conceived, executed, and delivered. Real-time collaboration platforms, artificial intelligence-driven analytics, and cloud-based project management solutions now enable construction professionals to achieve unprecedented levels of efficiency and control. Advanced Building Information Modeling (BIM) integration, combined with mobile-first applications, empowers teams to make data-driven decisions directly from the construction site, reducing delays and minimizing costly errors.

The construction industry’s rapid technological evolution demands a strategic approach to implementing these solutions. From automated progress tracking using drone technology to predictive analytics that forecast potential bottlenecks, today’s project management technologies offer construction leaders the tools to deliver projects on time and within budget. These innovations not only streamline workflows but also provide unprecedented visibility into project performance, resource allocation, and risk management.

The impact of these technological advancements extends beyond mere efficiency gains – they’re reshaping the very foundation of how construction projects are managed, monitored, and executed in the modern era.

Cloud-Based Collaboration Platforms Transform Site Management

Real-Time Data Sharing and Decision Making

Cloud-based platforms have revolutionized how construction teams share information and make critical decisions in real-time. These collaborative environments enable stakeholders across different locations to access, update, and analyze project data simultaneously, significantly reducing communication delays and potential misunderstandings.

Modern cloud solutions integrate various data streams, from BIM models and construction schedules to equipment tracking and material inventories. Project managers can monitor progress, identify potential bottlenecks, and make informed decisions based on real-time analytics. For instance, when design changes occur, all team members receive immediate notifications and can collaborate on solutions without the traditional back-and-forth of emails and meetings.

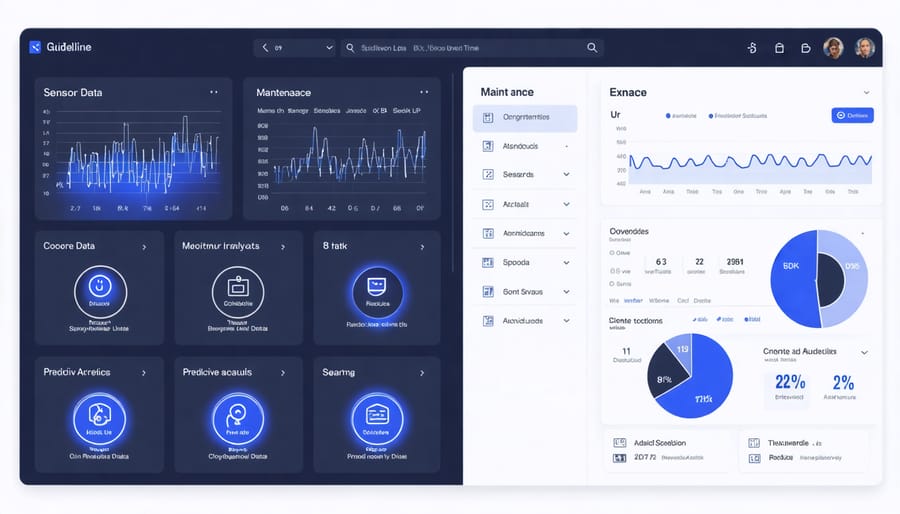

A notable advancement is the implementation of digital dashboards that provide customizable views of project metrics. These dashboards offer instant visibility into key performance indicators (KPIs), resource allocation, and project milestones. Decision-makers can drill down into specific aspects of the project, from budget tracking to workforce productivity, enabling quick response to emerging challenges.

Mobile compatibility has further enhanced real-time collaboration, allowing field teams to upload site photos, update task status, and report issues directly from their devices. This immediate feedback loop between office and field personnel ensures that potential problems are addressed promptly, reducing costly delays and rework.

The integration of artificial intelligence and machine learning algorithms helps predict potential issues before they occur, allowing teams to make proactive decisions rather than reactive ones. This predictive capability, combined with real-time data sharing, has become invaluable for maintaining project momentum and ensuring successful outcomes.

Mobile Integration for On-Site Excellence

Mobile technology has revolutionized construction project management by enabling real-time communication, data access, and decision-making directly from the job site. Today’s construction professionals leverage mobile applications to streamline workflows, enhance collaboration, and maintain constant connectivity with their teams and stakeholders.

Modern construction management apps offer comprehensive features including digital document management, real-time progress tracking, and instant issue reporting. Site supervisors can capture and annotate photos, update punch lists, and share critical information with office teams immediately, eliminating delays and reducing the risk of miscommunication.

Field teams benefit from mobile-optimized Building Information Modeling (BIM) viewers, allowing them to access and interact with 3D models on tablets and smartphones. This capability enables precise on-site verification and helps identify potential conflicts before they become costly problems.

Safety inspections and quality control processes have been transformed through mobile solutions. Digital checklists, automated compliance tracking, and instant incident reporting capabilities ensure better accountability and faster response times. Many platforms also integrate with wearable technology and IoT sensors, providing real-time environmental and safety monitoring.

Time and attendance tracking, equipment management, and material logistics have become more efficient through mobile solutions. Project managers can approve timesheets, track equipment usage, and manage deliveries directly from their mobile devices, ensuring smooth operations and better resource allocation. The integration of GPS functionality further enhances location-based services and site logistics management.

AI and Machine Learning in Project Planning

Predictive Analytics for Risk Management

Predictive analytics powered by artificial intelligence is revolutionizing risk management in construction projects. Recent advances in AI in construction management have enabled project managers to identify potential risks before they materialize, significantly reducing costly delays and safety incidents.

These sophisticated systems analyze historical project data, weather patterns, resource allocation trends, and real-time site conditions to forecast potential challenges. For example, machine learning algorithms can predict equipment failures by monitoring performance metrics, enabling preventive maintenance that keeps projects on schedule. Similarly, AI-driven analytics can assess weather impact probabilities and automatically suggest schedule adjustments to minimize disruptions.

Risk prediction models also evaluate contractor performance patterns, supply chain vulnerabilities, and market conditions to identify potential budget overruns. By processing thousands of data points simultaneously, these systems provide actionable insights that traditional risk assessment methods might miss. Project managers can then implement targeted mitigation strategies, such as adjusting resource allocation or modifying construction sequences.

Case studies have shown that construction firms implementing predictive analytics have reduced project delays by up to 20% and achieved cost savings between 15-25% through better risk management. The technology continues to evolve, with newer systems incorporating IoT sensor data and real-time environmental monitoring to provide increasingly accurate risk assessments.

Resource Optimization Through Machine Learning

Machine learning algorithms are revolutionizing resource optimization in construction project management, offering unprecedented accuracy in resource allocation and scheduling decisions. These sophisticated systems analyze historical project data, performance metrics, and real-time information to generate optimal resource distribution strategies.

By processing vast amounts of project data, ML algorithms can predict resource requirements with remarkable precision, helping project managers avoid both over-allocation and underutilization of assets. The technology considers multiple variables simultaneously, including worker availability, equipment capacity, material delivery schedules, and project dependencies, to create dynamic resource allocation plans that adapt to changing project conditions.

Advanced ML models excel at identifying patterns in resource usage across similar projects, enabling more accurate forecasting of labor needs and equipment deployment. For instance, these systems can predict peak demand periods for specific trades or machinery, allowing project managers to plan accordingly and minimize costly downtime.

Real-world applications have shown that ML-powered resource optimization can reduce resource-related delays by up to 20% and improve overall project efficiency by 15-25%. The technology also excels at risk assessment, flagging potential resource conflicts before they impact project timelines.

Construction firms implementing these solutions report significant improvements in project delivery times and cost management. The continuous learning capabilities of these systems mean they become more accurate over time, providing increasingly refined recommendations based on accumulated project data and outcomes.

BIM Integration with Project Management Tools

4D and 5D BIM Applications

4D and 5D BIM applications represent a significant advancement in construction project management, integrating temporal and financial dimensions into traditional 3D models. While 4D BIM incorporates scheduling and sequence planning, 5D BIM adds detailed cost management strategies and budget tracking capabilities.

In 4D applications, project teams can visualize construction sequences through time-linked simulations, enabling better coordination and workflow optimization. This capability allows stakeholders to identify potential conflicts and logistical challenges before they materialize on-site, significantly reducing costly delays and resource allocation issues.

The integration of 5D elements transforms BIM into a comprehensive financial planning tool. Project managers can generate accurate cost estimates, track expenses in real-time, and analyze the financial impact of design changes instantaneously. This dimensional enhancement enables quantity takeoffs to be automatically updated as the model evolves, ensuring cost projections remain current throughout the project lifecycle.

Recent implementations have demonstrated remarkable improvements in project outcomes. For instance, a major commercial development in Singapore reported a 15% reduction in schedule delays and a 12% cost saving through 4D and 5D BIM implementation. The technology enabled early detection of scheduling conflicts and more precise material quantity calculations.

The true power of 4D and 5D BIM lies in their synergistic relationship. When combined, these dimensions create a dynamic project management environment where time and cost implications of decisions are immediately visible. Project managers can evaluate multiple scenarios, optimize resource allocation, and make data-driven decisions with greater confidence.

Looking ahead, the integration of artificial intelligence and machine learning with 4D and 5D BIM promises even more sophisticated capabilities, including predictive analytics for schedule optimization and automated cost forecasting based on historical project data.

Digital Twin Technology for Project Oversight

Real-Time Project Monitoring

Digital twins have revolutionized project monitoring by creating virtual replicas of construction projects that update in real-time. These sophisticated systems integrate data from various sources, including IoT sensors, BIM models, and project management software, to provide comprehensive visibility into project progress and performance.

Construction teams can monitor multiple aspects simultaneously, from material consumption and equipment utilization to workforce productivity and safety compliance. Advanced sensors deployed throughout the construction site continuously transmit data to the digital twin platform, enabling project managers to track actual progress against planned schedules and identify potential issues before they impact the project timeline.

The technology’s predictive capabilities are particularly valuable for risk management. By analyzing patterns and trends in real-time data, digital twins can forecast potential delays, cost overruns, or quality issues. This proactive approach allows project teams to implement corrective measures promptly, maintaining project momentum and ensuring delivery targets are met.

Real-world applications have demonstrated significant benefits. For instance, a recent high-rise development project in Singapore reported a 20% reduction in construction delays after implementing digital twin monitoring. The system’s ability to coordinate multiple trades and optimize resource allocation proved crucial in maintaining project efficiency.

Integration with mobile devices enables stakeholders to access real-time project insights from anywhere, facilitating quick decision-making and improved collaboration among team members, regardless of their physical location. This level of transparency and accessibility has become increasingly important in modern construction management.

Predictive Maintenance and Asset Management

Digital twins have revolutionized how construction firms approach asset management and maintenance scheduling. These virtual replicas of physical assets enable real-time monitoring, predictive maintenance, and enhanced lifecycle management through sophisticated sensor networks and data analytics.

By implementing digital twin technology, project managers can track asset performance continuously, identifying potential issues before they escalate into costly failures. The system analyzes historical data patterns and current performance metrics to predict maintenance needs accurately, reducing downtime and extending equipment lifespan.

Construction companies utilizing digital twins report up to 30% reduction in maintenance costs and a 25% increase in asset reliability. For example, a major commercial development in Singapore implemented digital twin technology for its HVAC systems, resulting in a 20% decrease in energy consumption and significantly reduced maintenance interventions.

The technology integrates with Building Information Modeling (BIM) systems, creating a comprehensive asset management ecosystem. This integration enables facilities managers to access detailed component information, maintenance histories, and performance data through an intuitive interface.

Key benefits include:

– Real-time performance monitoring

– Automated maintenance scheduling

– Precise lifecycle cost forecasting

– Enhanced decision-making capabilities

– Improved resource allocation

As the technology continues to evolve, machine learning algorithms are being incorporated to further refine predictive capabilities, making asset management increasingly precise and cost-effective. This proactive approach to maintenance has become essential for modern construction projects, particularly in large-scale developments where asset reliability is crucial.

As we’ve explored throughout this comprehensive analysis, project management technologies have fundamentally transformed the construction industry, delivering unprecedented levels of efficiency, accuracy, and collaboration. The integration of Building Information Modeling (BIM), cloud-based platforms, and artificial intelligence has created a new paradigm in construction project management, enabling real-time decision-making and enhanced risk mitigation.

The impact of these technological advances extends beyond mere operational improvements. Construction firms implementing these solutions report significant reductions in project delays, cost overruns, and communication gaps. Industry data suggests that organizations utilizing integrated project management technologies experience up to 25% improvement in project delivery times and 20% reduction in overall project costs.

Looking ahead, the construction industry stands at the cusp of even more revolutionary changes. Emerging technologies such as digital twins, autonomous construction equipment, and advanced analytics powered by machine learning are poised to further optimize project management processes. The incorporation of Internet of Things (IoT) sensors and real-time monitoring systems will enable predictive maintenance and enhanced safety protocols, while augmented reality tools will revolutionize on-site coordination and quality control.

However, successful implementation of these technologies requires careful consideration of organizational readiness, staff training, and integration with existing systems. Construction firms must develop comprehensive digital transformation strategies that align with their specific needs and capabilities while ensuring robust cybersecurity measures.

As we move forward, the key to maximizing the benefits of project management technologies lies in fostering a culture of innovation and continuous learning. Organizations that invest in both technological infrastructure and human capital development will be best positioned to leverage these tools effectively and maintain competitive advantage in an increasingly digital construction landscape.

The future of construction project management will be defined by greater automation, enhanced data-driven decision-making, and seamless integration across all project phases. Companies that embrace these technological advances while maintaining focus on practical implementation and return on investment will lead the industry’s evolution toward more efficient, sustainable, and profitable operations.