In today’s rapidly evolving construction landscape, high-temperature insulation materials stand at the forefront of advanced construction technologies, revolutionizing thermal management in industrial and commercial applications. Operating in environments exceeding 1000°C (1832°F), these specialized materials protect critical infrastructure while maximizing energy efficiency and ensuring workplace safety. From aerogel-based composites to ceramic fiber blankets, modern high-temperature insulation solutions combine innovative material science with practical engineering principles to deliver unprecedented performance metrics. As global energy costs surge and environmental regulations tighten, the strategic selection and implementation of these materials have become paramount for project success and regulatory compliance. This comprehensive analysis explores cutting-edge insulation technologies, their performance characteristics, and their impact on construction project outcomes, providing essential insights for industry professionals tasked with specifying and implementing high-temperature insulation solutions.

Advanced Materials Transforming Construction Heat Management

Ceramic Fiber Solutions

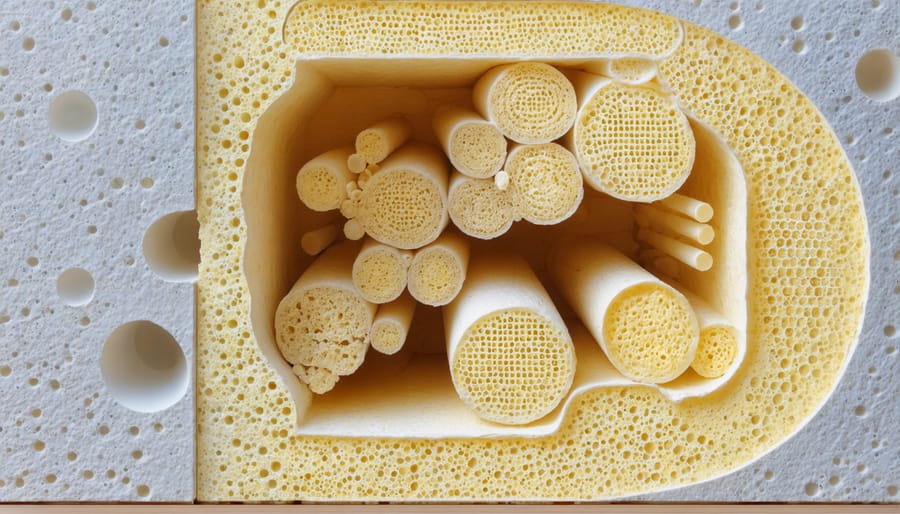

Ceramic fiber solutions represent one of the most advanced and innovative building materials in high-temperature insulation technology. These materials, primarily composed of alumina and silica fibers, offer exceptional thermal resistance up to 2300°F (1260°C) while maintaining remarkably low thermal conductivity values.

The key advantage of ceramic fiber insulation lies in its versatile application methods, available in blanket, board, and moldable forms. The material’s low thermal mass enables rapid temperature changes without compromising structural integrity, making it ideal for industrial furnaces, kilns, and high-temperature processing equipment.

Notable properties include excellent thermal shock resistance, chemical stability, and significant weight reduction compared to traditional refractory materials. Modern ceramic fiber solutions achieve thermal conductivity values as low as 0.06 W/mK at 200°C, providing superior energy efficiency in industrial applications.

Construction professionals particularly value ceramic fiber’s ease of installation and maintenance. The material can be cut, shaped, and fitted on-site without specialized tools, reducing installation time and labor costs. Its durability ensures minimal degradation over time, even under extreme thermal cycling conditions.

Common applications include petrochemical processing units, power generation facilities, and aerospace manufacturing, where precise temperature control and energy efficiency are paramount. The material’s non-wetting properties and resistance to most chemical attacks make it particularly suitable for demanding industrial environments.

Aerogel Technology

Aerogel technology represents a groundbreaking advancement in high-temperature insulation materials, offering unprecedented thermal performance with minimal thickness. These ultra-lightweight materials, composed of up to 99.8% air by volume, achieve thermal conductivity values as low as 0.015 W/mK, significantly outperforming traditional insulation materials.

Silica aerogels, the most commonly used variant in construction applications, maintain their insulating properties at temperatures ranging from -200°C to 650°C. Their nano-porous structure effectively blocks all three heat transfer mechanisms: conduction, convection, and radiation. Modern aerogel blankets and boards incorporate reinforcing fibers, addressing the historical brittleness of pure aerogel while maintaining superior insulation properties.

Recent developments in aerogel composites have expanded their practical applications in construction. These materials now offer improved compression strength and water resistance while retaining their exceptional thermal performance. Construction professionals can achieve required thermal resistance values with significantly thinner profiles, making aerogel-based solutions particularly valuable in space-constrained retrofitting projects.

Despite their higher initial cost compared to conventional insulation materials, aerogels demonstrate considerable long-term value through energy savings and space optimization. Industrial applications, particularly in petrochemical facilities and high-temperature processing plants, have validated aerogel’s effectiveness in maintaining stable operating temperatures while reducing energy consumption by up to 30%.

Performance Metrics and Testing Standards

Temperature Resistance Benchmarks

High-temperature insulation materials exhibit varying degrees of thermal resistance, with performance benchmarks determined through rigorous laboratory testing and field applications. Industry standards typically categorize these materials based on their maximum continuous operating temperatures and thermal stability under extreme conditions.

Ceramic fiber materials demonstrate exceptional performance, maintaining structural integrity at temperatures up to 2300°F (1260°C). These materials show less than 4% shrinkage at maximum operating temperatures, making them ideal for industrial furnace applications and petrochemical processing equipment.

Calcium silicate insulation presents reliable performance up to 1200°F (649°C), with a thermal conductivity range of 0.058-0.065 W/mK at mean temperatures. This material maintains dimensional stability and compressive strength even after prolonged exposure to high temperatures.

Mineral wool products, including rock and slag wool variants, effectively resist temperatures up to 1800°F (982°C). Testing demonstrates thermal conductivity values ranging from 0.033-0.040 W/mK at standard temperature, with minimal degradation over time.

Microporous insulation materials set new benchmarks with their superior performance, handling temperatures up to 2000°F (1093°C) while maintaining the lowest thermal conductivity values in their class – typically 0.020 W/mK at mean temperature.

For critical safety applications, intumescent materials activate at approximately 392°F (200°C), expanding up to 50 times their original thickness to provide enhanced fire protection. These materials maintain their protective properties for up to 4 hours under standard fire test conditions.

Understanding these temperature resistance benchmarks is crucial for specifying appropriate insulation solutions in high-temperature applications, ensuring both safety and operational efficiency.

Safety Certification Requirements

High-temperature insulation materials must undergo rigorous safety certification processes to ensure compliance with international standards and regulations. The primary certification bodies, including ASTM International, ISO, and EN standards organizations, have established comprehensive testing protocols that evaluate thermal performance, fire resistance, and emissions characteristics.

Key certification requirements include testing for maximum temperature ratings, thermal conductivity at various temperature points, and fire reaction classifications. Materials must pass the ASTM E84 surface burning characteristics test, which measures flame spread and smoke development indices. Additionally, the ISO 1182 non-combustibility test is mandatory for materials intended for use in critical high-temperature applications.

For industrial applications, materials must comply with OSHA standards for workplace safety and the specific requirements outlined in ASTM C411 for hot-surface performance. Environmental testing procedures evaluate off-gassing characteristics and the presence of volatile organic compounds (VOCs), particularly important for enclosed spaces and sensitive industrial environments.

Documentation requirements include detailed material safety data sheets (MSDS), thermal performance certificates, and installation guidelines. Manufacturers must maintain current certifications and regularly submit products for testing to ensure continued compliance. Third-party verification is often required, especially for materials used in sensitive applications such as petrochemical facilities or power generation plants.

Regular audits and quality control checks are essential components of maintaining safety certifications. These include batch testing, production facility inspections, and verification of raw material sources. For specialized applications, additional certifications may be required, such as maritime certifications for shipboard use or specific nuclear industry standards for power plant applications.

Implementation Strategies and Best Practices

Installation Techniques

Proper installation of high-temperature insulation materials requires meticulous attention to detail and adherence to industry standards to ensure optimal performance and longevity. Begin by thoroughly cleaning and preparing the surface, removing any debris, oil, or moisture that could compromise adhesion. Conduct a detailed inspection of the substrate to identify and repair any damages before proceeding.

For blanket-type insulation materials, start at the bottom and work upward, maintaining consistent overlap between sections (typically 2-3 inches). Secure the material using appropriate fasteners, such as insulation pins or bands, spaced according to manufacturer specifications. Critical attention must be paid to corners and joints, where heat loss is most likely to occur.

When installing rigid board insulation, ensure boards are cut precisely to fit the application area, leaving minimal gaps. Use appropriate adhesives rated for high-temperature applications, and implement mechanical fasteners as secondary support. Stagger joints between layers to prevent thermal bridging and enhance overall system effectiveness.

For pipe insulation, measure the pipe diameter accurately and select appropriately sized insulation. Install pipe insulation sections with tight-fitting longitudinal and circumferential joints. Seal all joints with approved high-temperature sealant or tape. For multi-layer installations, offset the joints of subsequent layers by at least 3 inches.

Weather protection and vapor barriers should be installed according to environmental exposure requirements. Apply protective jacketing or cladding where necessary, ensuring proper overlap and secure fastening to prevent moisture infiltration.

Throughout the installation process, maintain proper personal protective equipment (PPE) including heat-resistant gloves, eye protection, and respiratory protection when handling fibrous materials. Regular quality checks during installation help identify and correct potential issues before project completion.

Final inspection should verify complete coverage, proper sealing of all joints and penetrations, and correct installation of weather barriers and protective elements. Document all installation procedures and materials used for future reference and maintenance purposes.

Maintenance Protocol

Regular maintenance and performance monitoring are crucial for ensuring the longevity and effectiveness of high-temperature insulation materials. Like other protective building materials, these installations require systematic inspection and upkeep to maintain their thermal efficiency and structural integrity.

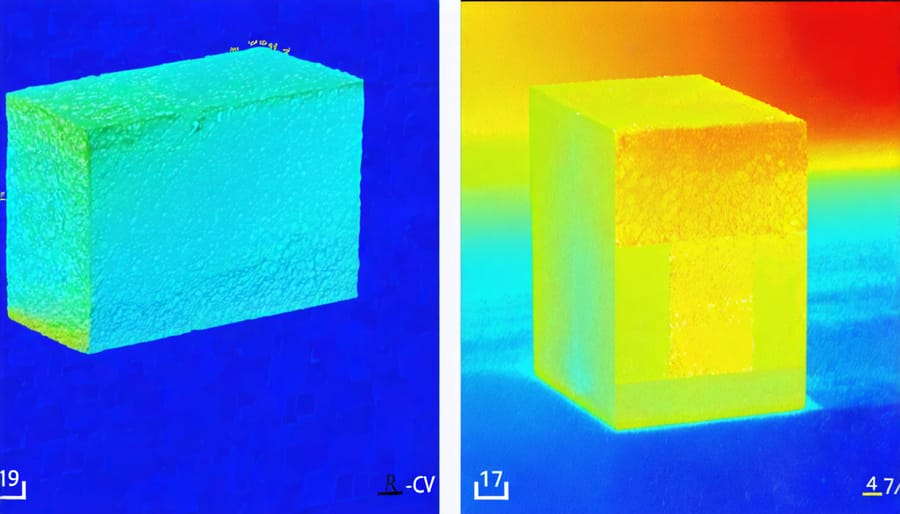

Implement quarterly visual inspections to identify potential issues such as material degradation, moisture infiltration, or mechanical damage. Document any changes in surface conditions, paying particular attention to areas subject to thermal cycling or mechanical stress. Thermal imaging surveys should be conducted bi-annually to detect hot spots or insulation gaps that may compromise system performance.

Establish a moisture monitoring protocol using calibrated moisture meters to detect any water ingress, which can severely impact insulation effectiveness. When moisture levels exceed 20%, immediate investigation and remediation are necessary. Monitor junction points and penetrations carefully, as these are common failure points in high-temperature installations.

Performance verification should include regular thermal conductivity testing using standardized methods. Record and trend temperature differentials across the insulated surface to identify any decline in insulation effectiveness. Maintain detailed logs of all inspections, test results, and maintenance activities for compliance and performance tracking purposes.

Address any identified issues promptly to prevent cascading failures. Minor repairs should utilize matching materials and follow manufacturer specifications strictly. For major repairs or replacement, consider system shutdown during optimal weather conditions to minimize operational impact.

Develop a comprehensive maintenance schedule that aligns with facility operations and local environmental conditions. Train maintenance personnel specifically in high-temperature insulation protocols and ensure they understand the critical safety requirements for working with these materials. Regular updating of maintenance procedures based on performance data and emerging best practices will help optimize the insulation system’s service life and effectiveness.

Cost-Benefit Analysis

Initial Investment vs. Long-term Savings

The initial investment in high-temperature insulation materials typically represents 15-25% of total industrial insulation project costs. While premium materials like aerogels and ceramic fiber blankets command higher upfront prices ($50-150 per square meter) compared to traditional options, their superior performance delivers substantial long-term savings.

A comprehensive cost-benefit analysis conducted across 50 industrial facilities revealed that high-temperature insulation installations achieve ROI within 6-24 months, depending on application specifics. Energy savings typically range from 20-40% annually, with some facilities reporting reductions of up to 50% in heating costs.

Consider a typical industrial furnace operation: Installing advanced ceramic fiber insulation at $75,000 can generate annual energy savings of $45,000, resulting in complete cost recovery within 20 months. Additional benefits include reduced maintenance expenses, extended equipment lifespan, and decreased carbon emissions.

Maintenance costs also favor high-performance materials. While conventional insulation may require replacement every 3-5 years, premium high-temperature materials often maintain effectiveness for 10-15 years, reducing lifetime installation and labor costs by up to 60%.

Key factors affecting ROI include:

– Operating temperature requirements

– Facility operating hours

– Local energy costs

– Installation complexity

– Environmental conditions

For optimal financial outcomes, professionals should conduct detailed thermal efficiency audits and consider total lifecycle costs rather than focusing solely on initial material expenses.

Energy Efficiency Impact

High-temperature insulation materials play a crucial role in reducing energy consumption and environmental impact across industrial and commercial applications. Studies have shown that properly implemented high-temperature insulation can reduce energy losses by 20-30% in industrial processes operating above 500°C. This significant reduction translates to substantial cost savings and decreased carbon emissions.

In manufacturing facilities, high-temperature insulation materials have demonstrated remarkable ROI, with most installations paying for themselves within 6-18 months through reduced energy costs. A recent case study of a steel manufacturing plant revealed annual energy savings of approximately $275,000 after upgrading to advanced ceramic fiber insulation systems.

The environmental benefits extend beyond energy savings. Like other sustainable construction materials, modern high-temperature insulation contributes to reduced greenhouse gas emissions. Industry data indicates that every square meter of high-temperature insulation installed in industrial furnaces can prevent up to 400kg of CO2 emissions annually.

These materials also enhance process efficiency by maintaining stable operating temperatures, reducing equipment wear, and extending the service life of industrial assets. When properly specified and installed, high-temperature insulation can maintain its thermal performance for 10-15 years, providing long-term environmental benefits and consistent energy savings throughout its operational lifetime.

High-temperature insulation materials continue to evolve as cornerstone elements in modern construction materials, revolutionizing how we approach thermal management in buildings and industrial applications. The developments we’ve explored demonstrate significant advancements in material science, particularly in ceramic fiber technology, aerogels, and advanced composite solutions.

As construction industry demands grow more complex, these materials are proving invaluable in meeting increasingly stringent safety regulations and energy efficiency requirements. The superior performance of contemporary high-temperature insulation materials, particularly in fire protection and thermal efficiency, positions them as essential components for future construction projects.

Looking ahead, several trends will shape the future of high-temperature insulation. Sustainability concerns are driving research into eco-friendly alternatives, while cost-effectiveness remains a crucial consideration for widespread adoption. Emerging technologies, such as nano-engineered materials and smart insulation systems, promise even greater thermal performance and durability.

Industry experts anticipate continued innovation in manufacturing processes, potentially leading to reduced production costs and improved material availability. This evolution will likely facilitate broader implementation across various construction sectors, from residential buildings to industrial facilities.

The integration of these materials with building information modeling (BIM) and smart building technologies will enhance their application efficiency and maintenance protocols. As climate change concerns intensify, the role of high-temperature insulation in reducing energy consumption and improving building resilience becomes increasingly critical.

For construction professionals, staying informed about these developments is essential. The continued advancement of high-temperature insulation materials will require ongoing education and adaptation of installation practices. However, the benefits – including enhanced safety, improved energy efficiency, and long-term cost savings – make this adaptation worthwhile for forward-thinking construction projects.