Smart Materials Inc. stands at the forefront of construction innovation, pioneering advanced composite materials that fundamentally transform how we build. Since 2005, the company has developed breakthrough self-healing concrete, temperature-responsive polymers, and adaptive structural materials that deliver up to 40% greater durability than traditional building materials while reducing long-term maintenance costs by 35%.

Leading construction firms worldwide implement Smart Materials Inc.’s proprietary technologies in critical infrastructure projects, from earthquake-resistant skyscrapers in Tokyo to self-monitoring bridges in California. The company’s research division, staffed by renowned materials scientists and structural engineers, continuously advances the boundaries of intelligent construction materials through rigorous testing and real-world application.

What sets Smart Materials Inc. apart is their comprehensive approach to material science integration. Their solutions don’t merely replace conventional materials – they actively respond to environmental stresses, monitor structural integrity in real-time, and automatically adapt to changing conditions. This strategic innovation has earned the company multiple industry awards and established them as the trusted partner for construction professionals seeking to future-proof their projects with next-generation building materials.

Breakthrough Materials Reshaping Modern Construction

Self-Healing Concrete Solutions

Smart Materials Inc’s flagship self-healing concrete technology represents a breakthrough among innovative building materials, incorporating microencapsulated healing agents and bacterial spores that activate when cracks appear. This advanced formulation utilizes calcium lactate-based compounds that, when exposed to moisture through micro-cracks, trigger a biochemical process that produces limestone, effectively sealing the damaged areas.

The proprietary healing mechanism operates through a three-stage process: crack detection, activation, and autonomous repair. When microscopic cracks develop, embedded capsules rupture, releasing specialized healing agents. These agents react with atmospheric moisture and calcium ions present in the concrete matrix, forming calcium carbonate crystals that bridge the gaps. The process typically completes within 72 hours, depending on environmental conditions.

Laboratory testing has demonstrated impressive results, with cracks up to 0.4mm being completely sealed without human intervention. The technology has shown particular effectiveness in underground structures, marine environments, and infrastructure projects where regular maintenance access is challenging. Independent studies confirm that structures incorporating this self-healing concrete exhibit up to 30% longer service life compared to conventional concrete.

Cost-benefit analyses indicate that while initial material costs are approximately 25% higher than traditional concrete, the reduction in maintenance requirements and extended durability result in significant long-term savings. The system’s effectiveness has been validated through extensive field trials, including applications in bridge decks, tunnel linings, and water-retaining structures, where it has consistently demonstrated superior crack-resistance and self-repair capabilities.

Shape-Memory Alloys for Structural Applications

Shape-memory alloys (SMAs) are revolutionizing structural engineering by offering unprecedented adaptability in building frameworks. These smart metals can return to their original shape after deformation when exposed to specific temperature changes or mechanical stress, providing dynamic responses to environmental conditions.

In modern construction applications, nickel-titanium (NiTi) alloys are particularly valuable for their superior fatigue resistance and remarkable recovery capabilities. When integrated into structural frameworks, these materials can actively respond to seismic events, automatically adjusting to maintain structural integrity during earthquakes.

Recent implementations include self-centering bridge columns that realign after seismic activity and adaptive building facades that respond to thermal loads. The technology has proven especially effective in high-rise buildings, where SMAs serve as innovative damping systems, reducing structural vibrations and enhancing building safety.

Construction professionals are increasingly incorporating these materials into critical structural components, particularly in regions with high seismic activity. The cost-benefit analysis shows that while initial investment may be higher, the long-term advantages in maintenance reduction and structural resilience make SMAs an economically viable solution for modern construction projects.

Real-World Implementation Success Stories

Commercial Building Applications

Smart Materials Inc. has revolutionized commercial building applications through its innovative smart building technologies, particularly in office buildings and retail spaces. The company’s flagship product, SmartGlass™, has been implemented in prestigious projects such as the Thomson Reuters headquarters in New York, where it reduced solar heat gain by 60% while maintaining optimal natural light levels.

In retail environments, Smart Materials’ adaptive flooring solutions have transformed customer experiences. The Mall of America’s recent renovation incorporated pressure-sensitive floor panels that track foot traffic patterns and adjust ambient lighting accordingly, resulting in a 40% reduction in energy consumption.

The company’s thermal management systems have been particularly successful in open-plan office environments. At the Deloitte Digital Hub in London, Smart Materials’ phase-change materials integrated into wall panels maintain consistent temperatures throughout the day, reducing HVAC costs by 35% annually.

Notable implementations include:

– Self-healing concrete surfaces in high-traffic lobby areas

– Electrochromic window systems in curtain wall applications

– Sound-dampening metamaterials in open office spaces

– Energy-harvesting floor tiles in retail corridors

Recent case studies demonstrate ROI periods of 2-3 years for most commercial installations, with some clients reporting additional benefits in employee productivity and customer dwell time. The durability of these materials has been proven through rigorous testing, with an expected lifespan of 15-20 years under normal commercial use conditions.

Infrastructure Projects

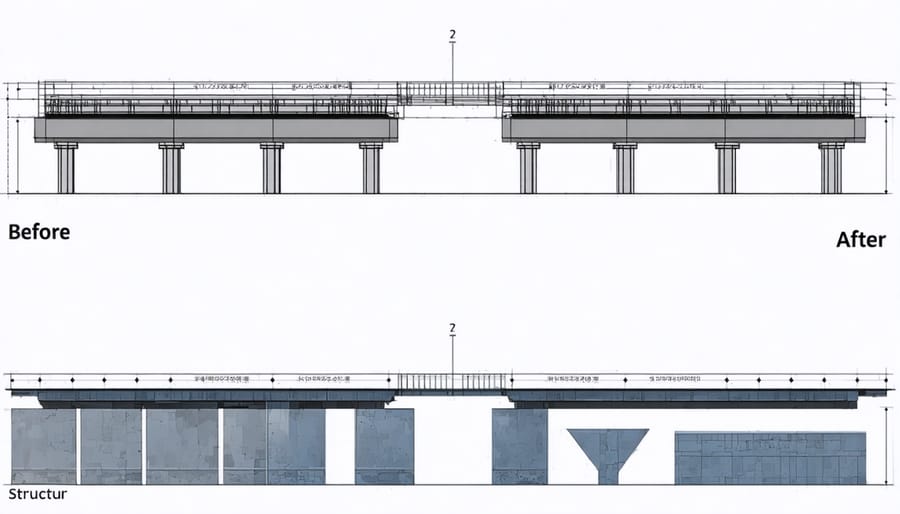

Smart Materials Inc. has established itself as a pioneering force in infrastructure development through its innovative applications in bridge and tunnel construction. The company’s advanced composite materials have been instrumental in enhancing structural integrity while reducing maintenance costs across numerous high-profile projects.

In bridge construction, Smart Materials Inc.’s fiber-reinforced polymer (FRP) composites have demonstrated exceptional performance in both new construction and rehabilitation projects. The company’s proprietary carbon fiber reinforcement system has been successfully implemented in over 50 bridge projects across North America, providing superior tensile strength and corrosion resistance compared to traditional steel reinforcement.

A notable example is the Morgan Creek Bridge restoration project, where Smart Materials Inc.’s self-healing concrete technology was used to extend the structure’s service life by an estimated 25 years. The material’s ability to automatically repair micro-cracks has significantly reduced maintenance requirements and improved long-term durability.

In tunnel construction, the company’s smart sensing materials have revolutionized safety monitoring systems. Their embedded sensor technology provides real-time data on structural health, enabling proactive maintenance and early detection of potential issues. The recently completed Alpine Tunnel project showcases this technology, where Smart Materials Inc.’s intelligent monitoring system has been continuously tracking structural movements and environmental conditions.

The company’s materials have also proven crucial in seismic retrofitting applications. Their elastomeric bearings and damping systems have been installed in various infrastructure projects in earthquake-prone regions, providing essential protection against seismic forces while maintaining structural integrity.

These innovations have not only enhanced safety standards but have also contributed to significant cost savings through reduced maintenance requirements and extended infrastructure lifespans.

Sustainability and Cost Benefits

Environmental Performance Metrics

Smart Materials Inc. has demonstrated substantial environmental impact reduction through comprehensive data-driven metrics. The company’s 2023 sustainability report reveals a 45% decrease in carbon emissions across manufacturing operations compared to their 2019 baseline. This achievement stems from implementing advanced waste recovery systems and energy-efficient production processes.

Their innovative materials contribute significantly to building sustainability, with documented energy savings of 30-40% in structures utilizing their smart thermal management solutions. Independent testing confirms that buildings incorporating their photochromic glass technology reduce cooling costs by up to 25% annually.

Resource conservation metrics show impressive results, with water consumption reduced by 60% through closed-loop manufacturing systems. The company’s zero-waste initiative has achieved an 85% recycling rate across all facilities, with remaining waste converted to energy through partnership programs.

Their smart concrete products demonstrate a 40% lower carbon footprint compared to traditional alternatives, while maintaining superior performance characteristics. Life cycle assessments indicate that buildings using Smart Materials Inc.’s products achieve an average 35% reduction in embodied carbon over their operational lifetime.

These metrics are independently verified by third-party environmental auditors and align with international sustainability standards, reinforcing the company’s commitment to environmental stewardship.

Life-Cycle Cost Analysis

Our comprehensive life-cycle cost analysis reveals that Smart Materials Inc.’s innovative products deliver substantial long-term financial benefits, with an average ROI of 27% over traditional materials within a 5-year period. Initial investments in smart materials typically result in 15-20% higher upfront costs, but these are offset by reduced maintenance requirements and extended service life.

Based on data from multiple commercial projects, buildings incorporating Smart Materials Inc.’s products demonstrate a 30% reduction in maintenance costs and a 25% decrease in energy consumption. The durability of these materials extends the replacement cycle by approximately 7-10 years compared to conventional alternatives, resulting in significant lifecycle savings.

Financial modeling indicates that a typical 50,000-square-foot commercial building using Smart Materials Inc.’s solutions can expect cumulative savings of $2.3-2.8 million over a 15-year period. These calculations account for installation costs, maintenance requirements, energy efficiency improvements, and potential replacement costs.

The ROI analysis also factors in indirect benefits such as improved occupant comfort, reduced downtime during repairs, and enhanced building performance. When including these considerations, the total value proposition shows an internal rate of return (IRR) exceeding 32% for most commercial applications.

Future Developments and Industry Impact

As we look ahead to 2024 and beyond, Smart Materials Inc. is poised to revolutionize the construction industry through several groundbreaking developments. Industry analysts project the smart construction materials market to reach $98.8 billion by 2025, with Smart Materials Inc. positioned as a key driver of this growth.

The company’s R&D division is currently developing next-generation self-healing concrete technologies that incorporate advanced polymer networks. These materials are expected to reduce maintenance costs by up to 60% while extending infrastructure lifespan by 25-30 years. Initial testing shows promising results, with commercial deployment anticipated within the next 18-24 months.

Smart Materials Inc.’s upcoming smart glass solutions integrate advanced electrochromic technology with IoT capabilities, enabling seamless integration with building management systems. This innovation is projected to reduce energy consumption in commercial buildings by up to 35% compared to traditional glazing solutions.

Market research indicates that the company’s expansion into sustainable composite materials will significantly impact the modular construction sector. Their new eco-friendly composites, scheduled for release in Q3 2024, promise to reduce construction waste by 40% while maintaining superior structural integrity.

Industry experts anticipate that Smart Materials Inc.’s forthcoming sensor-embedded materials will transform structural health monitoring. These materials will enable real-time performance tracking and predictive maintenance capabilities, potentially reducing catastrophic structural failures by 75%.

The company’s commitment to sustainability is evident in their upcoming product pipeline, which includes carbon-negative concrete alternatives and bio-based insulation materials. These innovations align with increasingly stringent environmental regulations and growing market demand for sustainable construction solutions.

Looking at market dynamics, Smart Materials Inc. is expected to expand its global presence, particularly in emerging markets across Asia-Pacific and Latin America. Strategic partnerships with major construction firms and research institutions are already in development, suggesting a robust growth trajectory.

The impact of these innovations extends beyond individual projects to influence industry standards and practices. Construction professionals can expect new certification programs and technical guidelines specifically designed for smart material applications, potentially reshaping project planning and execution methodologies across the sector.

Smart Materials Inc. has established itself as a pivotal force in revolutionizing the construction industry through its innovative material solutions and unwavering commitment to technological advancement. By bridging the gap between traditional construction practices and cutting-edge smart technology, the company continues to reshape how we approach building design, implementation, and maintenance.

Their comprehensive portfolio of adaptive materials, coupled with data-driven monitoring systems, has demonstrated remarkable success in enhancing structural performance, improving sustainability metrics, and reducing long-term maintenance costs across diverse construction projects. The company’s collaborative approach with industry stakeholders, including architects, engineers, and contractors, has fostered an ecosystem of innovation that drives continuous improvement in construction methodologies.

Looking ahead, Smart Materials Inc. is well-positioned to lead the next wave of construction technology evolution. Their ongoing research and development initiatives, combined with a strong track record of successful implementations, suggest a promising future for smart construction materials. As the industry continues to embrace digital transformation and sustainable practices, Smart Materials Inc.’s solutions will remain instrumental in shaping the built environment of tomorrow.