Project advancement in modern construction demands a radical shift from traditional management approaches to data-driven, integrated solutions. Leading construction firms are achieving 30-40% faster project completion rates by leveraging advanced project controls, real-time analytics, and collaborative technologies that transform how teams operate on-site and remotely.

Digital transformation stands at the forefront of project advancement, with Building Information Modeling (BIM) and cloud-based project management platforms enabling unprecedented levels of coordination and efficiency. These technologies not only streamline workflows but also provide crucial predictive insights that help teams anticipate and resolve potential bottlenecks before they impact project timelines.

The construction industry’s evolution toward smart project advancement encompasses three critical pillars: integrated digital ecosystems that connect all stakeholders in real-time, automated progress monitoring systems that leverage AI and IoT sensors, and advanced risk management protocols that protect project investments. Forward-thinking organizations implementing these solutions report significant improvements in project delivery times, cost efficiency, and stakeholder satisfaction.

This comprehensive examination explores cutting-edge methodologies and technologies driving project advancement in contemporary construction management, offering practical insights for industry professionals seeking to optimize their project delivery systems.

Digital Twin Technology: The Virtual Blueprint Revolution

Real-time Project Monitoring

Modern construction projects are increasingly leveraging IoT (Internet of Things) sensors and real-time data analytics to transform project monitoring capabilities. These advanced systems, working in conjunction with construction drawing management systems, provide unprecedented visibility into project progress and site conditions.

IoT sensors strategically placed throughout construction sites continuously collect vital data on equipment utilization, material movement, environmental conditions, and worker safety parameters. These sensors transmit data to centralized platforms where advanced analytics engines process the information in real-time, enabling immediate response to potential issues.

Key benefits include:

– Automatic progress tracking against planned schedules

– Early detection of safety hazards and environmental risks

– Equipment performance monitoring and predictive maintenance

– Real-time material inventory management

– Environmental condition monitoring for optimal concrete curing

– Labor productivity analysis and resource optimization

Implementation of these systems typically involves a network of wireless sensors, edge computing devices, and cloud-based analytics platforms. Success stories from major construction firms demonstrate ROI through reduced delays, improved resource allocation, and enhanced safety compliance. For instance, a recent high-rise project in Singapore reported a 23% reduction in schedule delays after implementing comprehensive IoT monitoring.

Project managers can access this information through mobile dashboards, enabling informed decision-making from any location. This technological advancement represents a significant shift from traditional periodic inspections to continuous, data-driven project oversight.

Predictive Maintenance and Risk Management

Digital twins have revolutionized predictive maintenance and risk management in construction projects, offering unprecedented capabilities for issue prevention and strategic decision-making. These virtual replicas of physical assets enable project teams to simulate various scenarios and identify potential problems before they materialize on the actual construction site.

By leveraging real-time data from IoT sensors and advanced analytics, digital twins continuously monitor critical project components and systems. This proactive approach allows project managers to detect early warning signs of equipment failure, structural stress, or schedule conflicts. For instance, a major commercial development in Singapore utilized digital twin technology to predict maintenance needs for its HVAC systems, resulting in a 30% reduction in unexpected downtime.

The risk management capabilities extend beyond equipment maintenance. Digital twins enable teams to conduct virtual stress tests, analyze environmental impacts, and evaluate the consequences of proposed changes without physical implementation. This virtual testing environment significantly reduces the likelihood of costly mistakes and safety incidents.

Project managers can also use these digital models to optimize resource allocation and maintenance schedules. By analyzing historical data and performance patterns, the system can recommend optimal timing for preventive maintenance activities, ensuring minimal disruption to project timelines while maximizing equipment lifespan and operational efficiency.

The integration of artificial intelligence further enhances these predictive capabilities, learning from past incidents to improve future risk assessments and maintenance recommendations.

AI-Powered Project Optimization

Machine Learning for Resource Allocation

Machine learning algorithms are revolutionizing resource allocation in construction project management, offering unprecedented accuracy in predicting resource needs and optimizing their distribution. These intelligent systems analyze historical project data, current workflow patterns, and real-time site conditions to make informed decisions about personnel deployment, equipment utilization, and material management.

By implementing ML-powered resource allocation systems, project managers can achieve up to 30% improvement in resource efficiency. These systems excel at identifying potential bottlenecks before they occur and automatically suggesting redistributions of resources to maintain optimal project flow. For example, they can predict labor requirements for specific tasks based on project complexity, weather conditions, and site accessibility.

The technology also excels in equipment scheduling optimization, ensuring maximum utilization of expensive machinery while minimizing idle time. Advanced algorithms can forecast maintenance needs, coordinate equipment sharing between project sites, and adjust schedules based on real-time progress updates.

Material management benefits significantly from machine learning applications, with systems capable of predicting material requirements with remarkable accuracy. This capability helps prevent both shortages and excess inventory, reducing storage costs and minimizing waste. The technology can also optimize delivery schedules by considering factors such as supplier lead times, site storage capacity, and installation sequences.

Recent case studies demonstrate that companies implementing ML-based resource allocation systems typically achieve 15-20% cost savings while significantly reducing project delays caused by resource misallocation.

Automated Progress Tracking

Modern construction projects are increasingly leveraging AI-powered systems for automated progress tracking, revolutionizing how project advancement is monitored and reported. These sophisticated platforms utilize computer vision, IoT sensors, and machine learning algorithms to provide real-time insights into construction activities.

Advanced imaging technology, including drones and fixed cameras, captures detailed visual data of construction sites. This data is processed through AI algorithms that compare actual progress against BIM models and project schedules, automatically identifying deviations and potential delays. The system can detect completed work, measure installed quantities, and verify construction quality with minimal human intervention.

IoT sensors deployed across the site continuously monitor various parameters such as equipment utilization, material movement, and worker productivity. This data streams into centralized dashboards, offering project managers comprehensive visibility into site operations. The AI system analyzes these metrics to generate accurate progress reports, forecast completion dates, and flag potential bottlenecks.

Machine learning algorithms enhance the system’s capabilities over time, learning from historical data to improve prediction accuracy and decision-making support. The automated tracking system can integrate with project management software, enabling seamless updates to schedules, resource allocation, and cost projections.

Case studies have shown that automated progress tracking can reduce reporting time by up to 80% while significantly improving accuracy. This technology enables proactive project management, allowing teams to address issues before they impact project timelines or budgets.

Cloud-Based Collaboration Platforms

Real-time Documentation and Version Control

In today’s fast-paced construction environment, maintaining accurate and accessible project documentation is crucial for successful project advancement. Modern digital construction management tools have revolutionized how teams track, store, and share project information in real-time.

Cloud-based documentation systems enable simultaneous access and editing capabilities, ensuring all stakeholders work with the most current information. Version control features maintain a detailed history of changes, allowing teams to track modifications, identify authors, and revert to previous versions when necessary. This systematic approach minimizes errors, reduces conflicts, and strengthens accountability throughout the project lifecycle.

Real-time documentation also facilitates improved decision-making by providing instant access to critical project data, specifications, and regulatory compliance requirements. Integration with Building Information Modeling (BIM) systems further enhances documentation accuracy by linking project documents directly to 3D model elements.

Implementation of automated documentation workflows streamlines processes such as RFIs, submittals, and change orders. This automation not only saves time but also creates standardized audit trails that protect stakeholders and support potential dispute resolution. Regular backups and secure storage ensure project documentation remains protected and readily available for future reference.

Stakeholder Communication Enhancement

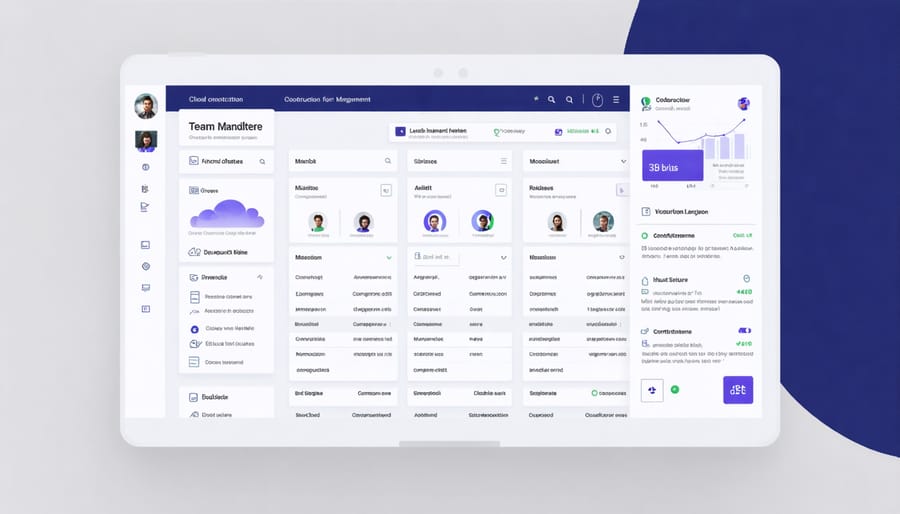

Effective stakeholder communication remains a cornerstone of successful project advancement in the construction industry. By implementing structured communication protocols and leveraging digital collaboration platforms, project teams can significantly enhance transparency and streamline information flow among all parties involved.

Real-time reporting dashboards and cloud-based document management systems enable stakeholders to access crucial project data, updates, and performance metrics instantly. This immediate access to information helps prevent misunderstandings, reduces delays in decision-making, and ensures all team members work with the most current project information.

Regular stakeholder engagement sessions, both virtual and in-person, facilitate open dialogue and prompt issue resolution. These meetings should follow a structured format, with clear agendas and documented outcomes that are accessible to all relevant parties. Construction firms implementing comprehensive communication strategies report up to 25% fewer delays related to miscommunication and improved stakeholder satisfaction rates.

Digital collaboration tools featuring built-in approval workflows and comment tracking capabilities have revolutionized how project teams interact. These systems maintain detailed audit trails of all communications and decisions, providing accountability and reducing the risk of information loss. Additionally, mobile-friendly interfaces ensure that stakeholders can stay connected and responsive regardless of their location, supporting swift project advancement through improved coordination and decision-making efficiency.

Implementation Strategies and ROI Analysis

Technology Integration Framework

Successful technology integration in construction projects requires a systematic, well-planned approach. Begin with a comprehensive technology needs assessment, evaluating current workflows and identifying specific areas where digital solutions can add value. This initial phase should involve key stakeholders from various departments to ensure all requirements are captured.

Once needs are identified, develop a detailed implementation roadmap. This should include timeline benchmarks, resource allocation, and specific performance metrics. Consider both immediate operational needs and long-term scalability when selecting technology solutions. Integration should occur in phases to minimize disruption to ongoing projects.

Staff training is crucial for successful adoption. Establish a structured training program that includes both theoretical understanding and hands-on practice. Designate technology champions within each team to provide ongoing support and facilitate smooth transition.

Monitor system performance through predetermined KPIs and gather regular feedback from users. This data helps identify areas requiring adjustment and validates the technology’s impact on project efficiency. Common metrics include reduced documentation time, improved communication efficiency, and decreased error rates.

Implementation challenges often arise from resistance to change and technical integration issues. Address these proactively by maintaining open communication channels and having contingency plans in place. Regular system updates and maintenance schedules should be established to ensure optimal performance.

Finally, document best practices and lessons learned throughout the implementation process. This information becomes valuable for future technology integrations and helps establish standardized procedures across the organization.

Measuring Success and ROI

Effective measurement of project advancement requires a comprehensive understanding of key performance indicators (KPIs) and robust analytics frameworks. Successful construction firms implement both quantitative and qualitative metrics to evaluate project success, with particular emphasis on measuring project ROI through multiple dimensions.

Primary KPIs typically include schedule performance index (SPI), cost performance index (CPI), and earned value metrics. These indicators provide real-time insights into project health and help identify potential issues before they impact the bottom line. Quality metrics, such as defect rates and rework percentages, offer additional layers of performance measurement.

Financial success metrics should encompass both immediate returns and long-term value creation. This includes analyzing direct cost savings, resource utilization rates, and operational efficiency improvements. Advanced analytics platforms now enable teams to track these metrics in real-time, facilitating proactive decision-making and strategic adjustments.

Industry leaders are increasingly adopting balanced scorecard approaches that consider four key perspectives: financial performance, customer satisfaction, internal processes, and learning and growth. This holistic framework ensures comprehensive evaluation of project success beyond traditional cost and schedule metrics.

To maximize ROI assessment accuracy, organizations should establish clear baseline measurements at project initiation and conduct regular performance reviews throughout the project lifecycle. This approach enables better resource allocation, improved risk management, and more accurate forecasting for future projects.

As we look toward the future of construction project advancement, several key trends and developments are poised to reshape the industry landscape. The integration of digital technologies, sustainable practices, and collaborative methodologies has proven instrumental in driving project success and efficiency. Industry leaders who have embraced these innovations report significant improvements in project delivery times, cost management, and overall quality outcomes.

The adoption of data-driven decision-making processes, coupled with advanced project management tools, continues to demonstrate substantial returns on investment. Construction firms that have implemented comprehensive digital transformation strategies are experiencing up to 25% reduction in project delays and a 20% increase in productivity levels.

Looking ahead, emerging technologies such as artificial intelligence, machine learning, and robotics are expected to further revolutionize project advancement practices. The construction industry is moving toward more integrated approaches that combine traditional expertise with cutting-edge solutions. This evolution will require professionals to continuously update their skills and knowledge base to remain competitive.

Success in project advancement will increasingly depend on organizations’ ability to adapt to changing market conditions while maintaining focus on sustainability and efficiency. The future outlook suggests a growing emphasis on smart construction techniques, prefabrication, and modular construction methods. Organizations that invest in these areas while developing their workforce capabilities will be best positioned to lead the industry forward.

As we continue to navigate these changes, the importance of maintaining a balance between technological innovation and practical implementation remains paramount. The construction industry’s future success lies in its ability to embrace advancement while ensuring that new methodologies genuinely enhance project outcomes and deliver tangible value to stakeholders.