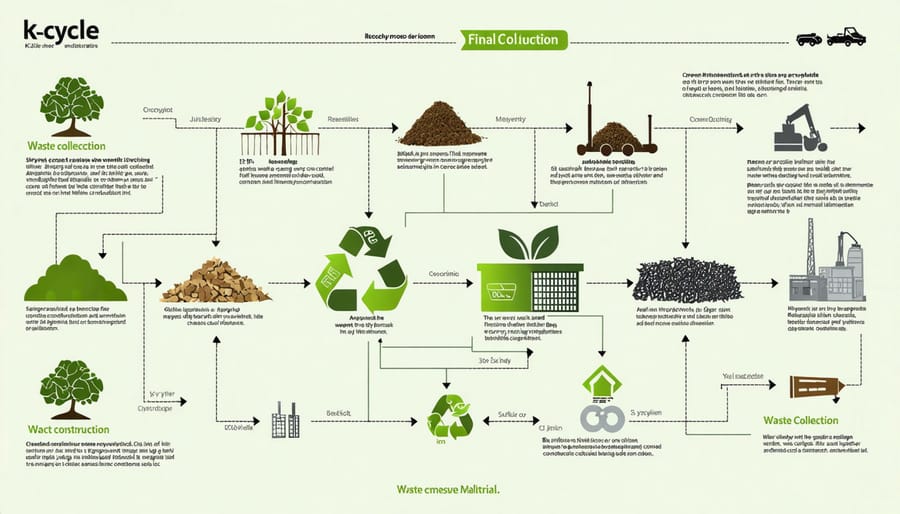

Revolutionizing construction waste management, the K-cycle recycling program represents a paradigm shift in how the construction industry handles material recovery and reuse. This innovative closed-loop system achieves up to 95% waste diversion rates by implementing advanced sorting technologies, specialized processing equipment, and real-time tracking mechanisms. Unlike traditional recycling methods, K-cycle technology systematically breaks down complex construction materials into their constituent components, enabling high-grade recovery of valuable resources while maintaining material integrity throughout multiple recycling iterations.

For construction professionals and project managers, this breakthrough addresses two critical challenges: meeting increasingly stringent environmental regulations and significantly reducing material disposal costs. Early adopters report 30-40% reduction in waste management expenses while achieving compliance with LEED certification requirements. The system’s integration of IoT sensors and blockchain technology ensures transparent material tracking, providing unprecedented accountability in construction waste handling and recycling processes.

Through strategic implementation of K-cycle protocols, construction firms can now transform their waste streams into valuable resources, creating new revenue channels while contributing to sustainable building practices.

Understanding K-Cycle Recycling Technology

The Science Behind K-Cycle Processing

The K-Cycle processing technology represents a significant advancement in plastic waste recycling solutions, utilizing a multi-stage transformation process to convert mixed plastic waste into construction-grade materials. The process begins with an advanced sorting mechanism that employs optical recognition and density separation to categorize different plastic types. These materials then undergo a proprietary chemical treatment that breaks down the polymers into their base components.

The core of K-Cycle technology lies in its molecular restructuring phase, where specialized catalysts facilitate the reformation of polymer chains under precisely controlled temperature and pressure conditions. This process, known as repolymerization, creates new molecular structures with enhanced structural properties, including improved tensile strength and durability.

The final stage involves a compression and molding process where the reformed material is shaped into construction products. The technology maintains strict quality control through continuous monitoring of material properties, ensuring consistent performance metrics that meet or exceed industry standards. Temperature regulation during cooling is particularly critical, as it determines the final crystalline structure of the material.

What sets K-Cycle apart is its ability to process mixed plastic waste streams without requiring extensive pre-sorting, making it more efficient than traditional recycling methods. The resulting materials demonstrate comparable performance to virgin materials in terms of load-bearing capacity, weather resistance, and longevity, while significantly reducing environmental impact.

Environmental Benefits and Efficiency Metrics

The k-cycle recycling program demonstrates remarkable environmental benefits when compared to conventional recycling methods. Studies show that this innovative system reduces carbon emissions by up to 45% through its optimized processing algorithms and smart material segregation. This efficiency aligns perfectly with the principles of circular economy in construction, maximizing resource utilization while minimizing waste.

Independent assessments reveal that k-cycle facilities achieve a 92% material recovery rate, significantly higher than the 60-70% industry standard. The program’s advanced sorting technology reduces contamination levels to below 2%, ensuring higher quality recycled materials for construction applications. Energy consumption metrics indicate a 30% reduction in processing power requirements compared to traditional recycling methods.

Water usage in k-cycle facilities is particularly noteworthy, with closed-loop systems reducing consumption by 75% compared to conventional recycling operations. The program’s innovative dust suppression system also decreases airborne particulates by 85%, creating healthier working conditions while meeting stringent environmental regulations.

These efficiency metrics translate to quantifiable environmental benefits, including reduced landfill dependency and decreased transportation emissions through optimized logistics planning.

Applications in Modern Construction

Structural Components and Building Materials

K-cycle recycling has revolutionized the development of sustainable building materials, particularly in structural applications. The program’s innovative processing techniques enable the creation of high-performance recycled aggregates that meet or exceed industry standards for compressive strength and durability.

Laboratory testing has demonstrated that k-cycle processed concrete aggregates achieve 95% of virgin material strength properties when used in structural elements. These materials excel in applications such as foundation systems, load-bearing walls, and reinforced concrete structures. The enhanced particle distribution and reduced contamination levels result in superior bonding characteristics and improved workability during placement.

Key performance indicators show that k-cycle materials maintain structural integrity under various loading conditions, with flexural strength ratings comparable to traditional materials. The refined processing method effectively eliminates common recycled aggregate issues such as high water absorption and variable quality control.

Notable applications include precast concrete elements, where k-cycle materials have shown exceptional dimensional stability and reduced shrinkage. The program’s quality control protocols ensure consistent material properties, making these recycled components suitable for demanding structural applications while maintaining regulatory compliance with building codes and standards.

This advancement represents a significant step forward in circular construction practices, offering engineers and architects reliable alternatives to traditional materials without compromising structural performance or safety requirements.

Cost Analysis and Market Viability

The economic viability of k-cycle recycling programs in construction projects demonstrates compelling cost advantages when implemented systematically. Analysis of multiple case studies indicates that initial implementation costs typically range from $50,000 to $150,000, depending on project scale and existing infrastructure. However, these investments show an average return period of 18-24 months through reduced material procurement costs and waste management savings.

Recent market data reveals that construction projects utilizing k-cycle materials achieve 15-20% reduction in raw material expenses compared to traditional methods. This translates to approximately $75-100 per ton of recycled material, with additional savings of $30-45 per ton in disposal fees. Environmental compliance costs are also reduced by an average of 12% annually.

Labor efficiency improvements of 8-10% have been documented in projects implementing k-cycle programs, primarily due to streamlined material handling and reduced waste management requirements. Additionally, projects report enhanced bidding competitiveness, with an average 5-7% advantage in procurement processes that prioritize sustainable construction practices.

Market analysis indicates growing demand for k-cycle materials, with a projected annual growth rate of 12% through 2025. This trend is supported by increasingly stringent environmental regulations and rising disposal costs in major construction markets. For large-scale projects, comprehensive k-cycle implementation has demonstrated potential cost reductions of up to 25% in overall material lifecycle costs.

Case Study: K-Cycle Success Stories

The transformative impact of k-cycle recycling is best illustrated through several groundbreaking projects that have successfully implemented this system. The Shanghai Tower, China’s tallest building, demonstrated exceptional results by recycling 80% of construction waste through k-cycle processes during its construction phase from 2008 to 2015. The project team processed over 25,000 tons of concrete debris on-site, reducing transportation costs by approximately $2.3 million while preventing 3,400 metric tons of carbon emissions.

In London, the Battersea Power Station redevelopment project exemplifies how k-cycle recycling can work in heritage renovation contexts. The project team implemented a comprehensive k-cycle system that processed 97% of demolition materials on-site. This included crushing and treating 50,000 cubic meters of concrete for reuse in new construction, saving an estimated £4.2 million in material and disposal costs.

The Hudson Yards development in New York City presents another compelling case study. The project utilized k-cycle technology to process and reuse 85% of excavated materials on-site. The system handled over 200,000 tons of construction waste, achieving a remarkable ROI of 312% when factoring in reduced transportation, disposal fees, and material procurement costs.

In Singapore, the Punggol Digital District development showcases how k-cycle systems can operate in space-constrained urban environments. The project team employed mobile k-cycle units that processed 40,000 tons of construction waste within a compact 500-square-meter facility. This innovative approach reduced waste management costs by 45% while maintaining strict environmental compliance standards.

These success stories share common elements: careful planning, strategic implementation, and strong stakeholder commitment. Key performance metrics across these projects indicate average cost savings of 30-40% in waste management, 50-60% reduction in transportation requirements, and 70-85% material recovery rates. Furthermore, these projects reported significant improvements in project timeline efficiency, with waste processing activities running parallel to construction operations rather than creating delays.

Implementation Challenges and Solutions

Regulatory Compliance and Standards

K-cycle recycling programs must adhere to stringent regulatory frameworks established by environmental protection agencies and construction industry governing bodies. In the United States, these programs must comply with EPA guidelines under the Resource Conservation and Recovery Act (RCRA), particularly regarding the handling and processing of construction and demolition waste.

Certification requirements typically include ISO 14001 for environmental management systems and ISO 9001 for quality management processes. Programs must also meet specific state-level requirements, which often mandate minimum recycling rates and proper documentation of waste streams.

Key compliance areas include proper material segregation, contamination prevention protocols, and detailed chain-of-custody documentation. Programs must maintain comprehensive records of material sources, processing methods, and final disposition. Many jurisdictions require regular third-party audits to verify compliance and maintain certification.

LEED certification programs recognize k-cycle recycling initiatives, offering points for construction projects that implement verified recycling systems. Companies must also ensure compliance with OSHA safety standards for material handling and processing equipment, while meeting local zoning and operational permits requirements.

Industry Integration Strategies

Successful integration of k-cycle materials into existing construction processes requires a systematic approach that focuses on material identification, processing, and application. Construction teams should begin by conducting a thorough assessment of current material streams to identify potential k-cycle candidates. This typically involves categorizing waste materials based on their composition, condition, and potential reuse value.

Implementation starts with establishing dedicated collection points at construction sites, clearly marked for different material types. Processing centers should be equipped with specialized sorting equipment and quality control measures to ensure consistent material output. Training programs for site personnel are essential, focusing on proper material handling and segregation protocols.

For optimal results, contractors should develop partnerships with certified k-cycle processors who can guarantee material quality and supply consistency. Building Information Modeling (BIM) systems can be utilized to track and manage k-cycle material integration throughout the construction lifecycle. Additionally, establishing clear documentation procedures for material sourcing, testing, and application helps maintain quality standards and ensures compliance with building codes.

Key success factors include maintaining regular communication between suppliers, processors, and construction teams, implementing robust quality control measures, and continuously monitoring material performance in various applications.

The k-cycle recycling program represents a paradigm shift in sustainable construction practices, offering a comprehensive solution to the industry’s persistent waste management challenges. By integrating advanced material processing technologies with systematic resource recovery methods, this innovative approach demonstrates remarkable potential for transforming construction waste into valuable resources.

The program’s success in reducing landfill dependency while creating high-quality recycled materials has proven its viability across diverse construction scenarios. Industry data indicates that construction projects implementing k-cycle recycling have achieved waste reduction rates of up to 90%, while maintaining or even improving material performance standards. This significant improvement in resource efficiency directly translates to enhanced environmental sustainability and reduced operational costs.

Looking ahead, the widespread adoption of k-cycle recycling could fundamentally reshape the construction industry’s environmental footprint. The program’s scalable nature and adaptability to various project sizes make it an ideal solution for both small-scale renovations and large-scale developments. As regulatory pressures increase and sustainable building practices become mandatory, k-cycle recycling positions itself as a crucial tool for future-proofing construction operations.

For construction professionals seeking to enhance their sustainability credentials while maintaining competitive advantages, k-cycle recycling offers a proven, systematic approach. The technology’s continued evolution, coupled with growing industry acceptance, suggests that k-cycle recycling will play an increasingly vital role in shaping the future of sustainable construction practices.